A graphite-containing high-speed steel roll

A high-speed steel and graphite technology, applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problems of affecting the surface quality of the rolled material, increase the friction coefficient of the roll, and the linear velocity difference, so as to improve the comprehensive performance and improve the Rolled product surface quality, the effect of reducing the roughness level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

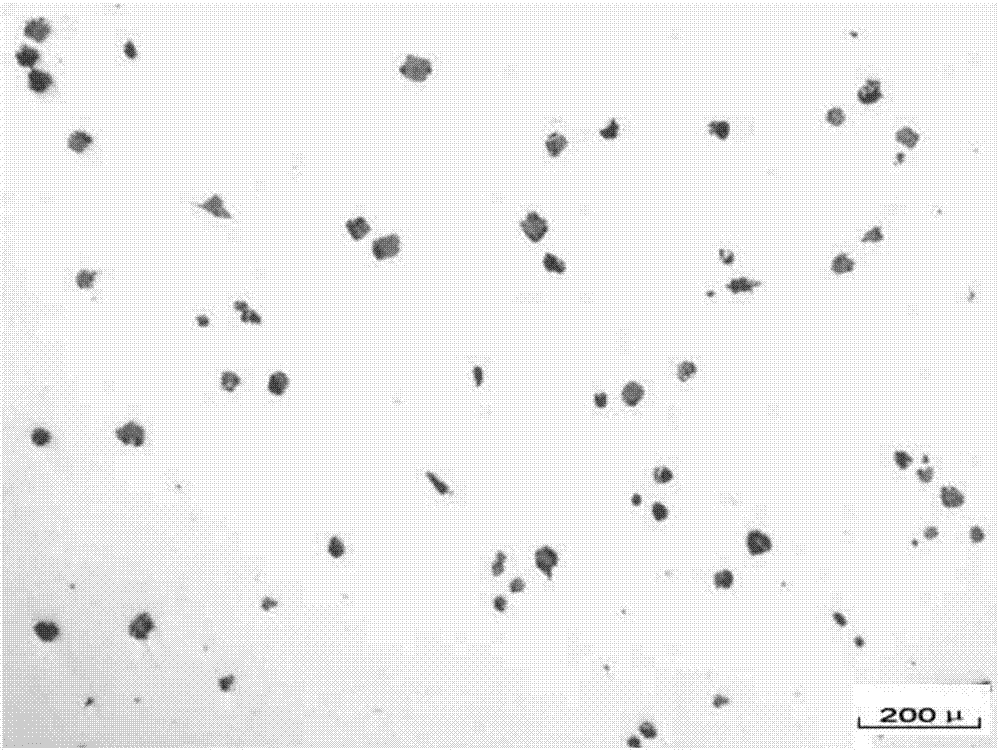

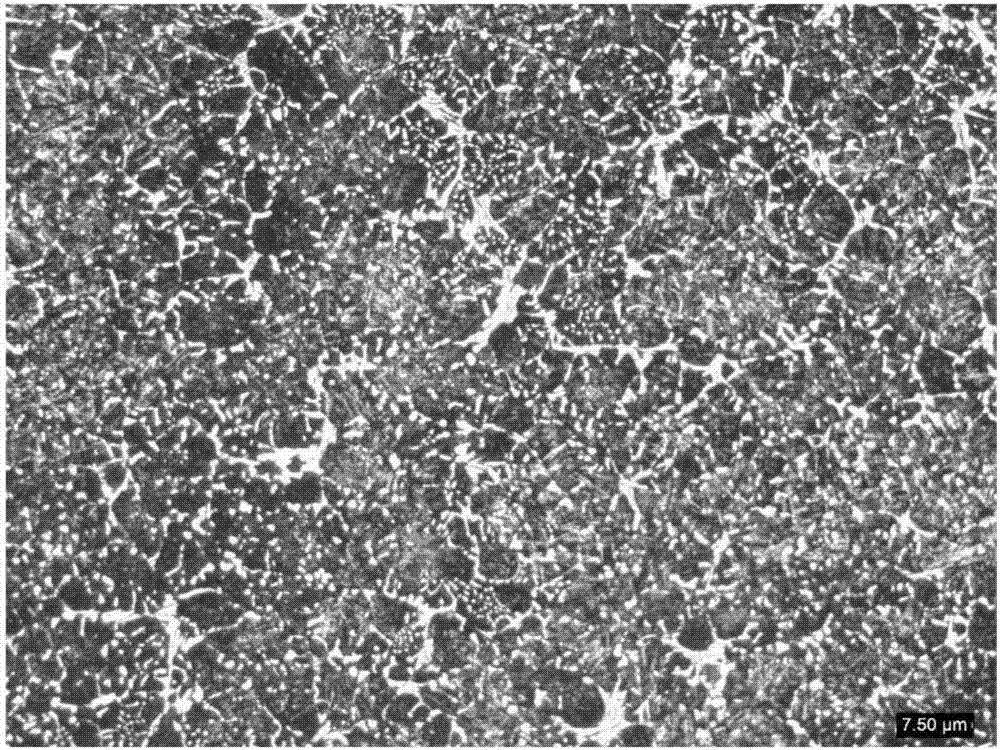

[0035] Embodiment 1 A kind of manufacturing method of the outer shell (working layer) of the centrifugal high-speed steel roll that contains graphite

