A kind of preparation method of double hydroxyl metal oxide sealing film layer on the surface of magnesium alloy

A technology of double hydroxyl metal and magnesium alloy, applied in anodizing and other directions, can solve the problems of complex preparation process of LDH film and insufficient research, and achieve the effects of compact and uniform size, convenient operation and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

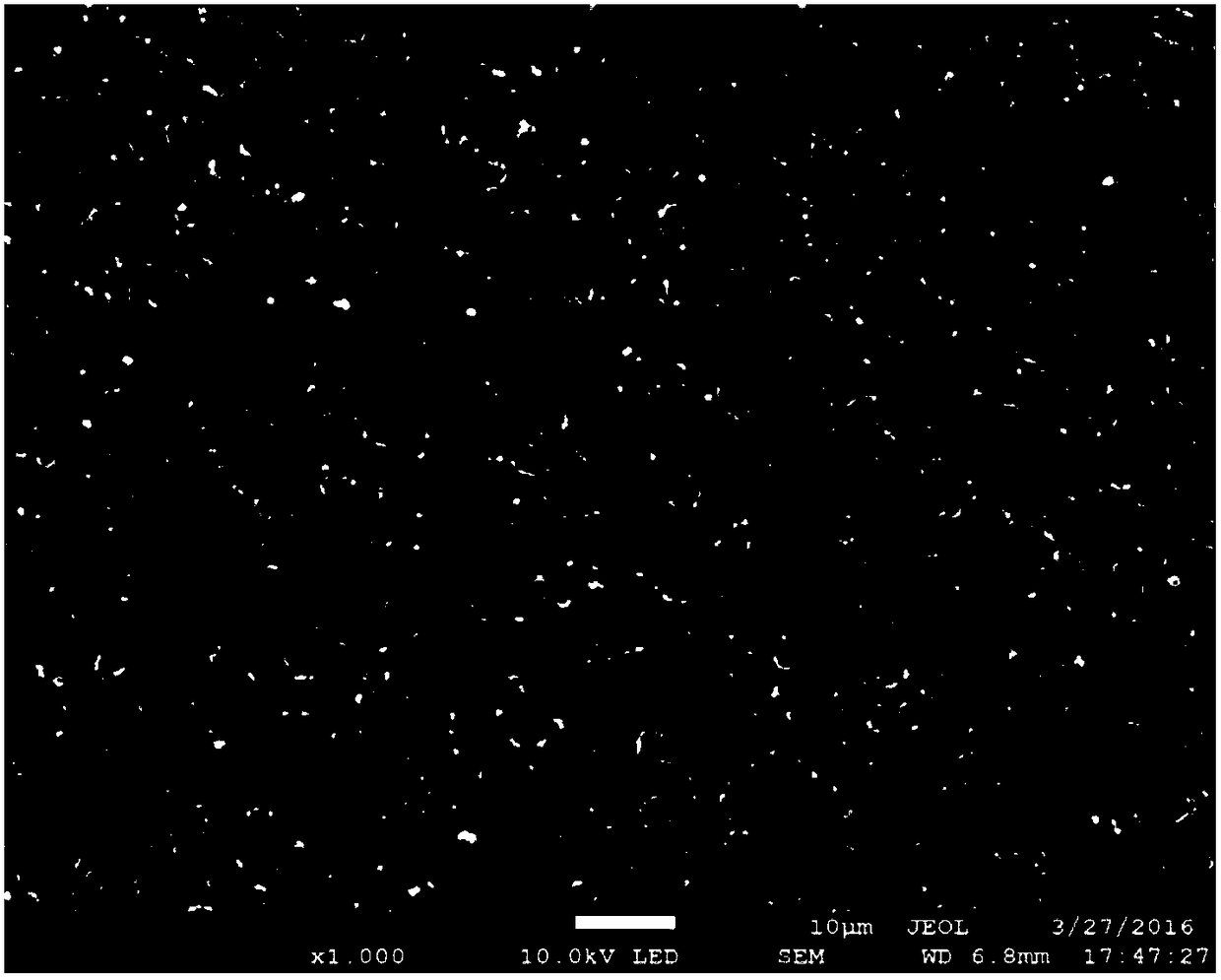

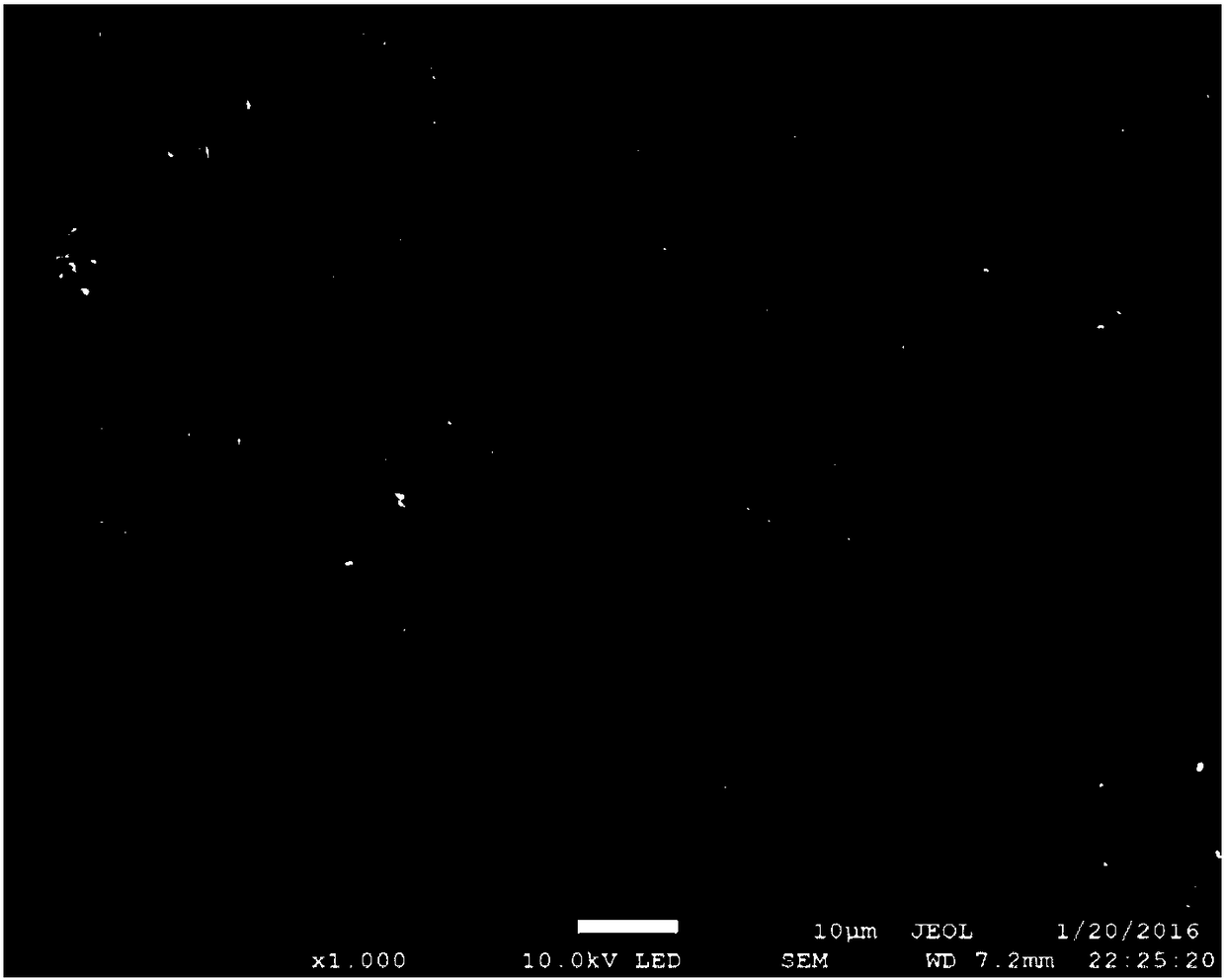

Image

Examples

Embodiment 1

[0040] 1. Configure in situ growth solution

[0041] An in-situ growth solution of 0.05M aluminum nitrate and 0.3M ammonium nitrate was prepared, and then the pH value of the in-situ growth solution was adjusted to 10.72 with dilute ammonia water, and the temperature of the solution was adjusted to 20°C.

[0042] 2. In situ growth

[0043] The steps to carry out the AZ31 magnesium alloy substrate in sequence are: anodic oxidation step 1 of alkaline anodic oxidation solution system → flowing cold deionized water cleaning step 2 → in-situ growth solution preparation step 3 (preparing a certain pH value concentration of 0.05M, Use the PHS-3C experimental pH meter to adjust the pH value so that the pH value of the aluminum nitrate solution added with ammonium nitrate reaches 10.72) → sample cleaning step 4 (before the sample is placed in the JP-020 Jiemeng brand ultrasonic Cleaning in the cleaning machine for 5 minutes) → in-situ growth step 5 (put the high-pressure reaction kettle...

Embodiment 2

[0052] 1. Configure in situ growth solution

[0053] An in-situ growth solution of 0.05M aluminum nitrate and 0.3M ammonium nitrate was prepared, and then the pH value of the in-situ growth solution was adjusted to 12.04 with dilute ammonia water, and the temperature of the solution was adjusted to 10°C.

