A kind of hydrothermal composite method of natural opal and tio2

A natural protein, hydrothermal technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. good, rich in resources, and excellent in visible light catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] a. Natural diatom opal raw ore is purified by flotation and sedimentation, then dried and ground. Weigh 1 g of diatom opal powder of 100 mesh, add 40 ml of titanium sulfate aqueous solution with a concentration of 0.3 mol / L, at this time the pH value of the system is maintained at about 2, and stir at room temperature for 30 hours.

[0026] b. The obtained slurry was placed in a closed reaction kettle lined with tetrafluoroethylene, and hydrothermally reacted in a thermostat at 180° C. for 0.5 hour. After cooling, NaOH solution with a concentration of 1 mol / L was added dropwise to adjust the pH of the system to 6, and stirred for 1 h.

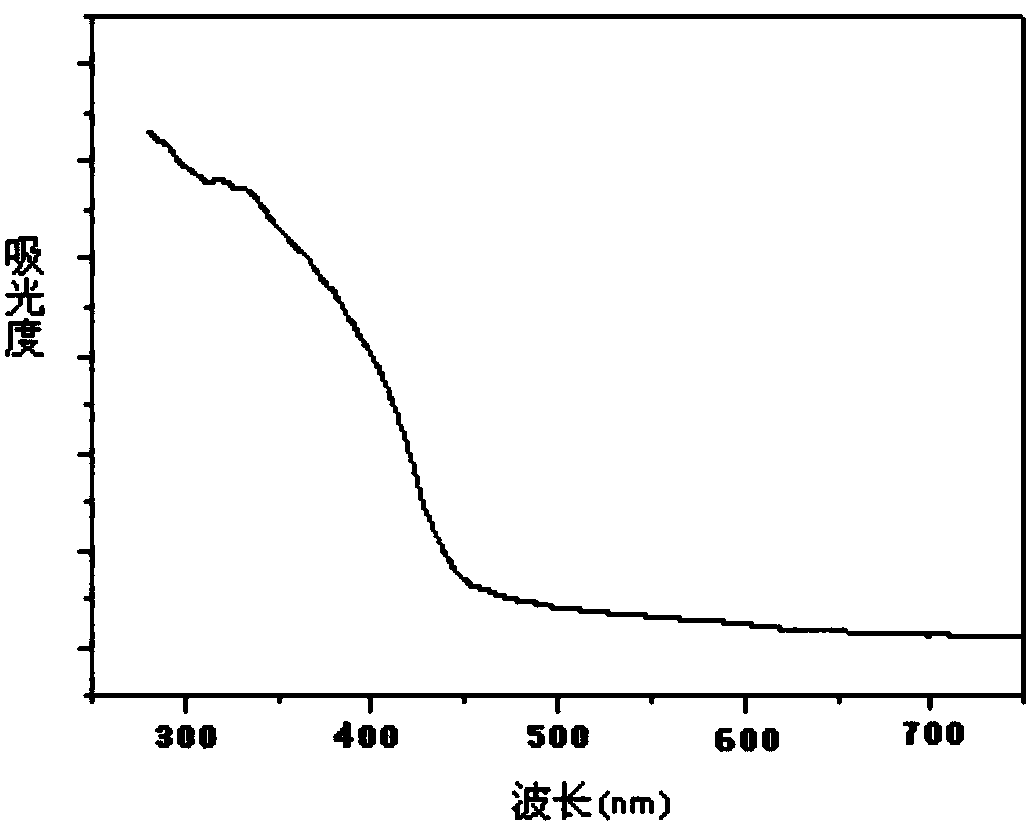

[0027] c. The obtained slurry was placed in a closed reaction kettle again, and hydrothermally reacted in a thermostat at 140° C. for 24 hours. Cooled slurry, centrifuged to no SO 4 2- , dried to get natural opal and TiO 2 composite photocatalyst. The spectral absorption threshold of the catalyst reaches 445nm, which has been extend...

Embodiment 2

[0029] a. The raw ore of natural opal shale in the Nenjiang River Basin is taken, purified by flotation and sedimentation, and then dried and ground. Weigh 0.5g of 100-mesh opal shale powder, add 5.2ml of titanium sulfate aqueous solution with a concentration of 1mol / L, mix well and add 5ml of water to the system. At this time, the pH value of the system is stable at about 1.6-2. Hour.

