A stainless steel strip submerged arc surfacing flux

A technology of stainless steel strip and flux, applied in the direction of welding equipment, welding medium, welding/cutting medium/material, etc., to achieve the effect of excellent intergranular corrosion performance, smooth lap joint, and excellent comprehensive welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

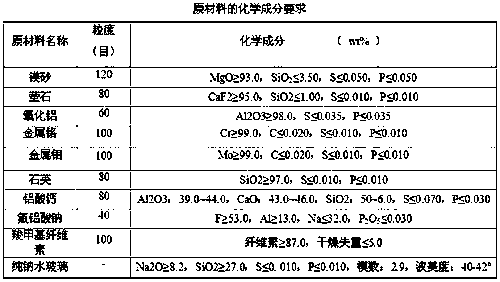

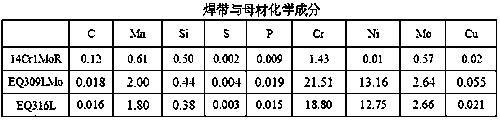

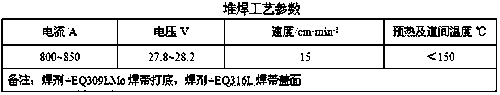

Method used

Image

Examples

Embodiment 1

[0033] A stainless steel strip submerged arc surfacing flux that can carry out post-weld heat treatment. According to the weight percentage, the flux consists of 31% magnesia, 6% fluorite, 15% alumina, 3% metal chromium, 4% It is made of metal molybdenum, 12% quartz, 3% sodium fluoroaluminate, 4% calcium aluminate, 1% carboxymethyl cellulose and 21% pure sodium water glass.

Embodiment 2

[0035] A stainless steel strip submerged arc surfacing flux that can carry out post-weld heat treatment. According to the weight percentage, the flux consists of 31% magnesia, 4% fluorite, 13% alumina, 2% metal chromium, 3% It is made of metal molybdenum, 14% quartz, 4% sodium fluoroaluminate, 3% calcium aluminate, 2% carboxymethyl cellulose and 24% pure sodium water glass.

Embodiment 3

[0037] A stainless steel strip submerged arc surfacing flux that can carry out post-weld heat treatment. According to the weight percentage, the flux consists of 33% magnesia, 3% fluorite, 12% alumina, 3% metal chromium, 4% It is made of metal molybdenum, 13% quartz, 5% sodium fluoroaluminate, 2% calcium aluminate, 3% carboxymethyl cellulose and 22% pure sodium water glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com