Antistatic polyurethane coating and preparation method thereof

A polyurethane coating and antistatic technology, applied in polyurea/polyurethane coatings, conductive coatings, anti-corrosion coatings, etc., can solve the problems of poor overall performance and achieve excellent physical and mechanical properties, convenient construction, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

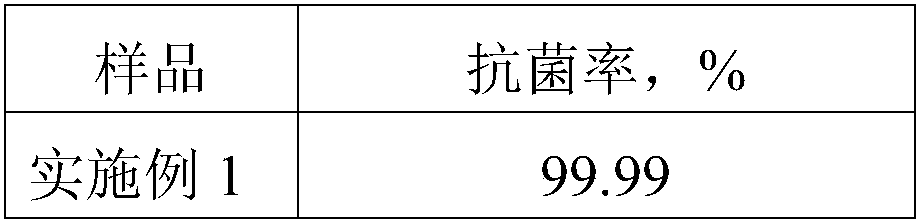

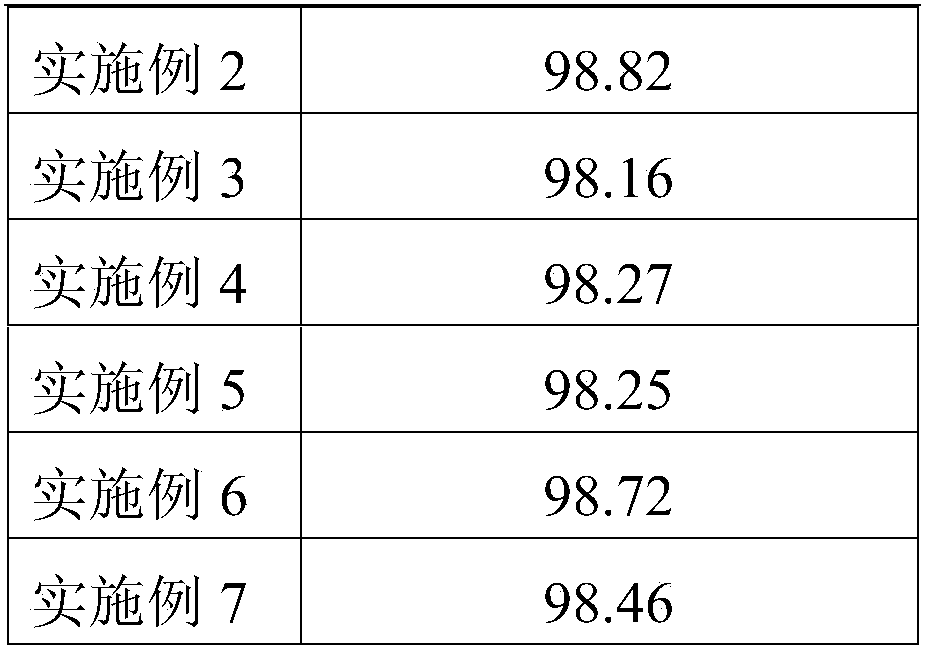

Examples

Embodiment 1

[0042] Antistatic polyurethane coating raw materials (parts by weight): 50 parts of water-based polyurethane emulsion, 35 parts of water-based acrylic resin, 3 parts of monododecyl phosphate sodium salt, 1.5 parts of octadecyltrimethylammonium chloride, silicon dioxide 10 parts, 0.5 parts of simethicone, 20 parts of ethanol, 20 parts of water, 3 parts of inorganic antibacterial agent, and 1.8 parts of dispersant.

[0043] The inorganic antibacterial agent is obtained by stirring and mixing lithium carbonate, aluminum sulfate, and zinc oxide uniformly in a mass ratio of 1:1:1.

[0044] The dispersant is obtained by stirring and uniformly mixing sodium hexametaphosphate, sodium pyrophosphate and sodium trimetaphosphate in a mass ratio of 1:1:1.

[0045] The preparation method of antistatic polyurethane coating: water-based polyurethane emulsion, water-based acrylic resin, monolauryl phosphate sodium salt, octadecyl trimethyl ammonium chloride, silicon dioxide, simethicone, ethan...

Embodiment 2

[0047] It is basically the same as Example 1, except that the inorganic antibacterial agent is obtained by stirring and mixing aluminum sulfate and zinc oxide uniformly at a mass ratio of 1:1. Obtain the antistatic polyurethane coating of embodiment 2.

Embodiment 3

[0049] It is basically the same as in Example 1, except that the inorganic antibacterial agent is obtained by stirring and mixing lithium carbonate and zinc oxide uniformly at a mass ratio of 1:1. Obtain the antistatic polyurethane coating of embodiment 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com