A kind of synthetic method of fluoran compound and its catalyst

A synthesis method and compound technology, applied in the direction of organic chemistry, triarylmethane dyes, etc., can solve the problems of difficult separation of colors of products, limit the production scale of products, increase the burden of three wastes treatment, etc., achieve cheap raw materials, reduce the generation and production of tar The effect of process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

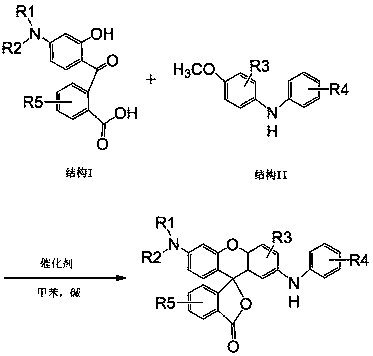

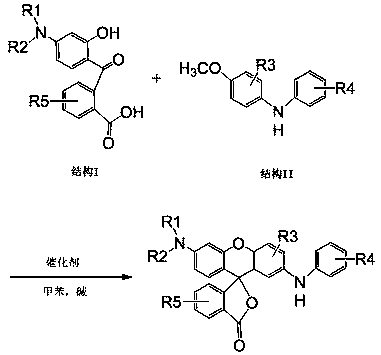

Method used

Image

Examples

Embodiment 1

[0016] Add 240g toluene, 37.6g 98% 2-(2-hydroxyl-4-diethylaminobenzoyl)benzoic acid (self-made, the same below) and 0.18 g catalyst (preparation of catalyst, graphene oxide by mass ratio: Al 2 o 3 : CuO=0.1:10:0.025, first add 10g of alumina to 50ml of deionized water, stir at 80°C for 1h, and at the same time disperse 0.1g of graphene oxide and 0.025g of copper oxide in 50ml of deionized water by ultrasonic, and then dissolve the dispersion Add the above alumina system, continue to stir for 3 hours, centrifuge, dry the solid in an oven, grind it into powder, then put the solid powder in a muffle furnace and slowly heat up from room temperature to 300 ° C for 5 hours, and then lower it to room temperature. The solid powder is the catalyst mentioned above, sealed and stored for future use), stir evenly, keep the temperature at 25°C and add 27.3g 98% 2,3′-dimethyl-4-methoxydiphenylamine dropwise (self-made, the same below) , after dripping, the mixture was warmed up to reflux ...

Embodiment 2

[0018] Add 240g toluene, 37.6g 98% 2-(2-hydroxyl-4-diethylaminobenzoyl) benzoic acid and 0.18g catalyzer in the reactor with condensation water separator, agitator and thermometer (preparation of catalyst , by mass ratio of graphene oxide: Al 2 o 3 : ZnO=0.1:10:0.025, the preparation method is the same as in Example 1), stir evenly, keep the temperature at 25°C, add 27.3g 98% 2,3′-dimethyl-4-methoxydiphenylamine dropwise, dropwise Then heat the mixture to reflux temperature and react for about 5 hours. During the process, the generated water is separated. After the reaction is completed, the catalyst is recovered by filtration while it is hot (applied after being washed with a solvent). The obtained organic phase is added to the flask together with 180g of 25% sodium hydroxide aqueous solution. Then fully stirred and refluxed for 1 h, separated the upper organic phase, washed the organic phase with hot water, concentrated and recovered the solvent, and recrystallized the resi...

Embodiment 3

[0020] Add 240g toluene, 37.6g 98% 2-(2-hydroxyl-4-diethylaminobenzoyl) benzoic acid and 0.18g catalyzer in the reactor with condensation water separator, agitator and thermometer (preparation of catalyst , by mass ratio of graphene oxide: Al 2 o 3 : Fe 2 o 3 =0.1:10:0.025, the preparation method is the same as in Example 1), stir evenly, keep the temperature at 25°C, add 27.3g98% 2,3′-dimethyl-4-methoxydiphenylamine dropwise, and mix the mixture Raise the temperature to reflux temperature and react for about 5 hours. During the process, remove the generated water. After the reaction is over, filter and recover the catalyst while it is hot (after washing with solvent, apply mechanically). The obtained organic phase is added to the flask together with 180g of 25% sodium hydroxide aqueous solution, and then fully stirred Reflux for 1 h, separate the upper organic phase, wash the organic phase with hot water, concentrate and recover the solvent, and recrystallize the residue w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com