Elastic trash bag and method of making the same

a trash bag and plastic technology, applied in the field can solve the problems of affecting the quality of plastic trash bags, etc., and achieve the effect of easy incorporation and easy incorporation into trash bags

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

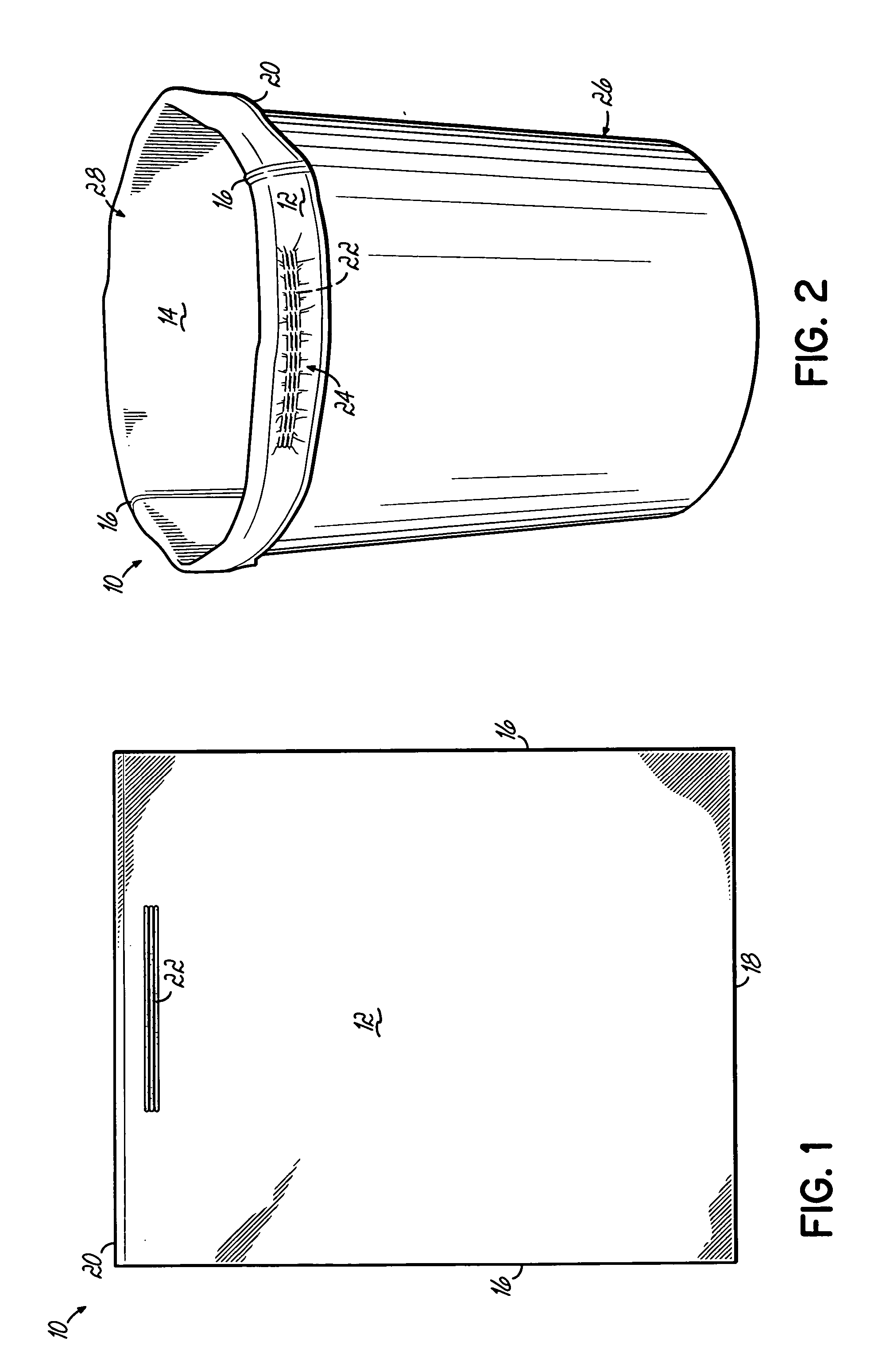

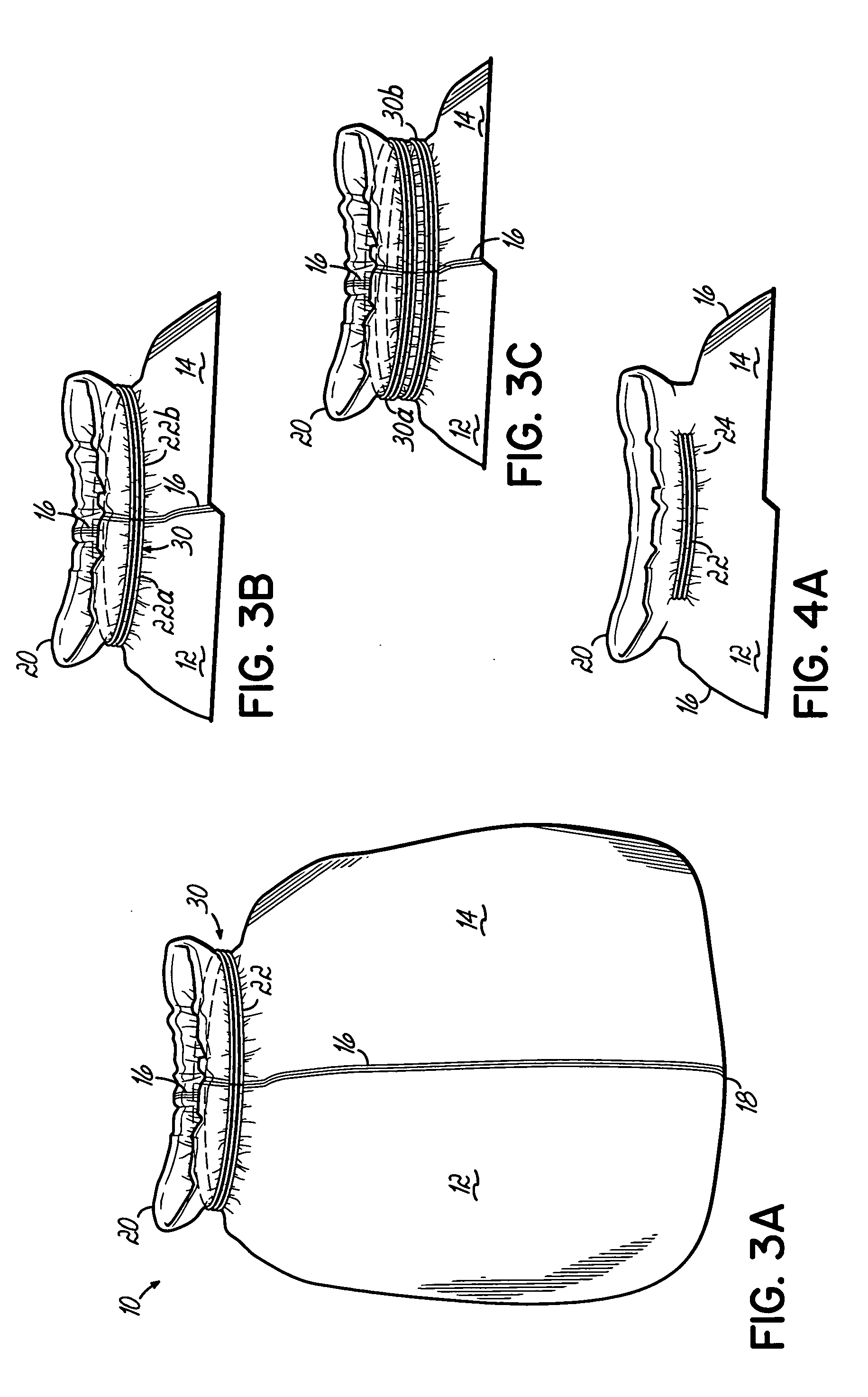

[0038] Referring to FIG. 1, an elastic trash bag 10 is schematically illustrated in accordance with one embodiment of the present invention and comprises a trash bag body having two panels of plastic 12 and 14 (FIG. 2) that are sealed along two vertical sides 16 and along the bottom side 18 of the two panels 12 and 14. The top side of the panels 12 and 14 is not sealed and thereby provides an opening or mouth 20 for access into the interior of the bag. It will be appreciated that other formations of the trash bag 10 known to those skilled in the art are possible as well.

