A kind of lace fabric with metallic luster and preparation method thereof

A metallic luster and lace technology, which is applied in the field of textile materials, can solve the problems affecting the skin-friendly performance and pattern of lace fabrics, and achieve the effects of excellent antibacterial performance, improved metallic texture, and excellent skin-friendly properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

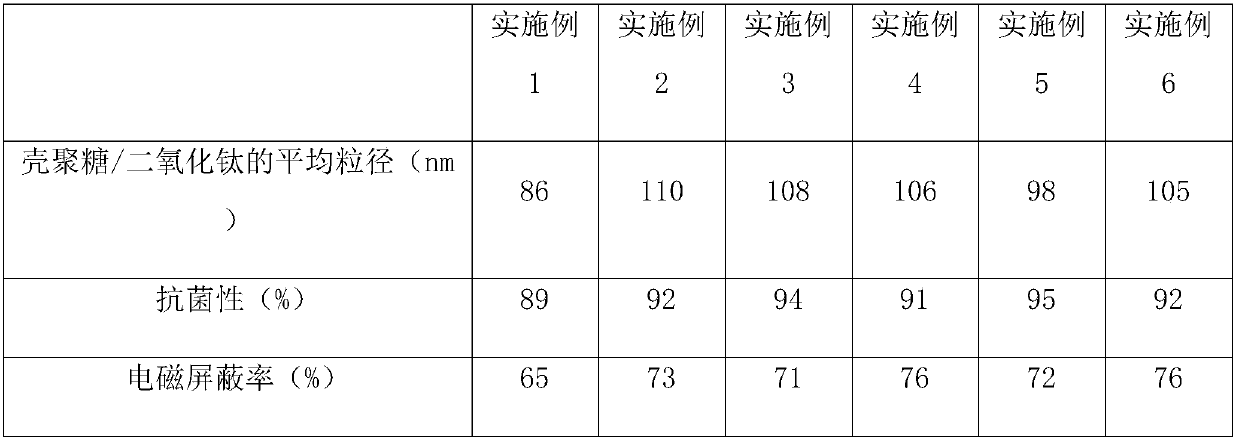

Examples

Embodiment 1

[0027] (1) Chitosan with a degree of deacetylation of 75% is dissolved in 15% citric acid aqueous solution with a solid-liquid ratio of 1g:15ml, fully stirred until all dissolve to form a chitosan solution. Add 0.5 g of nano-titanium dioxide particles with a particle size of 20 nm to 20 ml of chitosan solution, ultrasonically disperse for 15 minutes, add 2 g of glutaraldehyde crosslinking agent, and heat and stir at 50° C. for 30 minutes to obtain a chitosan / titanium dioxide solution.

[0028] (2) prepare base layer with silk fiber and silver fiber as raw material, nylon, spandex and silver fiber prepare decorative layer as raw material, obtain lace gray cloth, wherein the content of metal fiber is 15%, the content of silk fiber is 10%, the content of spandex 5% and the rest is nylon.

[0029] (3) The lace fabric prepared in step (2) is immersed in the chitosan / titanium dioxide solution prepared in step (1) with a bath ratio of 1:30, 2 Under the intensity of ultraviolet radia...

Embodiment 2

[0031] (1) Chitosan with a degree of deacetylation of 90% is dissolved in 20% citric acid aqueous solution with a solid-liquid ratio of 1g:30ml, and fully stirred until all dissolve to form a chitosan solution. Add 1 g of nano-titanium dioxide particles with a particle size of 50 nm to 30 ml of chitosan solution, ultrasonically disperse for 15 minutes, add 5 g of glutaraldehyde cross-linking agent, and heat and stir at 60° C. for 60 minutes to obtain a chitosan / titanium dioxide solution.

[0032] (2) prepare base layer with silk fiber and silver-plated fiber as raw material, nylon, spandex and silver-plated fiber prepare decorative layer as raw material, obtain lace gray cloth, wherein the content of metal fiber is 30%, the content of silk fiber is 25%, spandex The content is 15%, and the rest is nylon.

[0033] (3) The lace gray cloth prepared in step (2) is soaked in the chitosan / titanium dioxide solution prepared in step (1) with a bath ratio of 1:50, at 100 μW / cm 2 Under ...

Embodiment 3

[0035] (1) Chitosan with a degree of deacetylation of 80% is dissolved in 17% citric acid aqueous solution with a solid-liquid ratio of 1g:20ml, and fully stirred to form a chitosan solution after fully dissolving. Add 0.7 g of nano-titanium dioxide particles with a particle size of 35 nm to 25 ml of chitosan solution, ultrasonically disperse for 15 minutes, add 3 g of glutaraldehyde cross-linking agent, and heat and stir at 55° C. for 40 minutes to obtain a chitosan / titanium dioxide solution.

[0036] (2) prepare base layer with silk fiber and gold-plated fiber as raw material, nylon, spandex and gold-plated fiber prepare decorative layer as raw material, obtain lace gray cloth, wherein the content of metal fiber is 25%, the content of silk fiber is 15%, the content of spandex 8% and the rest is nylon.

[0037] (3) The lace fabric prepared in step (2) is immersed in the chitosan / titanium dioxide solution prepared in step (1) with a bath ratio of 1:35, 2 Under the intensity o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com