Method for synchronous enriching and desalinating bovine serum albumins by using novel solid phase extractant

A technology of bovine serum albumin and solid-phase extraction agent, applied in the field of biochemical analysis and identification, can solve the problems of dialysis and electrodialysis, which are time-consuming, difficult to scale up large-scale production, and impossible to achieve separation, etc., to achieve easy industrial production, Low-cost and time-consuming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A kind of preparation method of graphene microsphere solid-phase extraction agent, concrete steps are:

[0023] Step 1: Add deionized water to graphene oxide, prepare a graphene oxide solution with a mass concentration of 3.0wt%, stir it under a magnetic stirrer for 8 hours, and then ultrasonicate it in an ultrasonic machine for 3 hours to obtain dispersed graphene oxide solution;

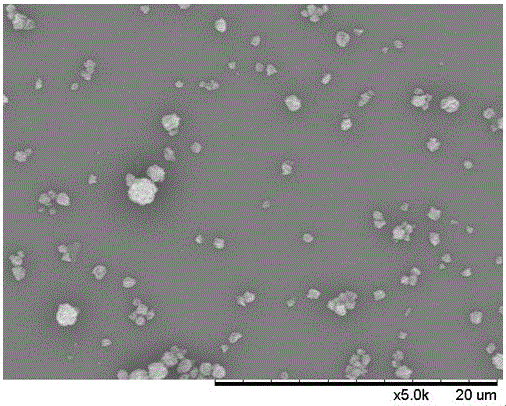

[0024] Step 2: Put the mixed solution in an ultrasonic nebulizer connected with a quartz tube, and the ultrasonic frequency is 1.5MHz. Make it atomized into aerosol droplets, in N 2 Driven by a vacuum pump and a suction filter, it slowly passes through a quartz tube heated to 550°C, and the end is collected with a PTFE filter membrane. Dry at room temperature for 3 hours, then put it in a vacuum desiccator and dry at 60°C for 12 hours to obtain a graphene microsphere solid-phase extraction agent with a particle size of 1 μm-2 μm, such as figure 1 shown.

Embodiment 2

[0026] Carry out compression resistance experiment with the graphene microsphere gained in embodiment 1, concrete steps are:

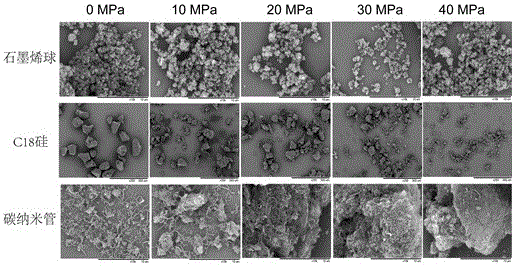

[0027] Three kinds of adsorbents were selected as graphene microspheres, C18 silicon and carbon nanotubes, four pressures of 10 MPa, 20 MPa, 30 MPa and 40 MPa were set, and the pressure action time was 3 minutes. A pressure test is carried out on a material, and the material under pressure is immediately observed under a scanning electron microscope. It was found that the graphene microspheres still maintained their original appearance under the four pressure environments, and their structure did not change, indicating that the compression resistance was strong; C18 silicon had a small amount of fragmentation under the condition of 10 MPa, and as the pressure increased, the fragmentation The degree of carbon nanotubes gradually intensifies. When the pressure is 40 MPa, they are all in powder form, and the compression resistance is poor. Flaky, loses i...

Embodiment 3

[0029] Using the graphene microspheres obtained in Example 1 as a solid-phase extractant for enrichment and desalination of bovine serum albumin, the specific steps are:

[0030] Step 1: Weigh 20 mg of graphene microspheres and add them to a solid-phase extraction column with a volume of 3 ml, seal the upper and lower sieve plates, and activate the column with 10 ml of methanol solution with a volume percentage of 70%, and control the flow rate to 1.2ml / min;

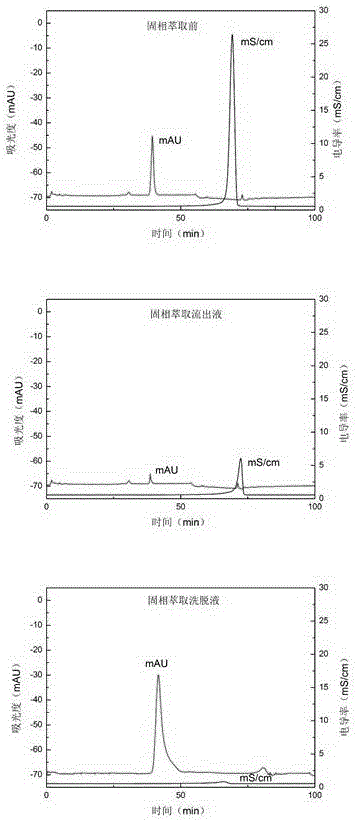

[0031] Step 2: Add sodium chloride with a mass ratio of 5% to the bovine serum albumin solution, use a constant-flow pump to pass the salt-containing protein solution through the solid-phase extraction column, control the flow rate to 1.2ml / min, and add 3ml volume after loading the sample Rinse with 10% methanol solution to remove unadsorbed protein, and vacuum to dryness. Use 2ml of acetonitrile as the protein eluent, control the flow rate to 0.2ml / min, and collect the eluate. Select non-solid-phase extraction soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com