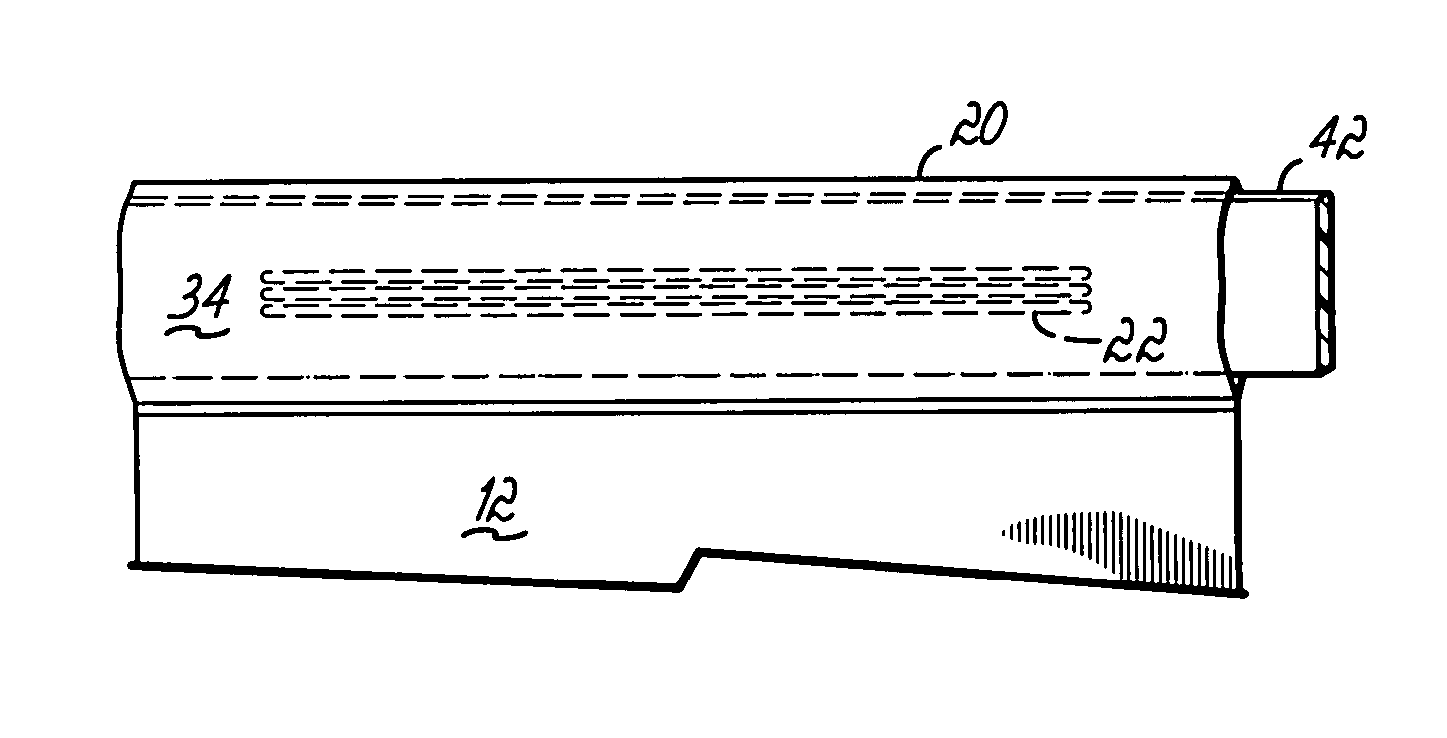

[0039] In one embodiment of the present invention, multiple elastic strand segments 22 are adhesively attached to the trash bag 10 and extend generally parallel to the bag mouth 20 and are positioned relatively close to the bag mouth. The elastic strands 22 are attached to at least one of the plastic panels 12 and 14 while the strands 22 are stretched or elongated. In accordance with one embodiment, the adhesive may...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com