Coal chemical industry waste water treatment technology

A coal chemical wastewater and treatment process technology, applied in the direction of oxidation water/sewage treatment, gaseous discharge wastewater treatment, water/sewage treatment, etc., can solve the problems of high pollution, unstable operation, and restricting the development of the coal chemical industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

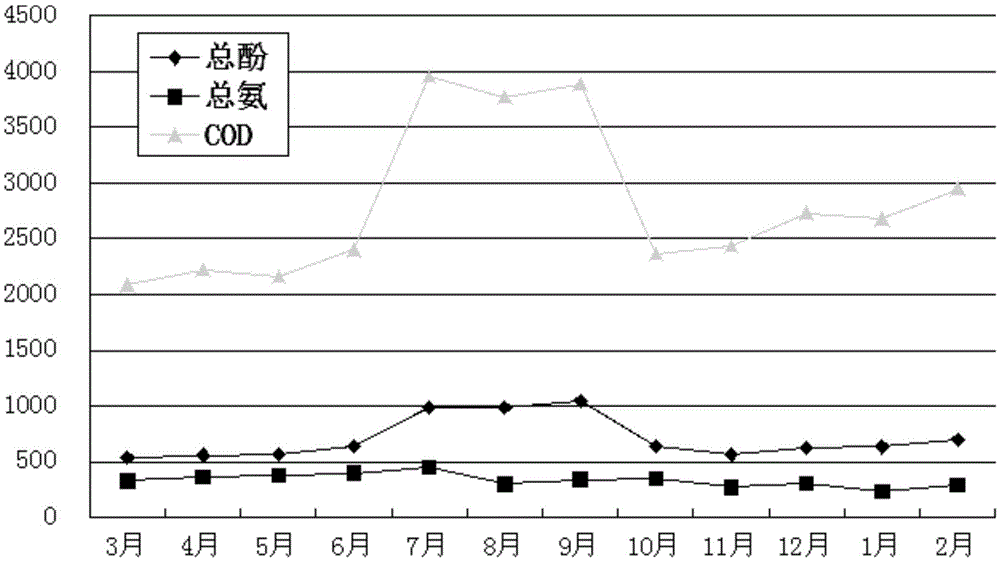

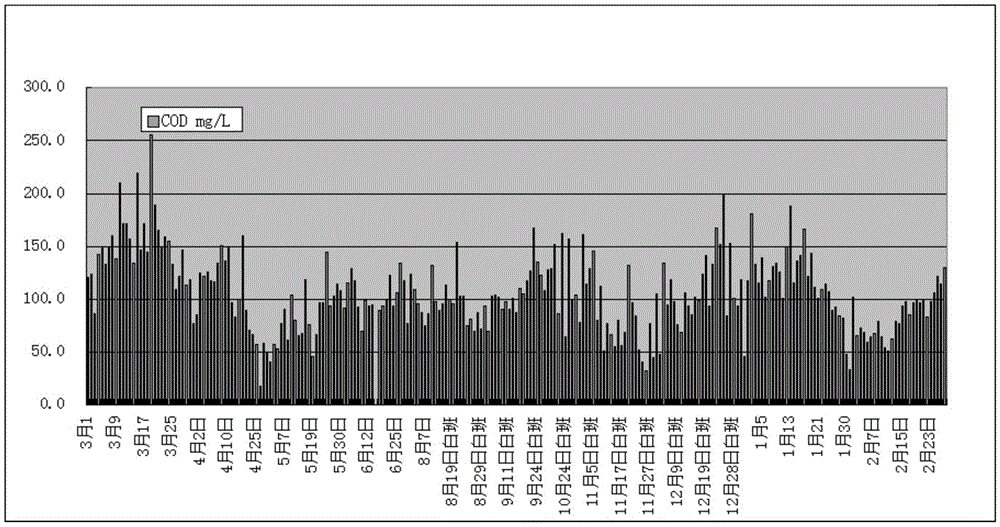

[0087] Operation situation of the treatment process of coal chemical industry waste water of the present invention within 12 months

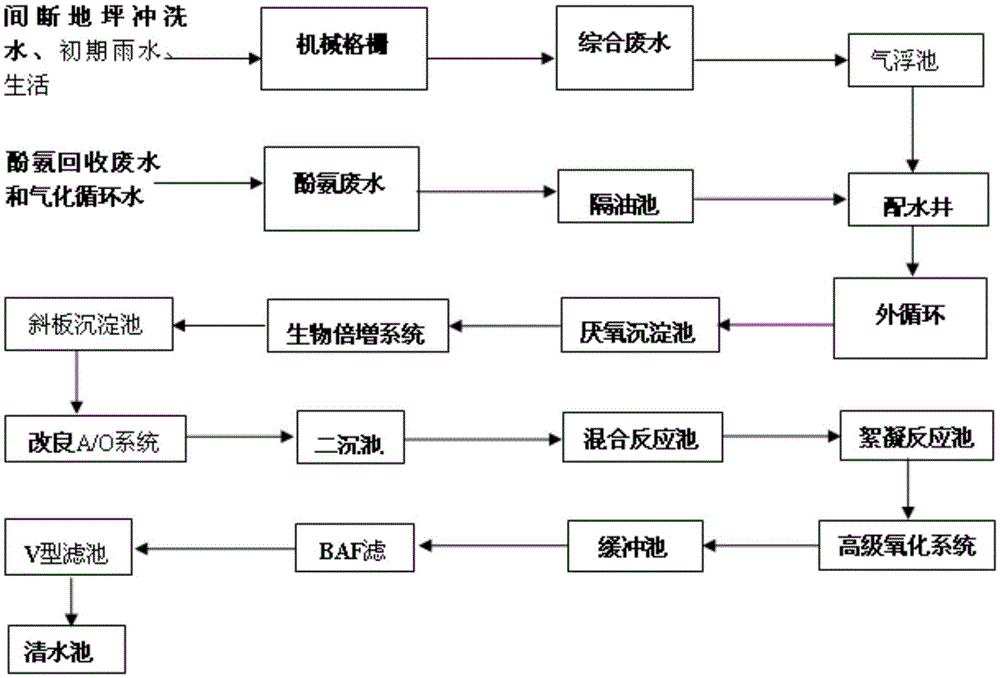

[0088] Firstly, the organic wastewater in the coal chemical industry wastewater is deaminated and deacidified in a single tower, and the wastewater is divided into cold and hot streams and enters the sewage stripper from the upper and middle upper parts respectively, and the CO 2 、H 2 S and other acid gases and a small amount of ammonia and water vapor enter the subsequent treatment device or torch incineration; the ammonia water vapor extracted from the side line enters the third-stage fractional condensation, and condenses back to part of the water and a small amount of ammonia and CO 2 , the rich ammonia gas enters the ammonia refining section to be processed into liquid ammonia. After deacidification, the liquid in the waste water stripping tower is cooled to about 40°C and then enters the extraction tower from the upper part, and is subjec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com