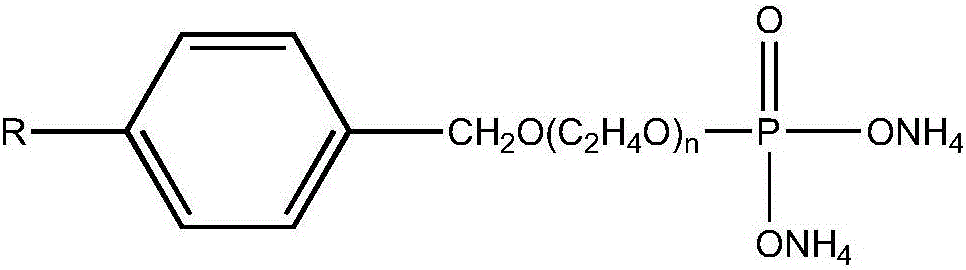

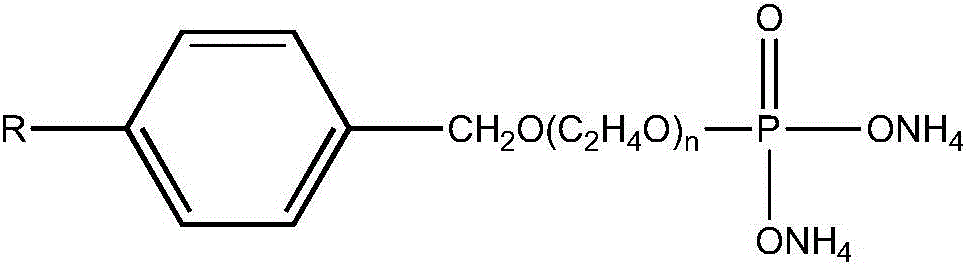

Alkyl benzoic alcohol polyoxyethylene ether ammonium phosphate and preparation method thereof

A technology of alkyl benzyl alcohol and polyoxyethylene ether, used in chemical instruments and methods, phosphorus organic compounds, organic chemistry, etc. good wetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

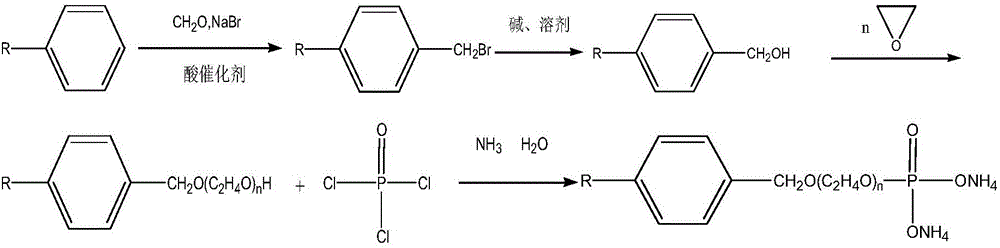

Method used

Image

Examples

Embodiment 1

[0024] A kind of APEO-free nonylbenzyl alcohol polyoxyethylene ether (9) ammonium phosphate emulsifier, its preparation method is as follows:

[0025] Step a. In the reaction kettle, add nonylbenzene, paraformaldehyde, and sodium bromide, react at 70°C for 6-8 hours under the action of an acid catalyst, then pour into ice water, and wash the organic solvent with water and saturated sodium bicarbonate solution in sequence layer, and distilled under reduced pressure to obtain p-nonylbenzyl bromide;

[0026] Step b. In the reaction kettle, add p-nonylbenzyl bromide, methanol, and potassium hydroxide, raise the temperature to a reflux state, and keep the reflux reaction at this temperature for 2 hours to obtain p-nonylbenzyl alcohol;

[0027] Step c, drop into p-nonylbenzyl alcohol and catalyst potassium hydroxide in the reactor, then heat up and vacuum dehydrate; after dehydration is completed, feed nitrogen replacement, press p-nonylbenzyl alcohol / ethylene oxide in a molar ratio...

Embodiment 2

[0031] A kind of APEO-free nonylbenzyl alcohol polyoxyethylene ether (12) ammonium phosphate emulsifier, its preparation method is as follows:

[0032] Step a. In the reaction kettle, add nonylbenzene, paraformaldehyde, and sodium bromide, react at 70°C for 6-8 hours under the action of an acid catalyst, then pour into ice water, and wash the organic solvent with water and saturated sodium bicarbonate solution in sequence layer, and distilled under reduced pressure to obtain p-nonylbenzyl bromide;

[0033] Step b. In the reaction kettle, add p-nonylbenzyl bromide, methanol, and potassium hydroxide, raise the temperature to a reflux state, and keep the reflux reaction at this temperature for 2 hours to obtain p-nonylbenzyl alcohol;

[0034] Step c, drop into p-nonylbenzyl alcohol and catalyst potassium hydroxide in the reactor, then heat up and vacuum dehydrate; after dehydration is completed, feed nitrogen replacement, press p-nonylbenzyl alcohol / ethylene oxide in a molar rati...

Embodiment 3

[0038] A kind of dodecylbenzyl alcohol polyoxyethylene ether (4) ammonium phosphate emulsifier without APEO, its preparation method is as follows:

[0039] Step a. In the reaction kettle, add dodecylbenzene, paraformaldehyde, and sodium bromide, react at 70°C for 6 to 8 hours under the action of an acid catalyst, then pour into ice water, and then use water and saturated sodium bicarbonate solution The organic layer was washed and distilled under reduced pressure to obtain p-dodecylbenzyl bromide;

[0040] Step b. In the reaction kettle, add p-dodecylbenzyl bromide, methanol, and potassium hydroxide, heat up to a reflux state, and keep the reflux reaction at this temperature for 2 hours to obtain p-dodecylbenzyl alcohol;

[0041] Step c, drop into p-dodecylbenzyl alcohol and catalyst potassium hydroxide in the reactor, then heat up and vacuum dehydrate; after dehydration is completed, feed nitrogen replacement, press p-dodecylbenzyl alcohol / ethylene oxide Slowly feed ethylene o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com