Optical filter and imaging device

An optical filter and wavelength technology, applied in chemical instruments and methods, optics, optical components, etc., can solve problems such as increased transmittance, increased visible light absorption, and failure to achieve high transmittance, excellent color reproducibility, Excellent blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0210] Next, the present invention will be further specifically described by way of examples. Example 1-1~Example 1~10, Example 2-1~Example 2~4, Example 3-1~Example 3~6 and Example 4-1~Example 4~10 are embodiments of the present invention, and other examples are comparative example.

[0211]

[0212] The dyes (A1-1) to (A1-26) used in Examples and the dyes (A2) to (A9) used in Comparative Examples were synthesized. The dyes (A1-1) to (A11-26) are dyes described in Tables 1 and 2 above, and the dyes (A2) to (A9) are dyes represented by formulas (A2) to (A9).

[0213]

[0214]

[0215] [Manufacture of pigment (A1-15)]

[0216] Hereinafter, a production example of the dye (A1-15) will be specifically described using the reaction formula (F1). In the following description, R in raw material components ((a), (g)) and intermediate products ((b) to (h)) 1 is isopropyl, R 2 is n-octyl (n-C 8 h 17 ), R 3 and R 4 for a hydrogen atom.

[0217] In the production of the d...

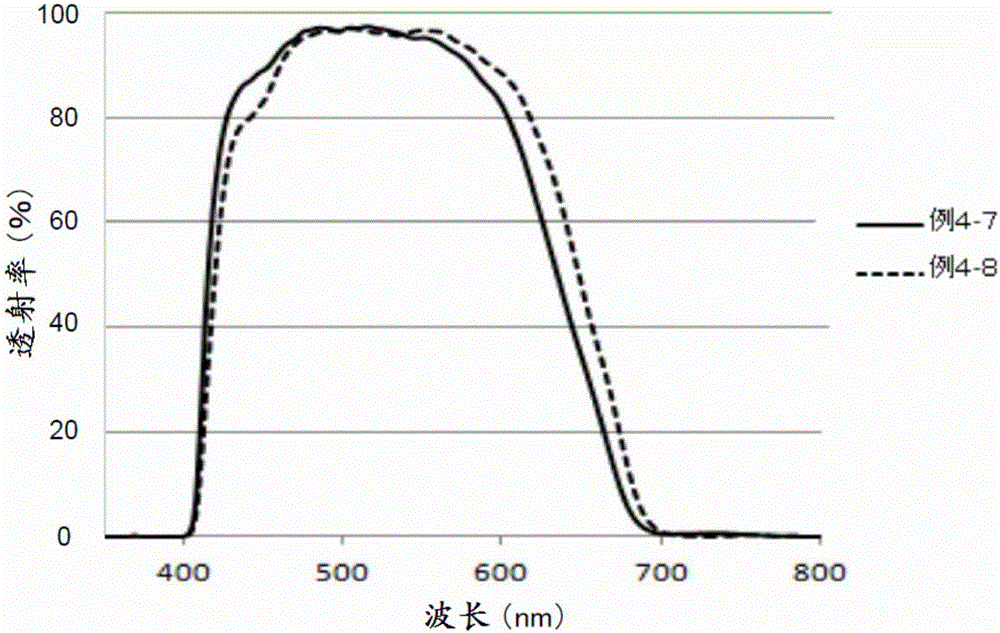

example 1-1~ example 1-14

[0281] The dyes shown in Table 5 were mixed with a 15% by mass cyclohexanone solution of a polyester resin (OKP850), and stirred and dissolved at room temperature to obtain a coating liquid. In addition, in Example 1-14, the dye A9 used was not dissolved in the resin solution, and the coating liquid could not be prepared. The obtained coating solution was applied on a glass (alkali-free glass; manufactured by Asahi Glass Co., Ltd., trade name: AN100) substrate with a thickness of 0.3 mm by spin coating, and dried by heating to form an absorption layer with a thickness of 0.9 to 1.0 μm. , to obtain NIR filters (Example 1-1 ~ Example 1-13).

example 2-1~ example 2-8

[0283] The dyes shown in Table 6 were mixed with a 15% by mass cyclohexanone solution of a cyclic olefin resin (manufactured by JSR Corporation, trade name: ARTON (registered trademark)), and stirred and dissolved at room temperature to obtain a coating. liquid. In addition, in Example 2-8, the dye A9 used was not dissolved in the resin solution, and the coating liquid could not be prepared. The obtained coating solution was coated on a glass (AN100) substrate with a thickness of 0.3 mm by spin coating, and heated and dried to form an absorption layer with a thickness of 0.9 to 1.0 μm to obtain a NIR filter (Example 2-1 to Example 2-7).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com