Polyurethane coating and preparation method thereof

A technology for polyurethane coatings and raw materials, applied in polyurea/polyurethane coatings, anti-corrosion coatings, antifouling/underwater coatings, etc., can solve problems such as poor overall performance, achieve excellent physical and mechanical properties, high efficiency, and improve mildew resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

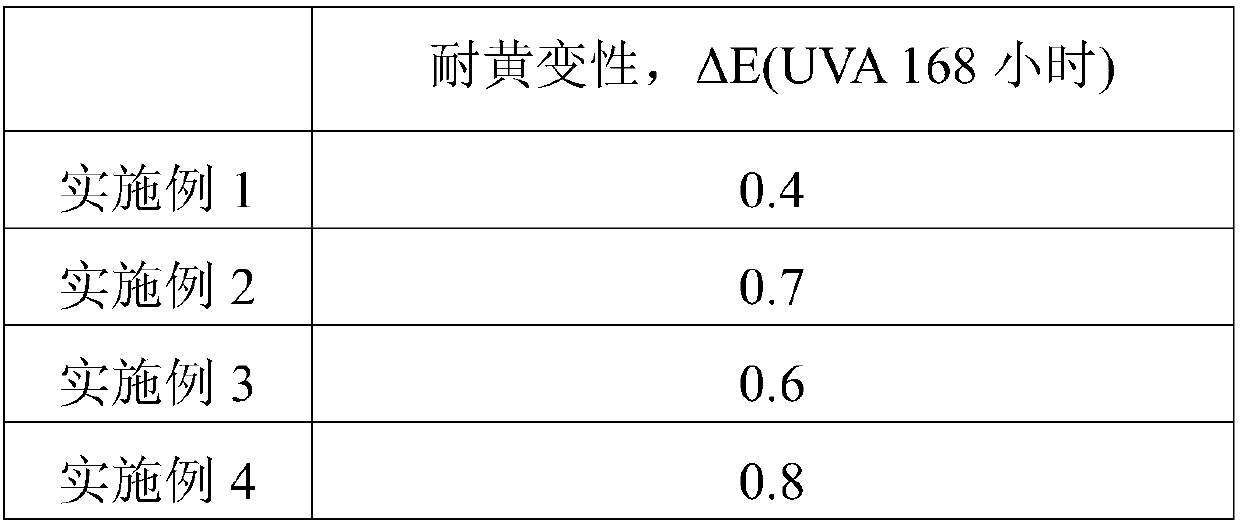

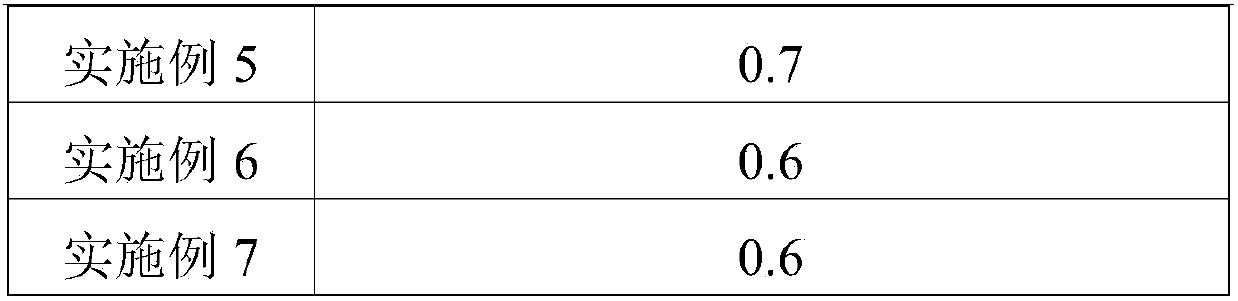

Examples

Embodiment 1

[0036] Polyurethane coating raw material (parts by weight):

[0037] Polyurethane coating raw material (parts by weight):

[0038] 30 parts of hydroxyethyl acrylate, 20 parts of butyl acrylate, 2 parts of methacryloxypropyl tris(trimethylsiloxane) silane, 1,3-bis(3-hydroxypropyl)-1,1 , 3 parts of 3,3-tetramethyldisiloxane, 0.5 parts of dibenzoyl peroxide, 0.5 parts of 3-mercapto-1-propanol, 0.3 parts of tetramethylammonium hydroxide, 30 parts of ethyl acetate, 35 parts of propylene glycol methyl ether acetate, 25 parts of 1,6-hexamethylene diisocyanate, 3 parts of inorganic antibacterial agent, and 1.5 parts of dispersant.

[0039] The inorganic antibacterial agent is obtained by stirring and mixing lithium carbonate, aluminum sulfate, and zinc oxide uniformly in a mass ratio of 1:1:1.

[0040] The dispersant is obtained by stirring and uniformly mixing sodium hexametaphosphate, sodium pyrophosphate and sodium trimetaphosphate in a mass ratio of 1:1:1.

[0041] Preparation ...

Embodiment 2

[0047] It is basically the same as Example 1, except that the inorganic antibacterial agent is obtained by stirring and mixing aluminum sulfate and zinc oxide uniformly at a mass ratio of 1:1. Obtain the polyurethane coating of embodiment 2.

Embodiment 3

[0049] It is basically the same as in Example 1, except that the inorganic antibacterial agent is obtained by stirring and mixing lithium carbonate and zinc oxide uniformly at a mass ratio of 1:1. Obtain the polyurethane coating of embodiment 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com