Composite high-speed rail waterproof material

A waterproof material and high-speed rail technology, applied in the field of coatings, can solve the problems of reducing the utilization rate of bridge steel bars, reducing the bearing area of steel bars, and aggravating the freeze-thaw damage of concrete, achieving simple and stable construction technology, excellent mechanical properties, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

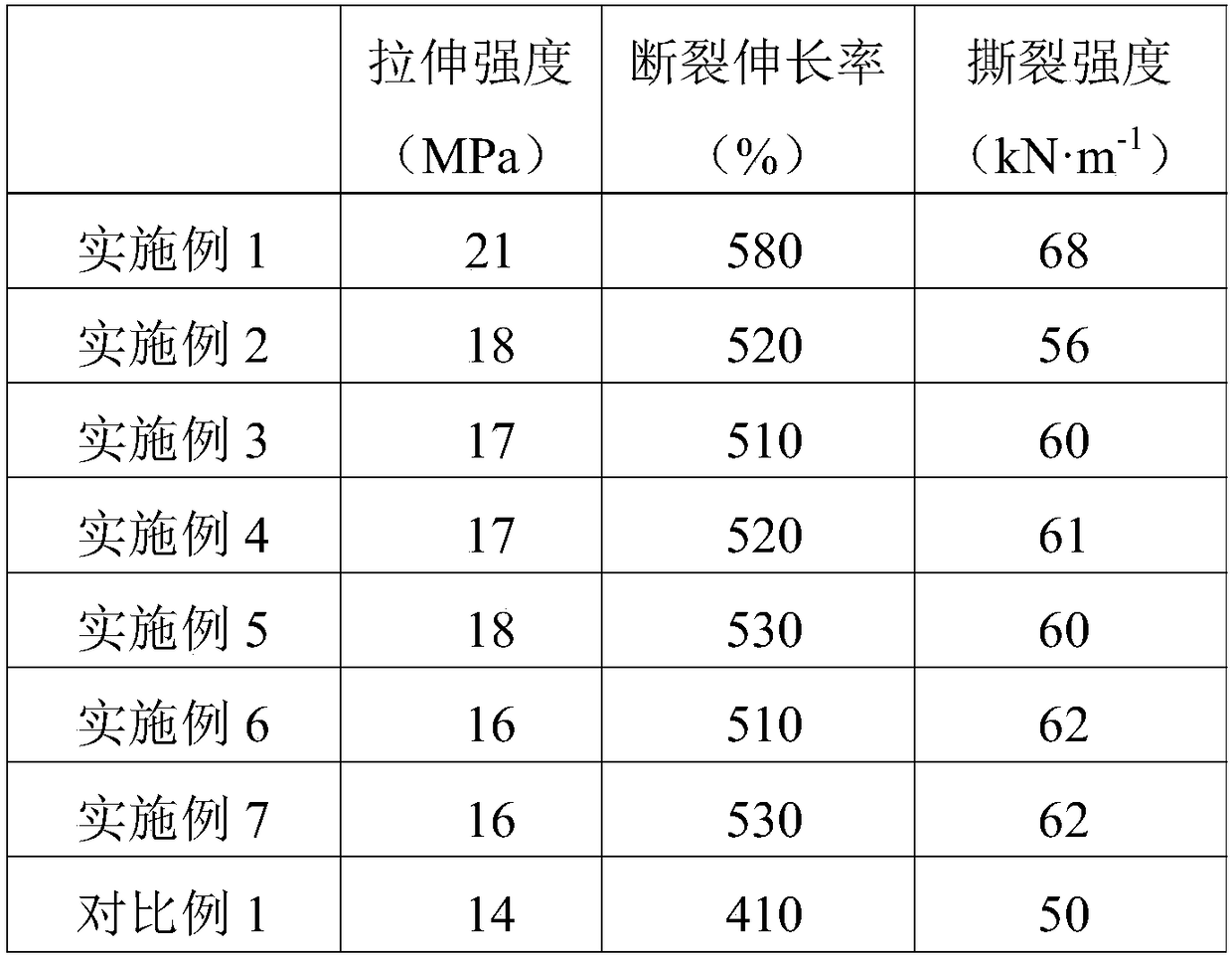

Examples

Embodiment 1

[0038] Composite high-speed iron waterproof material, the mass ratio of component A and component B is 1:1. Raw materials of component A (parts by weight): 100 parts of polyether DL-3000D, 5 parts of triethyl citrate, 14 parts of 4,4'-methylene bis(phenylisocyanate), graphene / methanesulfonic acid 10 parts of solution, 6 parts of inorganic antibacterial agent, 3 parts of flame retardant. B component raw materials (parts by weight): 58 parts of amino-terminated polyether D400, 18 parts of 4,4'-diamino-3,3'-dichlorodiphenylmethane, 9 parts of 1,3-diaminomethylcyclohexane 7 parts, amino-terminated polyether T5000 7 parts.

[0039] The inorganic antibacterial agent is obtained by uniformly stirring and mixing silver chloride, silver tungstate and zinc carbonate in a mass ratio of 1:1:1.

[0040] The flame retardant is obtained by uniformly stirring and mixing triphenyl phosphate, hexabromocyclododecane, and dimethyl methyl phosphate in a mass ratio of 1:1:1.

[0041] Preparation...

Embodiment 2

[0046]It is basically the same as in Example 1, except that the inorganic antibacterial agent is obtained by stirring and mixing uniformly silver tungstate and zinc carbonate at a mass ratio of 1:1. Obtain the composite high-speed iron waterproof material of embodiment 2.

Embodiment 3

[0048] It is basically the same as in Example 1, except that the inorganic antibacterial agent is obtained by stirring and mixing uniformly silver chloride and zinc carbonate at a mass ratio of 1:1. Obtain the composite high-speed rail waterproof material of embodiment 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com