[0030] b. The obtained slurry was placed in a closed reaction kettle lined with tetrafluoroethylene, and hydrothermally reacted in a thermostat at 110° C. for 1 hour. After cooling, NaOH solution with a concentration of 0.2 mol / L was added dropwise to adjust the pH of the system to 5, and stirred for 1 h.

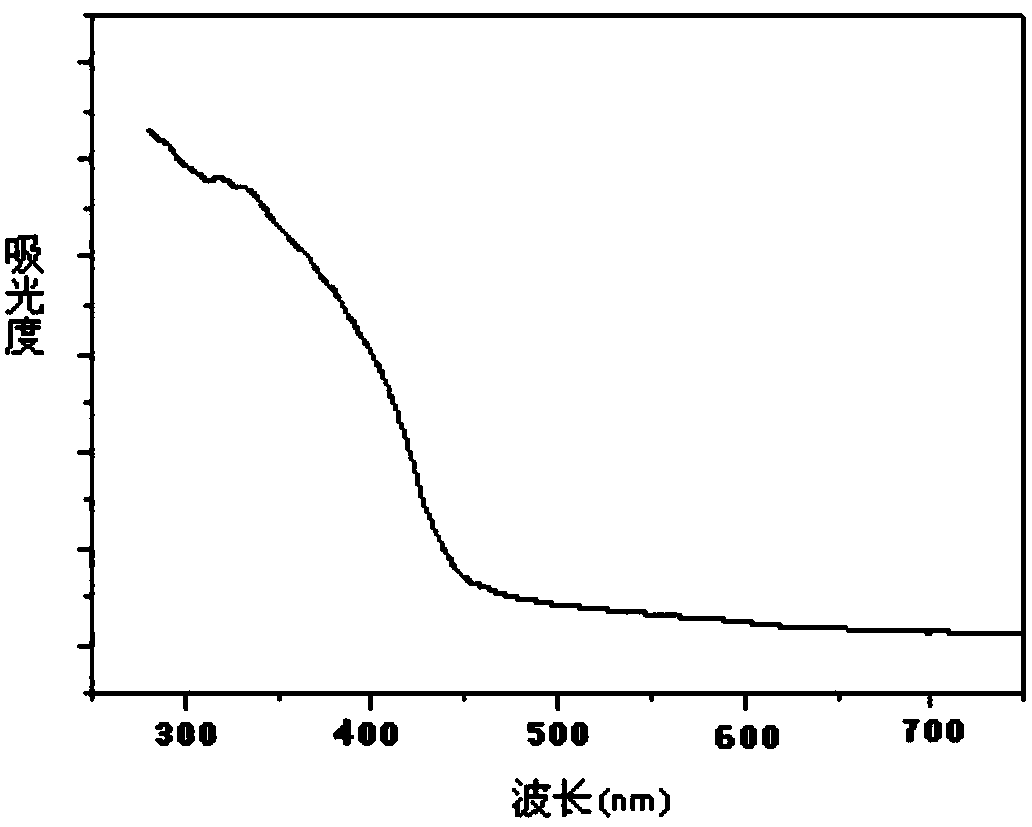

[0031] c. The obtained slurry was placed in a closed reaction kettle again, and hydrothermally reacted in a constant temperature box at 110° C. for 72 hours. Cooled slurry, centrifuged to no SO 4 2- , dried to get natural opal and TiO 2 composite photocatalyst. Under the irradiation o...

Embodiment 3

[0033] a. Natural diatom opal raw ore is purified by flotation and sedimentation, then dried and ground. Weigh 1 g of 200 mesh diatom opal powder, add 34.4 ml of titanium sulfate aqueous solution with a concentration of 0.2 mol / L, at this time the pH value of the system is maintained at about 2, and stir at room temperature for 30 hours.

[0034] b. The obtained slurry was placed in a closed reaction kettle lined with tetrafluoroethylene, and hydrothermally reacted in a thermostat at 160° C. for 0.5 hour. After cooling, NaOH solution with a concentration of 0.5 mol / L was added dropwise to adjust the pH of the system to 5, and stirred for 1 h.

[0035] c. The obtained slurry was placed in a closed reaction kettle again, and hydrothermally reacted in a thermostat at 160° C. for 12 hours. Cooled slurry, centrifuged to no SO 4 2- , dried to get natural opal and TiO 2 composite photocatalyst. Under the irradiation of visible light, the catalyst can decolorize 83% of the 20mg / L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com