[0036] 1) The chemical composition of the outer layer is composed by mass fraction (%): C 2.0-3.0%, Si 0.8-2.5%, Mn 0.2-1.0%, 0<P≤0.05%, 0<S≤0.02%, Cr 3-10 %, Ni 0.5-3.5%, Mo 2.5-6.0%, V 3-8%, 0<W≤10%, 0<B≤0.5%, N 60-500PPM, prepare the charge;

[0037] 2) Using intermediate frequency furnace for smelting;

[0038] 3) Si content before furnace control = Si content of finished product - 0.35%; V content before furnace control = V content of finished product - 0.25%;

[0039] 4) Measure the liquid and solidus temperature (T L , T S );

[0040] 5) Control the furnace temperature T 出 = liquidus temperature of the outer metal liquid (T L外 )+(240~300)℃;

[0041] 6) Metamorphic treatment of carbon, nitrogen and borides out of the furnace:

[0042] During the furnace discharge process, along with the metal flow, vanadium alloy ...

Embodiment 2

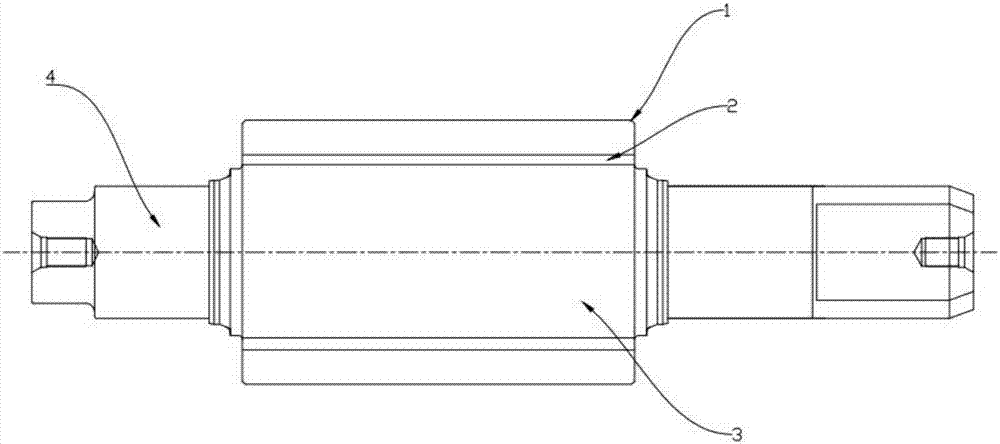

[0059] Embodiment 2 A kind of manufacturing method of graphite-containing high-speed steel centrifugal nodular cast iron mandrel composite roll

[0060] Then the 10) step of above-mentioned embodiment 1, when intermediate layer metal solidification end temperature=intermediate layer metal liquid is supercooled 80~200 ℃ under solidus temperature, promptly T S中-(80~200)℃, the centrifuge stops; the outer cylinder with the middle layer and the mold of the cylinder are combined with the pre-prepared lower roll neck box, upper roll neck box, center injection pipe, etc. Carry out box assembly; then pour in the prepared high-strength nodular cast iron metal liquid containing carbon C2.5-3.5%; control the pouring temperature of the nodular cast iron metal liquid, and it should meet the requirement that the middle layer metal liquid is overheated at the liquidus temperature 10-50 degrees, namely T L中 +(10~50)℃, and at the same time, it should satisfy ≥ 50~100 degrees of superheat on th...

Embodiment 3

[0064] Embodiment 3 A kind of manufacturing method of graphite-containing high-speed steel centrifugal steel core composite roll

[0065] Following the step 10) of Example 1, the middle layer is made of semi-steel containing carbon C1.2-2.5%.

[0066] 11) The material of the roller core filling metal liquid is carbon-containing C1.2-2.5% graphite steel material, and the core metal liquid is made of a semi-metallic type (sand in the inner cavity of the metal type, and the thickness of the sand is 15-20mm) in the lower box. The inner cavity of the middle metal mold (including the poured outer cylinder), the upper roller neck sand mold, and the upper surface of the thermal insulation riser are 300-600mm lower, stop the core pouring, and then add 50-100mm thick thermal insulation agent to the surface of the molten metal in the riser, Stop core.

[0067] Replace the high-temperature core-filling molten metal in the same furnace and make some riser preparations. It is required to e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com