Biological organic-inorganic large-particle fertilizer and preparation method thereof

A bio-organic, inorganic, granular technology, applied in organic fertilizers, fertilizer mixtures, solid/semi-solid fertilizers, etc., can solve the problems of limited adsorption and protection of beneficial microorganisms, loss of biological fertilizer activation nutrients, and low activity of beneficial microorganisms. Improve soil physical and chemical properties, enhance fertilization effect, and protect microbial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

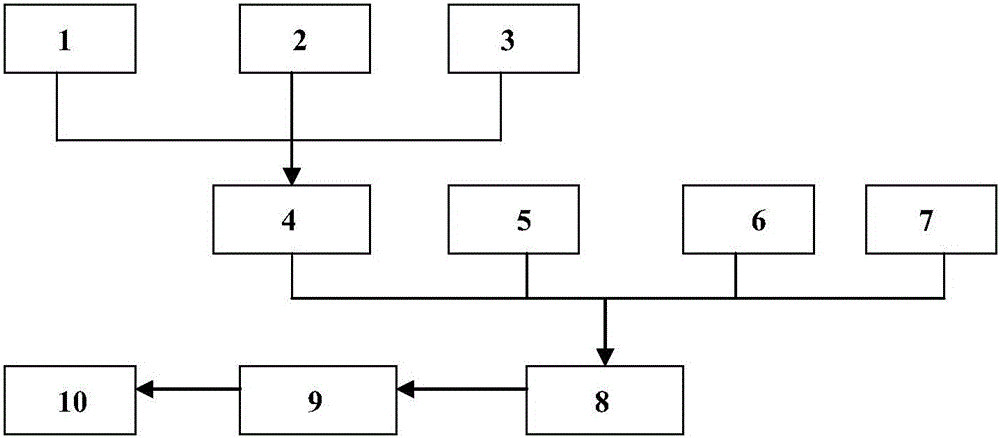

Method used

Image

Examples

Embodiment approach 1

[0029] Put 25Kg of commercially available organic fertilizer (water content 10-20%), 23.5Kg of long-acting nitrogen-phosphorus compound fertilizer and 0.5Kg of Bacillus polymyxa bacteria powder into a ball mill to stir and mix to obtain powdery blended fertilizer. Then add 0.25Kg of quartz sand, 0.25Kg of a mixture of commercially available fluorspar powder and montmorillonite according to a weight ratio of 1:1, and 0.5Kg of commercially available amino acid in the above-mentioned powdery blended fertilizer, fully mix the above materials and stir quickly, The evenly stirred mixture is put into the tablet press, and the coefficient of the tablet press is adjusted: the pressure is 80T, the temperature is 30°C, the injection time is 2 seconds, and the extrusion time is 3.5 seconds, and the super-large particles in the extrusion state can be generated. Humic acid fertilizer granules (3-8cm in height, 3-5cm in diameter, 50-100g / grain in weight). The fertilizer produced by the above...

Embodiment approach 3

[0032] Put 20Kg of commercially available organic fertilizer, 28.9Kg of long-acting nitrogen-phosphorus compound fertilizer and 0.5Kg of Bacillus polymyxa bacteria powder into a ball mill to stir and mix to obtain powdery blended fertilizer. Add 0.05Kg of quartz sand, 0.05Kg of a mixture of commercially available fluorspar powder and montmorillonite according to a weight ratio of 1:1, and 0.5Kg of commercially available amino acid to the powdery blended fertilizer, fully mix the above materials and stir quickly, and stir Put the uniform mixture into the tablet press, and adjust the coefficient of the tablet press: pressure 90T, temperature 35°C, injection time 2 seconds, extrusion time 3.5 seconds, and the extrusion state can be generated within 1 minute. Super large particle humic acid fertilizer (particle height 3-8cm, diameter 3-5cm, weight 50-100g / grain). The fertilizer produced by the above process is stored in a sealed bag under normal temperature and dry conditions. It ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com