Preparing method and application of load type environment-friendly iron-aluminum alloy

An iron-aluminum alloy and load-type technology, which is applied in the field of preparation of load-type iron-aluminum alloys, can solve the problems of secondary pollution, pollution, entry into the soil environment, etc., to reduce the generation of polluting wastes, the process is simple and reliable, and the application is expanded. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

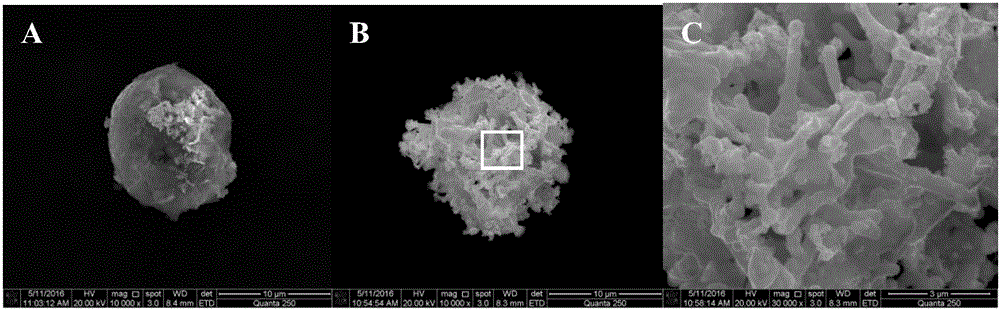

Image

Examples

Embodiment 1

[0022] a. Take a certain amount of aluminum powder with a particle size of 25 microns, put it in a deoxygenated water beaker containing 5% aluminum special cleaning agent, put the beaker into an ultrasonic cleaning tank with a water temperature of 60°C for 15 minutes, and remove the surface of the aluminum powder Oil stains, oxides, etc., were filtered under nitrogen protection, rinsed with absolute ethanol several times, and dried in a vacuum oven for use.

[0023] b. Prepare 200ml of 0.1mol / L acetic acid solution in a three-necked beaker, heat it to 70°C, put 10g of the above-mentioned dried aluminum powder under stirring conditions, and react for a period of time to form a hydrogen reducing atmosphere.

[0024] c. Heat and dissolve the PASP gel with a molecular weight of 15,000-20,000 in pure water to prepare a PASP solution with a mass fraction of 0.01%, mix it with a mass concentration of 60g / L ferrous chloride solution, and set the volume to 100ml , to obtain a mixed sol...

