Preparation method for synchronous-grown wafer-level AB-stack double-layer graphene and equipment for preparation method

A double-layer graphene stacking technology, applied in the field of graphene, can solve the problems of low mobility, complex time-consuming process, and many defects in double-layer graphene, and achieve the effect of simple operation and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

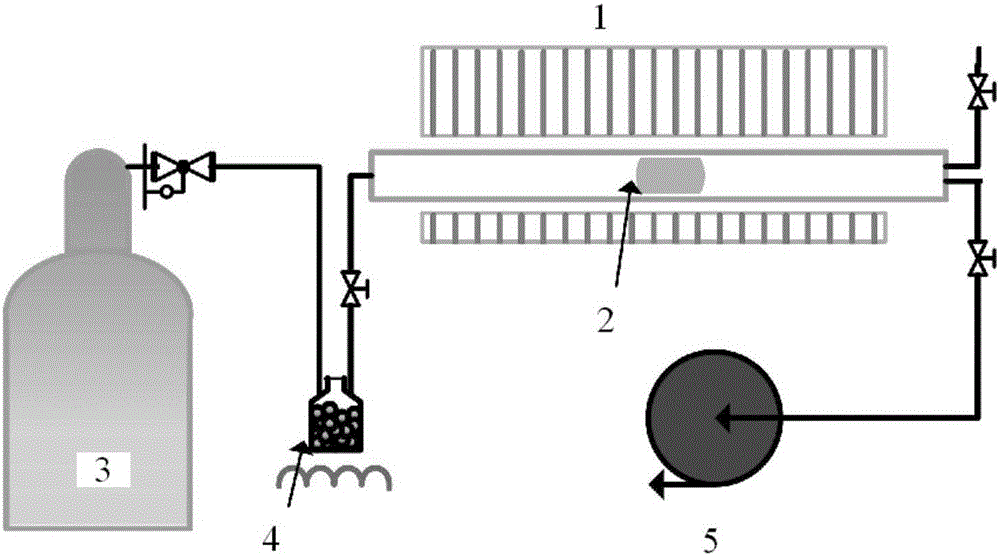

[0034] like figure 1 As shown, a copper foil 2 is provided in the reactor 1, and at the same time, an inert carrier gas 3 containing a high hydrogen partial pressure is passed through the reactor 1, and the inlet end of the reactor is connected to a solid or liquid carbon source device 4; The copper foil 2 is provided with a heating device. 5 is a mechanical pump among the figure.

[0035] The following is an example of a solid carbon source.

[0036] ⑴. Select copper foil (Alfa Aesar, 99.8% purity, 25 μm thickness), cut it into a size of 10cm*10cm (the size of copper foil is completely determined by the size of the reaction chamber), soak it in acetic acid solution for 10 hours, and blow it with nitrogen After drying, roll it into a roll and put it into the reaction chamber;

[0037] ⑵. Hydrocarbons are made of polystyrene (Mw: 25000) and placed in a quartz vessel at one end of the gas source;

[0038] ⑶. Inject 10% H 2 / Ar mixed gas, flow 400sccm, to figure 2The heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com