Production and detection method of hardened bearing steel processing layer microstructure detection sample piece

A technology of microstructure and detection method, applied in the direction of material analysis using measurement of secondary emissions, measurement device, material analysis using wave/particle radiation, etc. problem, to achieve the effect of speeding up the grinding speed and improving the grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

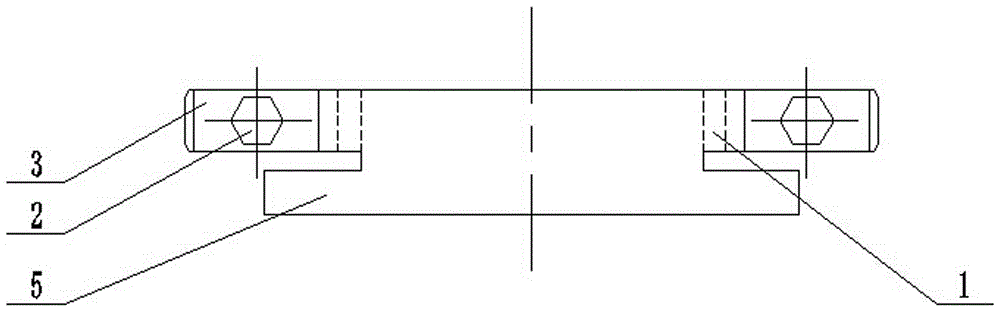

[0029] Specific implementation mode one: as figure 1 As shown, for the preparation and detection method of the microstructure detection sample of the hardened bearing steel processing layer, the method steps are as follows:

[0030] Step 1: Clamping and fixing the test sample 1; clamp and fix the test sample 1 with a special fixture (it can prevent chamfering on the edge of the test sample 1 when the test sample 1 is prepared), the test sample 1 is the ring part of hardened bearing steel;

[0031] In this embodiment, the outer ring of the deep groove ball bearing after hard turning is taken as the test sample 1, and the specifications of the test sample 1 are: the diameter of the outer circle is 43mm, the diameter of the inner circle is 38mm, and the width is 10mm.

[0032] Step 2: Rough grinding; the surface to be tested of the test sample 1 and the special fixture and the end face of the test surface on the same plane are used for rough grinding with a grinder, and then the...

specific Embodiment approach 2

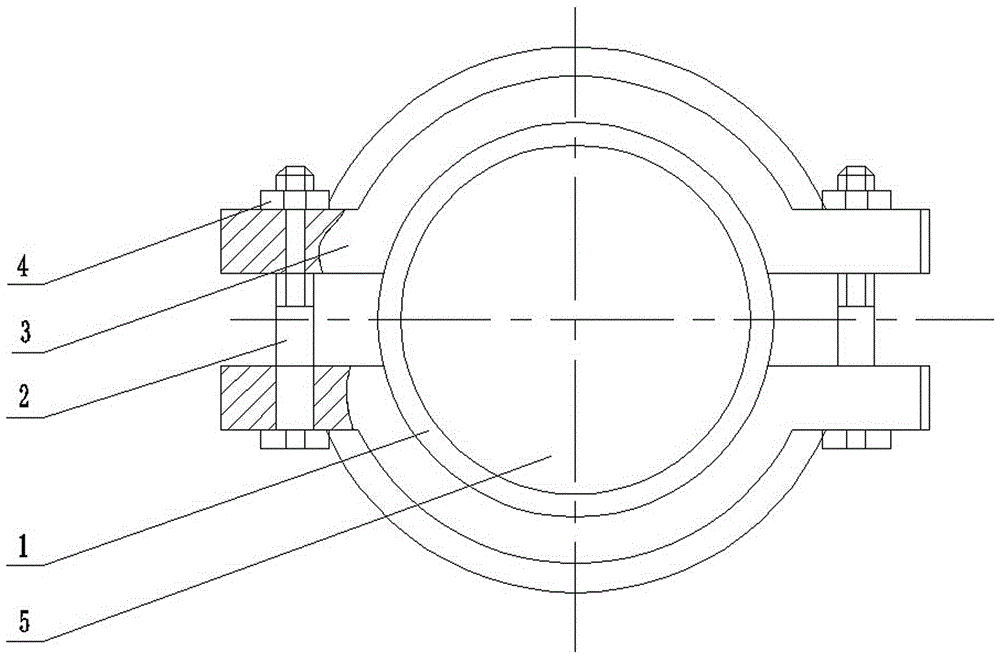

[0037] Specific implementation mode two: as Figure 2~Figure 4As shown in the specific embodiment 1, the sample preparation and detection method for the microstructure detection of the hardened bearing steel processing layer described in the first embodiment, in step 1; the special clamp includes a mandrel 5 and two semicircular clamp rings 3 , two bolts 2 and two nuts 4, each of the two ends of the semicircle-arc fixture ring 3 is provided with a fixed piece for the bolt 2 to pass through, and the two semicircle-arc fixture rings 3 are arranged opposite to form a circle Annular clamp ring, the mandrel 5 is made of coaxial and integral small-diameter cylinder and large-diameter cylinder, the small-diameter cylinder of the mandrel 5 is arranged in the circular clamp ring, The test sample 1 is set between the small-diameter cylinder of the mandrel 5 and the ring-shaped clamp ring, and the outer end surface of the test sample 1 and the ring-shaped clamp ring is located on the sam...

specific Embodiment approach 3

[0040] Specific implementation mode three: as figure 1 As shown in the specific embodiment 1, the sample preparation and detection method for the microstructure detection of the hardened bearing steel processing layer described in the first embodiment, in step 2; the surface to be detected of the detection sample 1 is roughly ground by a grinder, The grinding wheel adopts a white corundum flat grinding wheel with an abrasive grain size of 50#, the grinding speed is 380~420r / min, the feed is 0.03mm each time, and the cooling liquid is used for cooling during grinding (the grinding process can be regarded as low stress grinding , less damage to the original state of the sample surface).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com