Waterproof material for high-speed rail

A waterproof material and high-speed rail technology, applied in the field of coatings, can solve the problems of reducing the bearing area of steel bars, reducing the utilization rate of steel bars in bridges, and aggravating the freeze-thaw damage of concrete, achieving excellent mechanical properties, simple and stable construction process, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

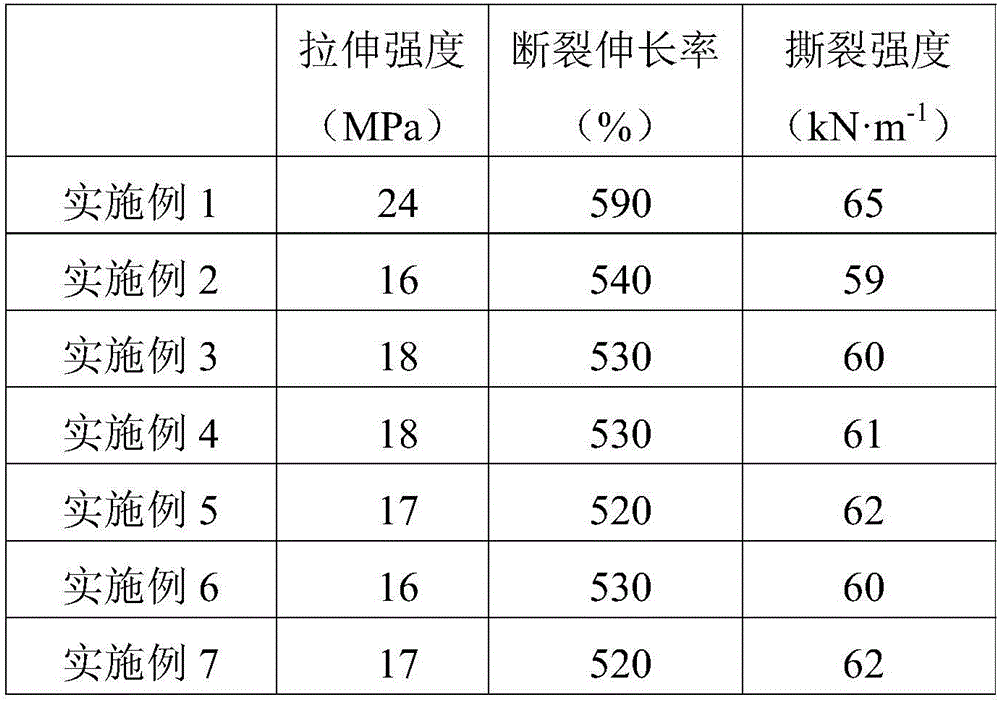

Examples

Embodiment 1

[0036] For high-speed iron waterproof materials, the mass ratio of component A and component B is 1:1. Raw materials of component A (parts by weight): 100 parts of polyether DL-2000D, 5 parts of triisooctyl phosphite, 14 parts of 4,4'-methylene bis(phenylisocyanate), graphene / methanesulfonate 10 parts of acid solution, 6 parts of triethyl citrate. Component B raw materials (parts by weight): 66 parts of amino-terminated polyether, 30 parts of amine chain extender.

[0037] The amino-terminated polyether is obtained by uniformly stirring and mixing amino-terminated polyether D2000, amino-terminated polyether D400, and amino-terminated polyether T403 at a mass ratio of 1:1:1.

[0038] The amine chain extender is composed of 4,4'-diamino-3,3'-dichlorodiphenylmethane, 1,3-diaminomethylcyclohexane, and diethyltoluenediamine in a mass ratio of 1:1:1 Stir and mix to get even.

[0039] Preparation of high-speed rail waterproof material:

[0040] (1) Add polyether DL-2000D and tri-...

Embodiment 2

[0044] It is basically the same as Example 1, except that the amino-terminated polyether is obtained by stirring and mixing the amino-terminated polyether D400 and the amino-terminated polyether T403 at a mass ratio of 1:1. . Obtain the high-speed iron waterproof material of embodiment 2.

Embodiment 3

[0046] It is basically the same as Example 1, except that the amino-terminated polyether is obtained by stirring and mixing the amino-terminated polyether D2000 and the amino-terminated polyether T403 at a mass ratio of 1:1. . Obtain the high-speed iron waterproof material of embodiment 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com