[0054] 2. In situ growth

[0055] The steps to carry out the AZ31 magnesium alloy substrate in sequence are: anodic oxidation step 1 of alkaline anodic oxidation solution system → flowing cold deionized water cleaning step 2 → in-situ growth solution preparation step 3 (preparing a certain pH value concentration of 0.05M, Use the PHS-3C experimental pH meter to adjust the pH value so that the pH value of the aluminum nitrate solution added with ammonium nitrate reaches 12.04) → sample cleaning step 4 (before the sample is placed in the JP-020 Jiemeng brand ultrasonic Cleaning in a washing machine for 5 minutes) → in-situ growth step 5 (put the high-pressure reaction kettle ...

Embodiment 3

[0059] 1. Configure in situ growth solution

[0060] An in-situ growth solution of 0.05M aluminum nitrate and 0.3M ammonium nitrate was prepared, and then the pH value of the in-situ growth solution was adjusted to 10.72 with dilute ammonia water, and the adjusted temperature was 30°C.

[0061] 2. In situ growth

[0062] The steps to carry out the AZ31 magnesium alloy substrate in sequence are: anodic oxidation step 1 of alkaline anodic oxidation solution system → flowing cold deionized water cleaning step 2 → in-situ growth solution preparation step 3 (preparing a certain pH value concentration of 0.05M, Use the PHS‐3C experimental pH meter to adjust the pH value so that the pH value of the aluminum nitrate solution added with ammonium nitrate reaches 10.72) → sample cleaning step 4 (before the sample is placed in the JP‐020 Jiemeng brand ultrasonic Cleaning in the cleaning machine for 5 minutes) → in-situ growth step 5 (put the high-pressure reaction kettle with the anodize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com