A kind of composite petroleum coke-based activated carbon and its preparation method, supercapacitor

An activated carbon and composite technology, applied in hybrid capacitor electrodes, chemical instruments and methods, carbon compounds, etc., can solve the problems of high internal resistance, far difference in energy density, low specific capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The invention provides a kind of preparation method of composite petroleum coke-based activated carbon, comprising the following steps:

[0045] A) After coking the petroleum coke particles treated with the oxidative medium under the condition of the first gas, an activated carbon precursor is obtained;

[0046] B) after the activated carbon precursor obtained in the above steps is mixed with alkali, preactivation is carried out under the condition of the second gas, and then activated under the condition of the third gas, and then the activated carbon dispersion is obtained after washing;

[0047] C) mixing the activated carbon dispersion obtained in the above steps with the graphene oxide solution, drying, and then heat-treating under protective gas conditions to obtain a composite petroleum coke-based activated carbon.

[0048] In the present invention, firstly, the petroleum coke particles treated with an oxidative medium are coked under the condition of the first gas...

Embodiment 1

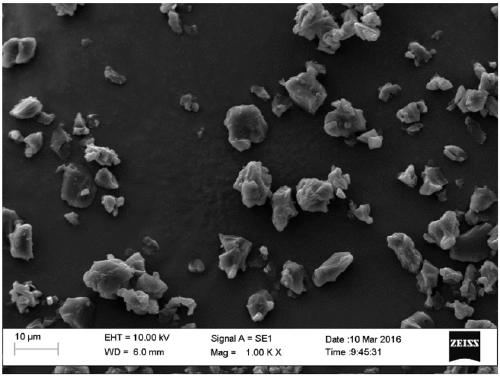

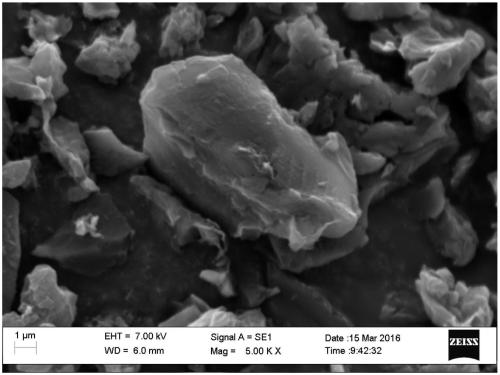

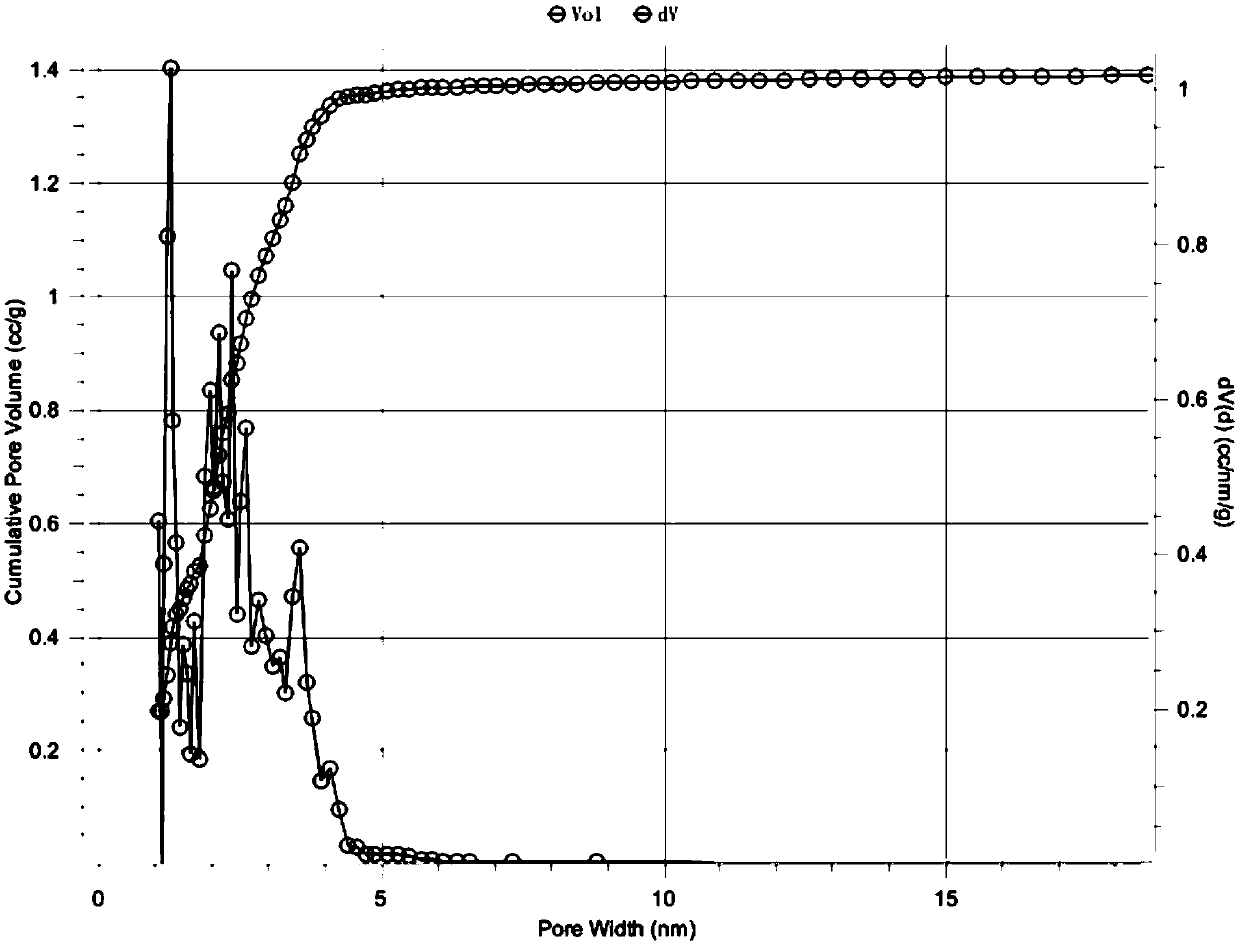

