Production method of single-cake 576f super-multihole POY (pre-oriented yarn)

A production method and polyester filament technology are applied in the field of single-cake 576f ultra-porous POY polyester filaments, which can solve the problems of unattainable product quality, low machine efficiency and high production cost, and improve production efficiency and reduce production costs. , reduce the effect of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

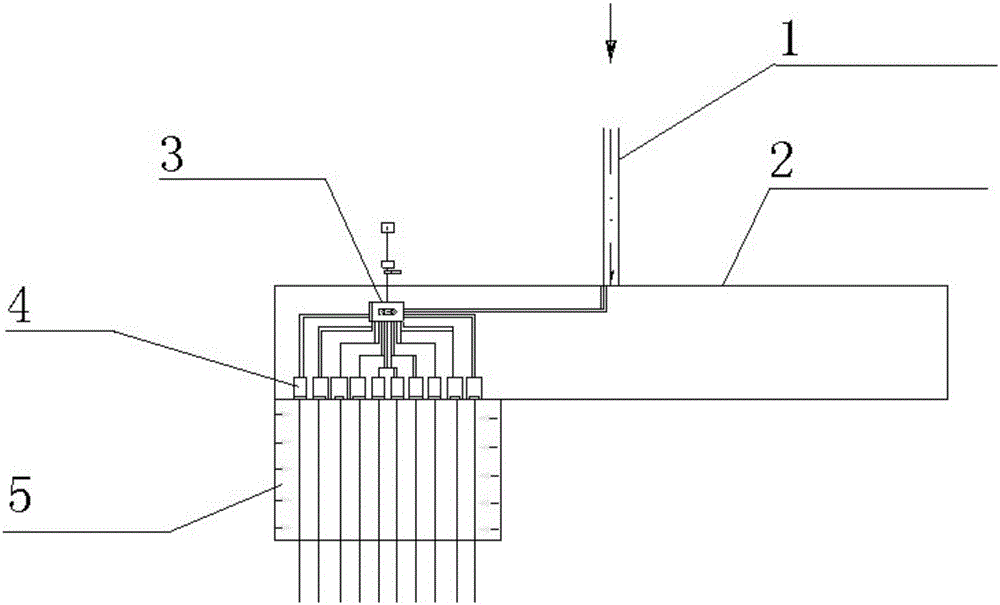

[0025] refer to figure 1 and figure 2 , the production method of single cake 576f ultra-porous POY polyester filament, is characterized in that: described production method comprises the steps:

[0026] S1. Using semi-glossy polyester melt as raw material, first pressurize the semi-glossy polyester melt to 150-200Pa through the melt delivery pipeline through the booster pump, and then send it to the melt cooler. After the light polyester melt is cooled to 275°C-278°C, it is sent into the spinning box;

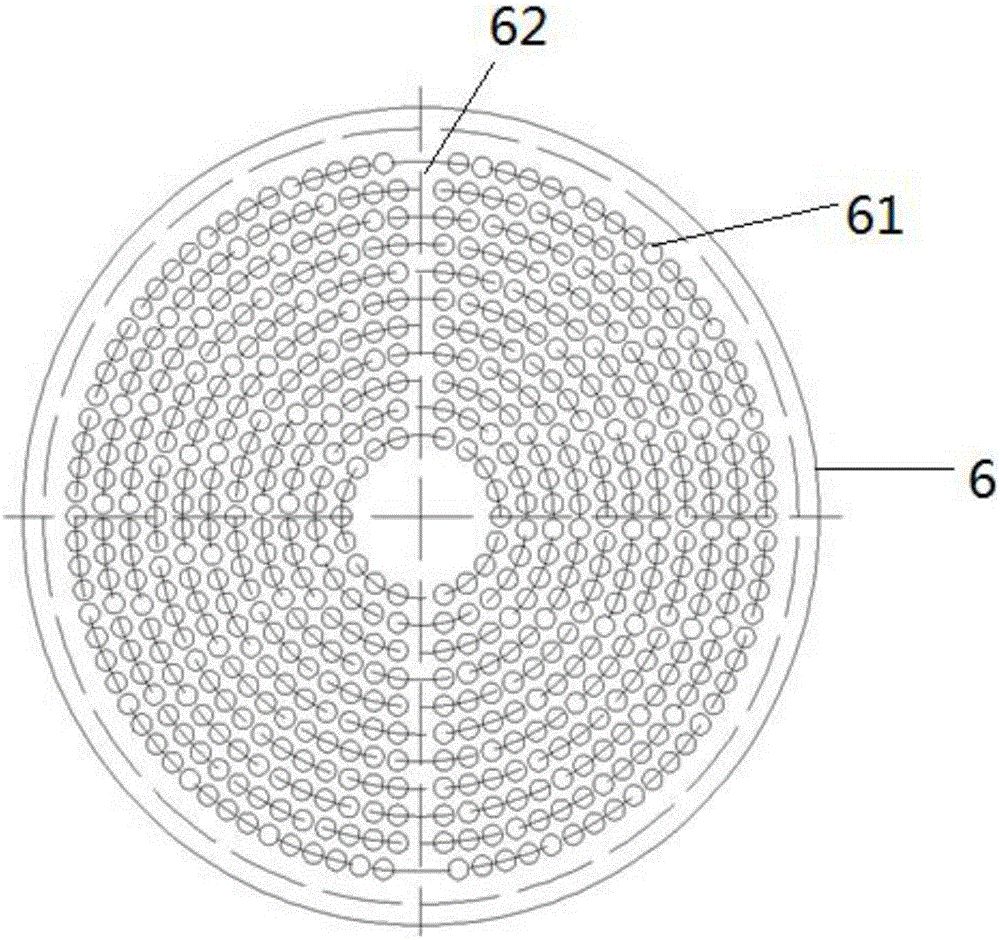

[0027] S2. The melt after entering the spinning box is metered by the metering pump, and then transported to the spinning assembly in the spinning box through a thin pipe, filtered, extruded through the spinneret, and then cooled and solidified by the ring blowing device to form primary fibers;

[0028] S3. The nascent fibers in step S2 are oiled sequentially through double-channel oil nozzles, and the network device increases the cohesion, and then the winding tension is co...

Embodiment 2

[0041] In this embodiment, the conveying temperature of the semi-gloss polyester melt in the conveying pipe is 279° C., and the other implementation methods are the same as those in Embodiment 1.

[0042] The 576f ultra-porous POY polyester filament produced by the present embodiment has main technical indicators: the strength is 2.55cn / dtex, the elongation at break is 126%, and the evenness unevenness (CV% value) is 0.96%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com