Rare earth aluminum-magnesium alloy tire mold casting material and manufacturing method thereof

A tire mold and aluminum-magnesium alloy technology, which is applied in the field of rare earth aluminum-magnesium alloy casting materials, can solve the problems of difficult to improve mechanical properties and mechanical properties, difficult to control quality problems, large mold loss, etc., so as to shorten the vulcanization time and the accuracy retention time. long, energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

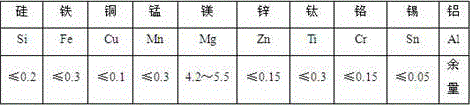

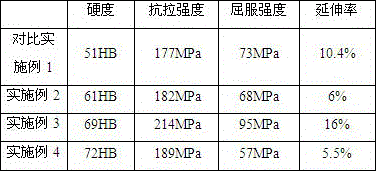

[0051] Example 2 A rare earth aluminum-magnesium alloy tire mold casting material

[0052] The chemical composition of raw material is the same as comparative example 1, only changes the proportioning of each raw material, changes into:

[0053] The mold casting material comprises the following raw materials:

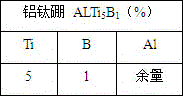

[0054] Aluminum-magnesium alloy 200kg, aluminum-manganese alloy 50g, rare earth alloy 30g, aluminum-titanium-boron 200g, slag removal agent (covering agent) 260g.

Embodiment 3

[0055] Example 3 A rare earth aluminum-magnesium alloy tire mold casting material

[0056] The chemical composition of raw material is the same as comparative example 1, only changes the proportioning of each raw material, changes into:

[0057] The mold casting material comprises the following raw materials:

[0058] Aluminum-magnesium alloy 200kg, aluminum-manganese alloy 100g, rare earth alloy 60g, aluminum-titanium-boron 200g, slag removal agent (covering agent) 260g.

Embodiment 4

[0059] Example 4 A rare earth aluminum-magnesium alloy tire mold casting material

[0060] The chemical composition of raw material is the same as comparative example 1, only changes the proportioning of each raw material, changes into:

[0061] The mold casting material comprises the following raw materials:

[0062] Aluminum-magnesium alloy 200kg, aluminum-manganese alloy 150g, rare earth alloy 100g, aluminum-titanium-boron 200g, slag removal agent (covering agent) 260g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com