[0076] Take 100g of high-quality petroleum coke and crush it into 8-12μm particles, add 500mL of 30% hydrogen peroxide, heat to 50°C and soak for 2h, filter, wash, and dry; heat to 450°C under air for 45min, cool naturally, add 100g of powder of KOH and mix well. Put this mixture into a metal nickel crucible, raise the temperature to 450°C at a rate of 10-20°C / min under nitrogen atmosphere and keep it for 3h; . Dissolve the product in water, wash repeatedly until neutral, then add 6M hydrochloric acid to reflux for 2 hours, filter, wash with deionized water until neutral; add deionized water to make a 5% aqueous dispersion; add solid A monolayer graphene oxide solution (0.5%, 100 mL) with a content of 0.5 g and 0.5 g of melamine was ultrasonically stirred for 1 h and spray-dried. Put the obtained solid powder into a rotary furnace, raise the temperature to 800° C. under 10% hydrogen-nitrogen mixed gas and keep it for 2 hours, cool down, and magnetically separate to obtain su...

Embodiment 2

[0082] Take 100g of high-quality petroleum coke and crush it into 50-100μm particles, add 500mL of 1M nitric acid and reflux for 6h, filter, wash, and dry; heat the material to 350°C under air for 60min, and cool naturally. Add 50g KOH dissolved in ethanol to the material, mix evenly and heat to remove the solvent. Put this mixture into a metal nickel crucible, raise the temperature to 500°C at a rate of 10-20°C / min under nitrogen atmosphere and keep it for 1h; . Dissolve the product in water, wash repeatedly until neutral, then add 6M hydrochloric acid to reflux for 2 hours, filter, wash with deionized water until neutral; add deionized water to make a 5% aqueous dispersion; add solid A monolayer graphene oxide solution (0.5%, 100 mL) with a content of 0.2 g and 2.0 g of melamine was ultrasonically stirred for 1 h, and then spray-dried. Put the obtained solid powder into a rotary furnace, raise the temperature to 850°C under 10% ammonia-argon gas mixture and keep it for 1.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com