Method for quickly generating lamination flexible package lithium ion battery

A lithium-ion battery and formation method technology, which is applied in the field of rapid formation of laminated flexible packaging lithium-ion batteries, can solve the problems of poor battery consistency, long time required for formation, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

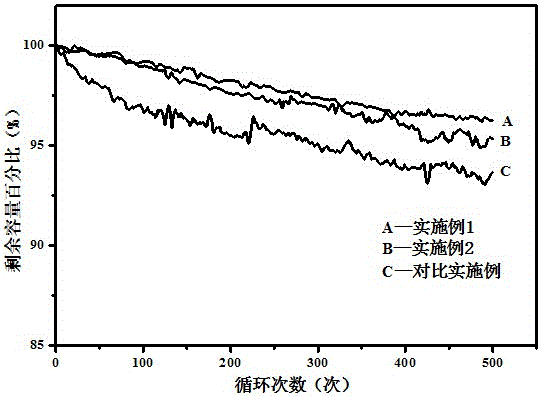

Embodiment 1

[0021] The type of battery used in this example is a laminated soft-packaged lithium-ion battery.

[0022] In the rapid chemical formation method described in this embodiment, the formation of a solid electrolyte phase boundary film (SEI film) comprises the following steps:

[0023] Step 1, pre-pressing: use high-temperature pressurization to form a jig, and pre-press the laminated flexible-packaged lithium-ion battery at a pressure of about 0.1MPa. At the same time, pre-heat to a temperature of 35°C, and keep the whole pre-pressing process for 20 minutes;

[0024] Step 2, Formation: After the pre-compression is completed, keep the pre-compression pressure and pre-heating temperature, and use 0.08C to charge the lithium battery with a constant current until the charging capacity reaches 12% of the reversible capacity of the battery.

[0025] The rapid chemical formation method described in this embodiment, the gas discharge stage, includes the following steps:

[0026] Step 1...

Embodiment 2

[0031] The type of battery used in this example is a laminated soft-packaged lithium-ion battery.

[0032] In the rapid chemical formation method described in this embodiment, the formation of a solid electrolyte phase boundary film (SEI film) comprises the following steps:

[0033] Step 1, pre-pressing: use high-temperature pressurization to form a jig, and pre-press the laminated flexible-packaged lithium-ion battery at a pressure of about 0.1MPa. At the same time, pre-heat to a temperature of 35°C, and keep the whole pre-pressing process for 20 minutes;

[0034] Step 2, formation: after the pre-compression is completed, maintain the pre-compression pressure and pre-heating temperature, and use 0.05C to charge the lithium battery with a constant current until the charging capacity reaches 8% of the reversible capacity of the battery.

[0035] The rapid chemical formation method described in this implementation example, the gas discharge stage, comprises the following steps: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com