A kind of compound antibacterial coating material, preparation method and application thereof

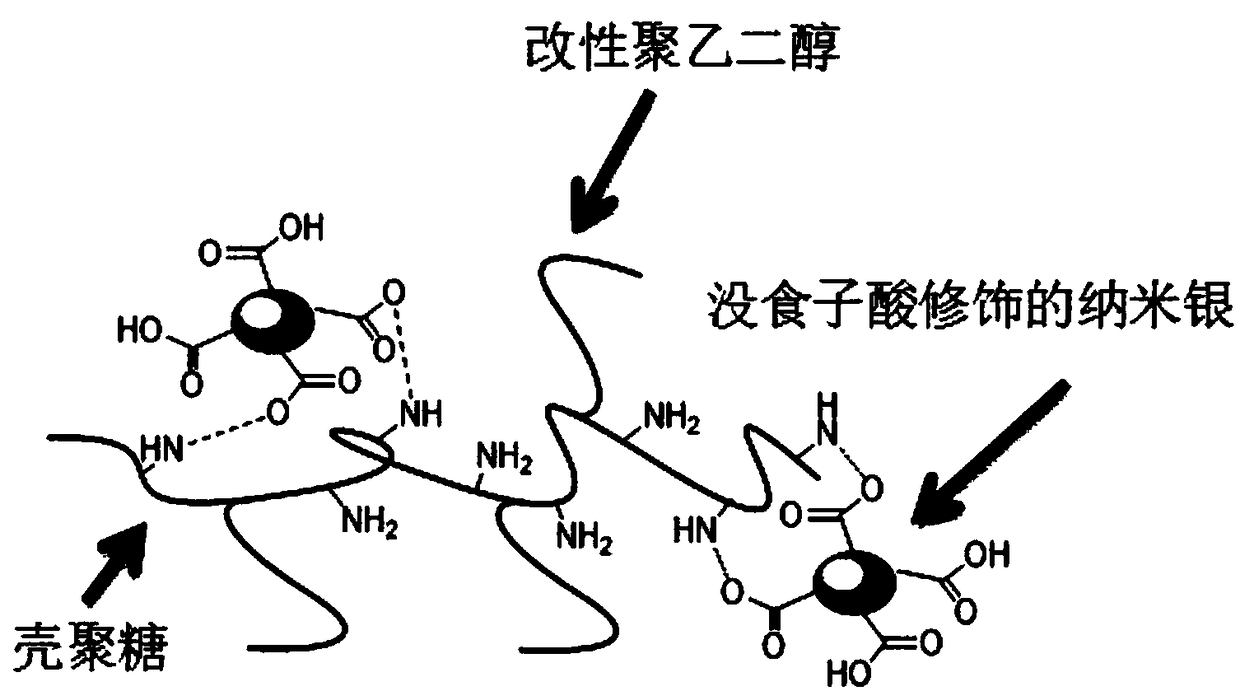

A composite antibacterial and coating technology, applied in the field of surface antibacterial, can solve the problems of limited application prospects and insufficient antibacterial performance of polymers, and achieve the effects of simple preparation method, significant synergistic antibacterial effect, and excellent antibacterial performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

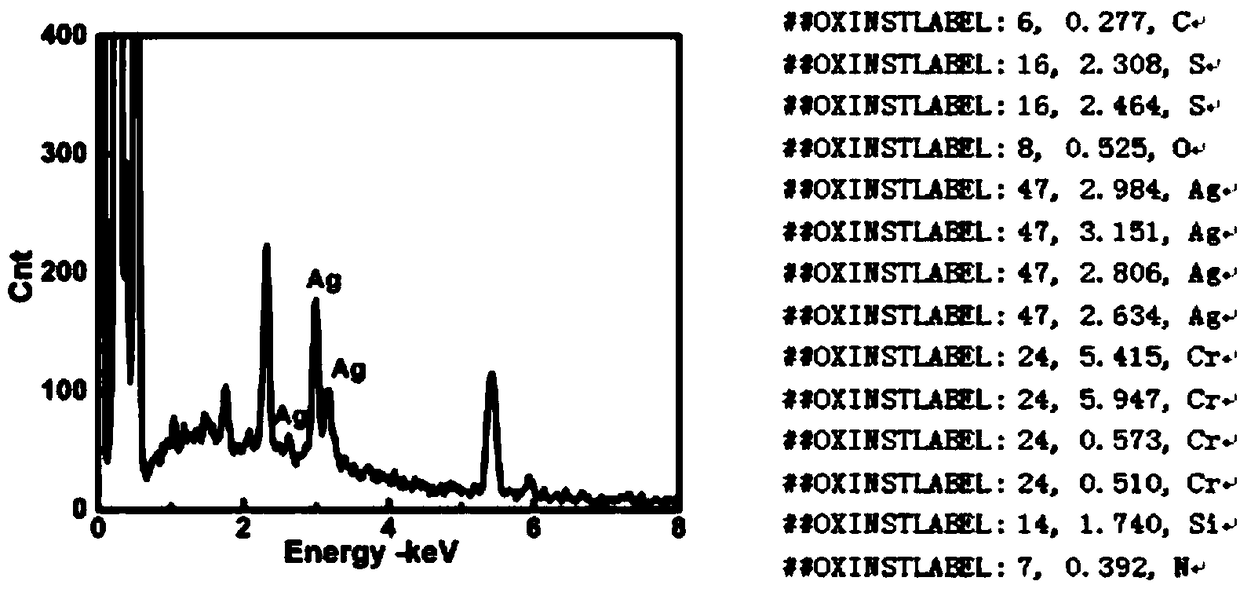

Examples

Embodiment 1

[0041] In the single-necked flask, 10g of chitosan with molecular weight of 10000 was dissolved in the aqueous solution of 30ml pH5.0, after fully dissolving, adding (III) molecular weight was 2000 Polyethylene Glycol 3g, and reacted under room temperature for 48 hours. After the reaction, the reaction solution was concentrated and freeze-dried, then fully washed with ethanol, and dried to obtain polyethylene glycol-grafted chitosan with a grafting rate of 2.4%, which was defined as PEG-g-CS 2.4% .

Embodiment 2

[0043] In the single-necked flask, 10g of chitosan with a molecular weight of 10000 was dissolved in the aqueous solution of 30ml pH5.0. After fully dissolving, add 3g of polyethylene glycol with a molecular weight of 1000 in the formula (III), and reacted for 48 hours at room temperature. After the reaction, the reaction solution was concentrated and freeze-dried, then fully washed with ethanol, and dried to obtain a polyethylene glycol-grafted chitosan with a grafting rate of 4.5%, which was defined as PEG-g-CS 4.5% .

Embodiment 3

[0045] In the single-necked flask, 10g of chitosan with a molecular weight of 10000 was dissolved in the aqueous solution of 30ml pH5.0, after fully dissolving, adding 3g of polyethylene glycol with a molecular weight of 12000 in the formula (III), reacted for 48 hours at room temperature. After the reaction finished, the reaction solution was concentrated and freeze-dried, then fully washed with ethanol, and dried to obtain the chitosan grafted with polyethylene glycol with a grafting rate of 0.4%, which was defined as PEG-g-CS 0.4% .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com