Embodiment 2

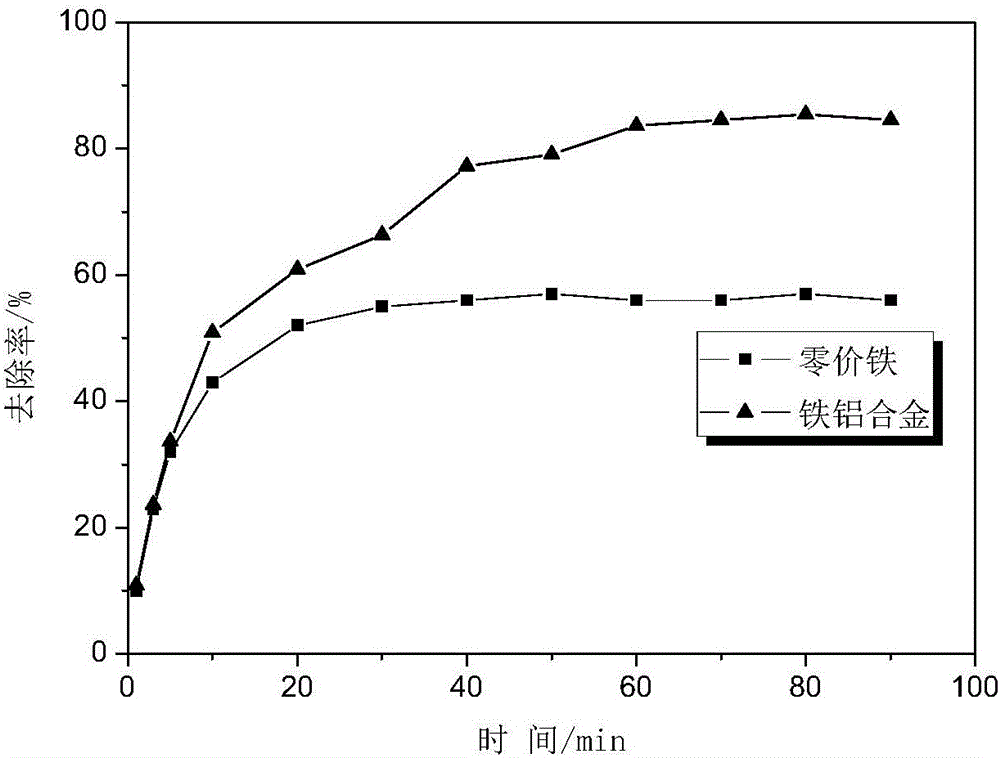

[0027] Cr 6+ removal rate test. Get 0.2g of the material and add it to 100ml of simulated Cr 6+ In the heavy metal polluted wastewater with a concentration of 50mg / L, divide it into three groups of parallel experiments, put it into a constant temperature shaking box at 35°C for reaction, and take samples at regular intervals to measure Cr in the water body. 6+ Concentration, to get the Cr of the material 6+ Remove curves. Replace the loaded iron-aluminum alloy with zero-valent iron and carry out the experiment according to the above steps to obtain the Cr of zero-valent iron 6+ Remove the curve and compare the two, the result is as follows figure 2 shown. from figure 2 It can be seen that: the material prepared by the present invention has a higher removal rate in a shorter time than pure zero-valent iron, and the reaction is rapid.

Embodiment 3

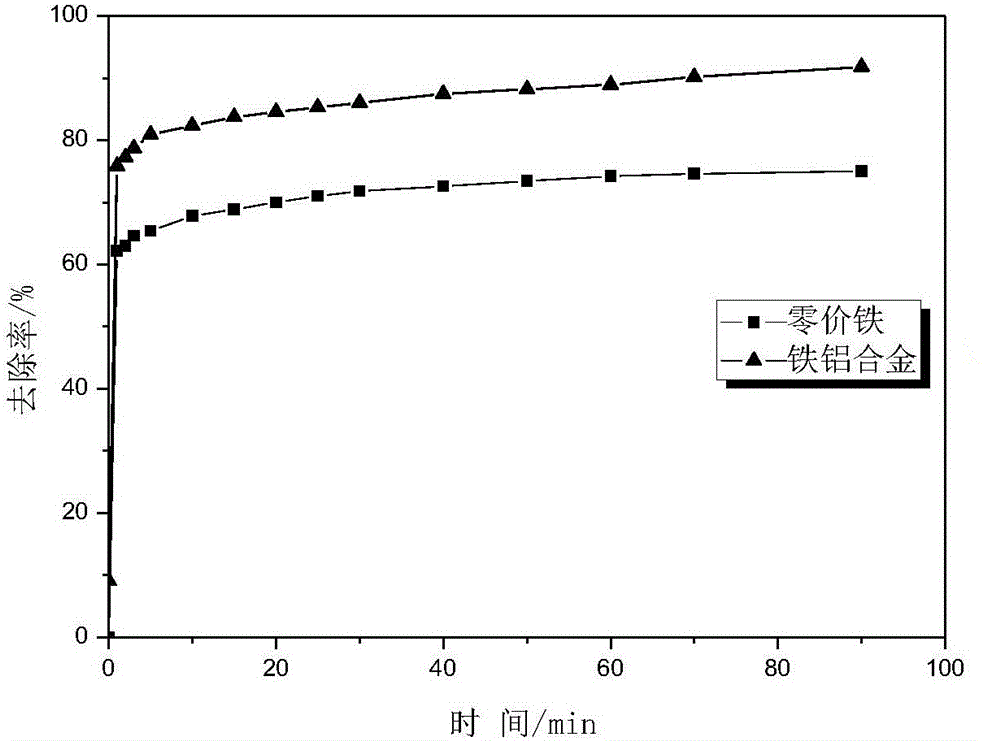

[0029] The iron-aluminum alloy prepared by the present invention is tested for the removal rate of nitrate. Take 0.2g of the material and add it to 100ml of heavy metal-contaminated wastewater with a simulated nitrate concentration of 100mg / L, divide it into three groups of parallel experiments, put it into a constant temperature oscillation box at 35°C for reaction, and take samples at regular intervals to measure the water body The nitrate removal curve of the material was obtained at the middle nitrate concentration. Replace the iron-aluminum alloy with zero-valent iron to carry out the experiment according to the above steps, and obtain the nitrate removal curve of zero-valent iron. The two are compared, and the results are as follows image 3 shown. from image 3 It can be seen that the material prepared by the present invention has a higher removal rate than single zero-valent iron.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com