A low-viscosity high-temperature-resistant vacuum pressure solvent-free impregnation resin and its preparation method

A technology of vacuum pressure and resin impregnation, applied in the field of electrical insulating resin, can solve the problems of high price, gel, affecting production efficiency, etc., and achieve the effect of high heat resistance index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A low-viscosity high temperature resistant vacuum pressure solvent-free impregnating resin, its components and weight percentages are as follows: distillation grade epoxy resin is 30% of bisphenol A type epoxy resin, 40% of polyimide resin, and the reactive diluent is ethylene 15% of base toluene, 4% of hydroquinone as polymerization inhibitor, 10% of tung oil anhydride as curing agent and 1% of aluminum acetylacetonate as curing accelerator.

Embodiment 2

[0026] A low-viscosity, high-temperature, vacuum-pressure-resistant, solvent-free impregnating resin, its components and percentages by weight are as follows: Distilled-grade epoxy resin is 27% of novolac epoxy resin, 37% of polyimide resin, 18% of vinyl toluene, polymerization inhibitor The agent is hydroquinone 5%, the curing agent is tung oil anhydride 11%, and the curing accelerator is aluminum acetylacetonate 2%.

Embodiment 3

[0028] A low-viscosity, high-temperature, vacuum-pressure-resistant, solvent-free impregnating resin. Its components and percentages by weight are as follows: distilled-grade epoxy resin is 25% of bisphenol A epoxy resin, 40% of polyimide resin, and reactive diluent is poly Dipropylene phthalate 20%, polymerization inhibitor is hydroquinone 3%, curing agent is methyl hexahydrophthalic anhydride 10% and curing accelerator is aluminum acetylacetonate and tri-(dimethylaminomethyl ) phenol mixture 2%.

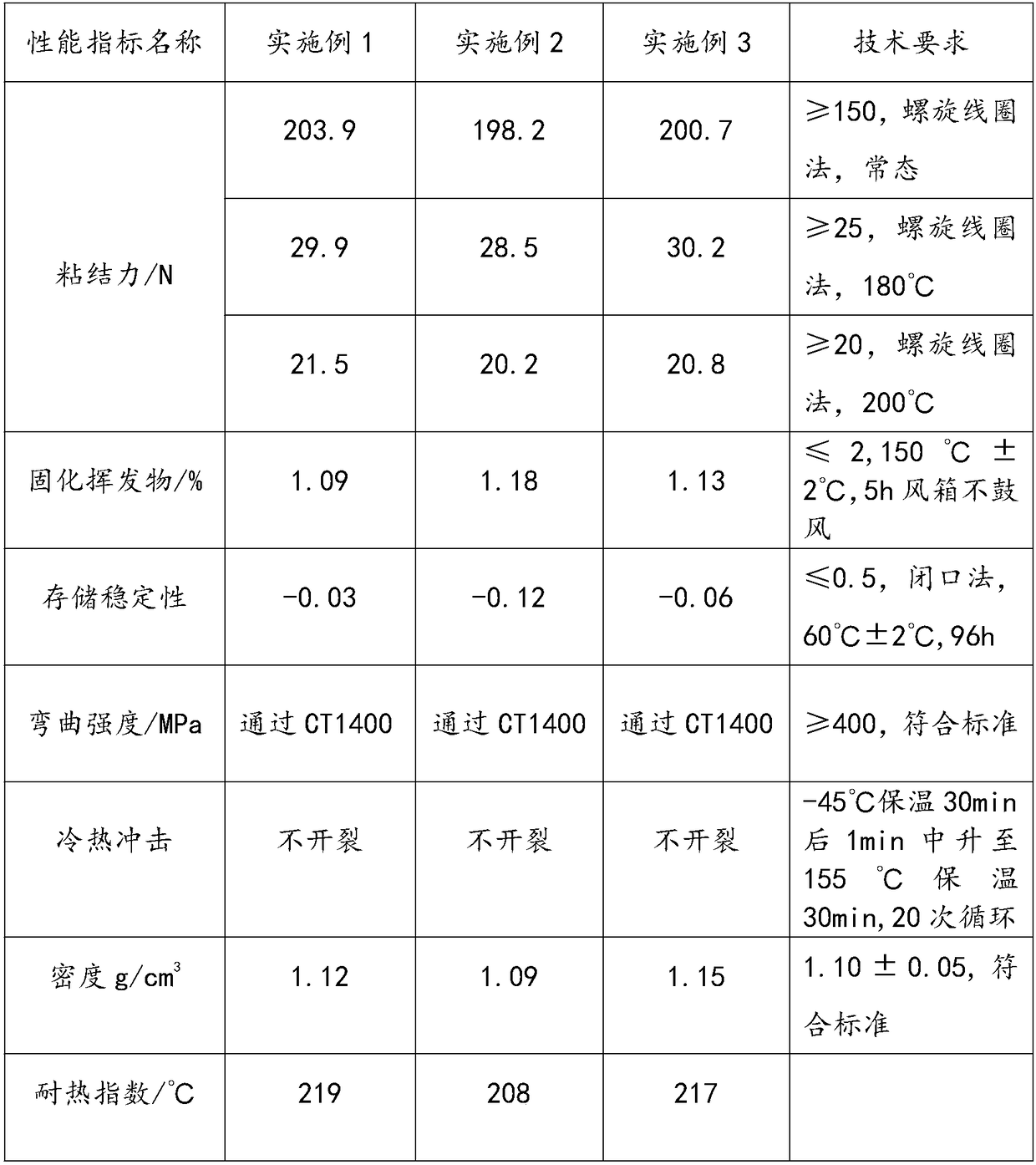

[0029] Table 1 is the performance test data of the solvent-free impregnating resin of Examples 1-3

[0030]

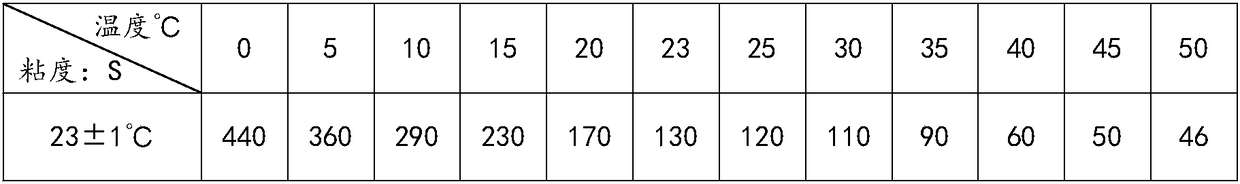

[0031] Table 2 is a solvent-free impregnating resin resin viscosity change table with temperature:

[0032]

[0033] Below 23°C, 4# cannot be measured accurately, and the data is for reference only.

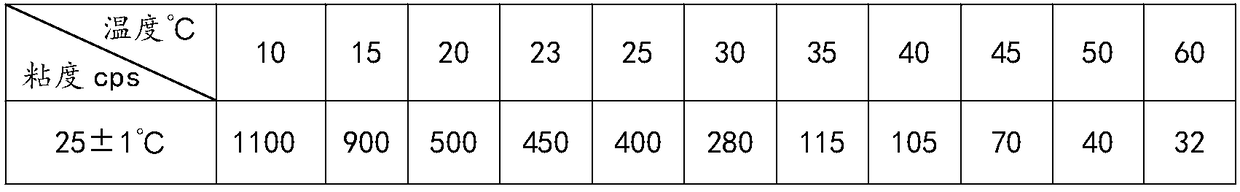

[0034] Table 3 is the variation table of solvent-free impregnation resin rotational viscosity with temperature:

[0035]

[0036] The above-mentioned preparation m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com