Mold release film, method for manufacturing same, and method for manufacturing semiconductor package

A manufacturing method and release film technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as easy electrification, semiconductor chip damage, etc. , Difficult to curl the effect of mold compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

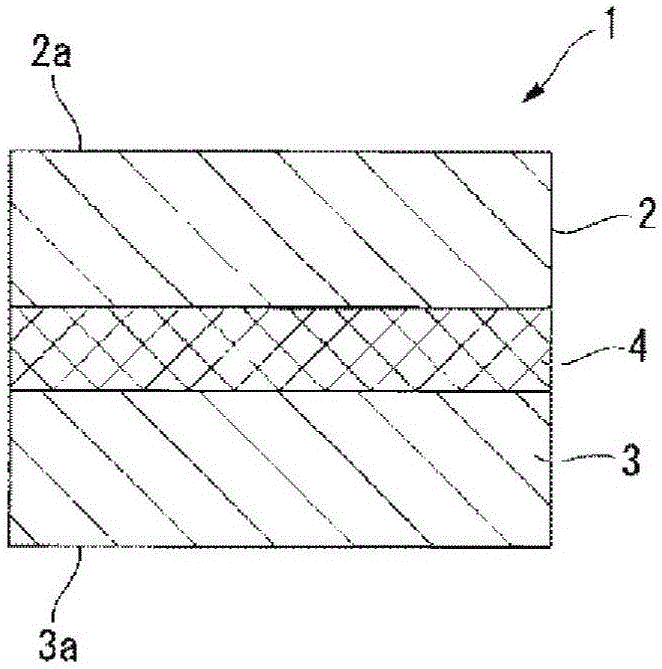

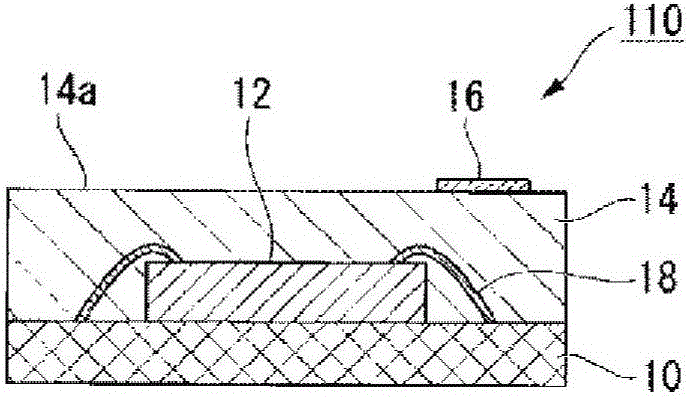

[0277] As an embodiment of the manufacturing method of a semiconductor package, it is directed to using the above-mentioned release film 1 as a release film and manufacturing it by compression molding. figure 2 The illustrated situation of the semiconductor package 110 is described in detail. The manufacturing method of the semiconductor package of this embodiment has the following process (α1)-(α7).

[0278] (α1) The release film 1 is arranged so that the release film 1 covers the cavity of the mold and the surface 2a of the release film 1 on the first thermoplastic resin layer 2 side faces the space in the cavity (the second thermoplastic resin layer 3 side The surface 3a faces the cavity surface) process.

[0279] (α2) A step of vacuum-adsorbing the release film 1 to the cavity surface side of the mold.

[0280] (α3) A step of filling the cavity with a curable resin.

[0281] (α4) Arranging the substrate 10 mounted with a plurality of semiconductor chips 12 at predeterm...

no. 2 Embodiment approach

[0321] As another embodiment of the manufacturing method of the semiconductor package, for using the above-mentioned release film 1 as the release film, it is manufactured by the transfer molding method. figure 2 The illustrated situation of the semiconductor package 110 is described in detail.

[0322] The manufacturing method of the semiconductor package of this embodiment has the following process (β1)-(β7).

[0323] (β1) The release film 1 is arranged so that the release film 1 covers the cavity of the mold and the surface 2a of the release film 1 on the first thermoplastic resin layer 2 side faces the space in the cavity (the second thermoplastic resin layer 3 side) The surface 3a faces the cavity surface) process.

[0324] (β2) A step of vacuum-adsorbing the release film 1 to the cavity surface side of the mold.

[0325] (β3) A step of disposing the substrate 10 on which the plurality of semiconductor chips 12 are mounted at predetermined positions in the cavity.

[...

no. 3 Embodiment approach

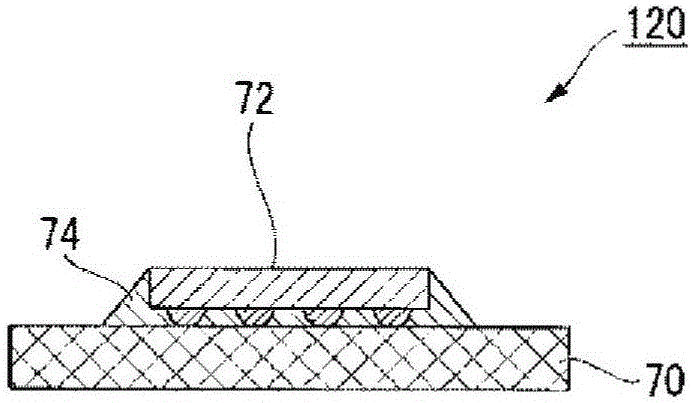

[0351] As another embodiment of the manufacturing method of the semiconductor package, for using the above-mentioned release film 1 as the release film, it is manufactured by the transfer molding method. image 3 The illustrated situation of the semiconductor package 120 is described in detail.

[0352] The manufacturing method of the semiconductor package of this embodiment has the following process (γ1)-(γ5).

[0353] (γ1) The release film 1 is arranged such that the release film 1 covers the cavity of the upper mold of a mold having an upper mold and a lower mold and the surface 2a of the release film 1 on the first thermoplastic resin layer 2 side faces the mold. The process of creating a space in the cavity (the surface 3a on the side of the second thermoplastic resin layer 3 faces the cavity surface of the upper mold).

[0354] (γ2) A step of vacuum-adsorbing the release film 1 to the cavity surface side of the upper mold.

[0355] (γ3) Arrange the substrate 70 on whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com