Steel pipe plastic coating hot air furnace

A technology of hot blast stove and hot air, which is applied in the direction of coating, liquid coating device on the surface, surface pretreatment, etc., which can solve the problems of dirt on the surface of the steel pipe, uneven temperature, waste of energy, etc., and achieve temperature reduction and temperature rise Fast speed and the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

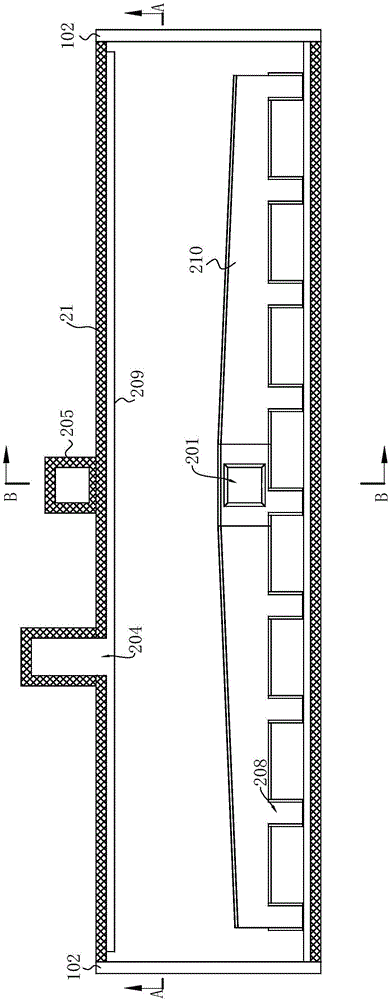

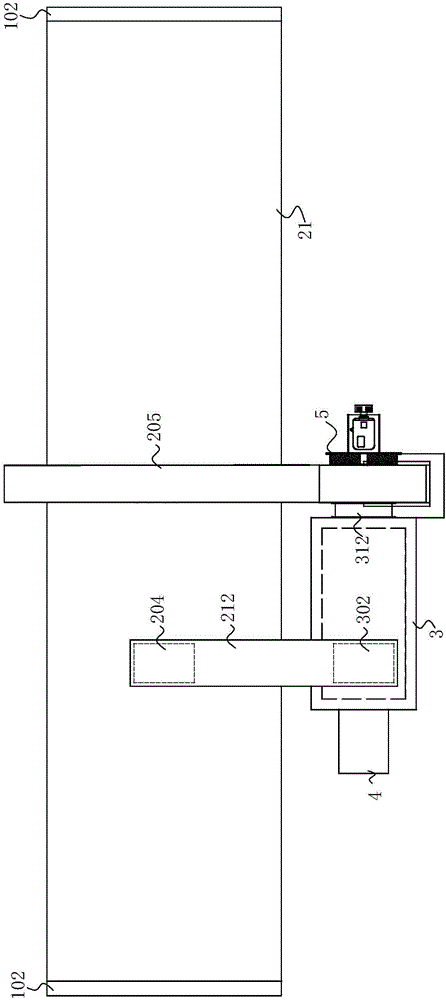

[0032] like Figure 1 to Figure 3 Commonly shown, a steel pipe plastic-coated hot air furnace includes a hot air drying tunnel 21 and a combustion chamber, and the combustion chamber is located outside the hot air drying tunnel 21 .

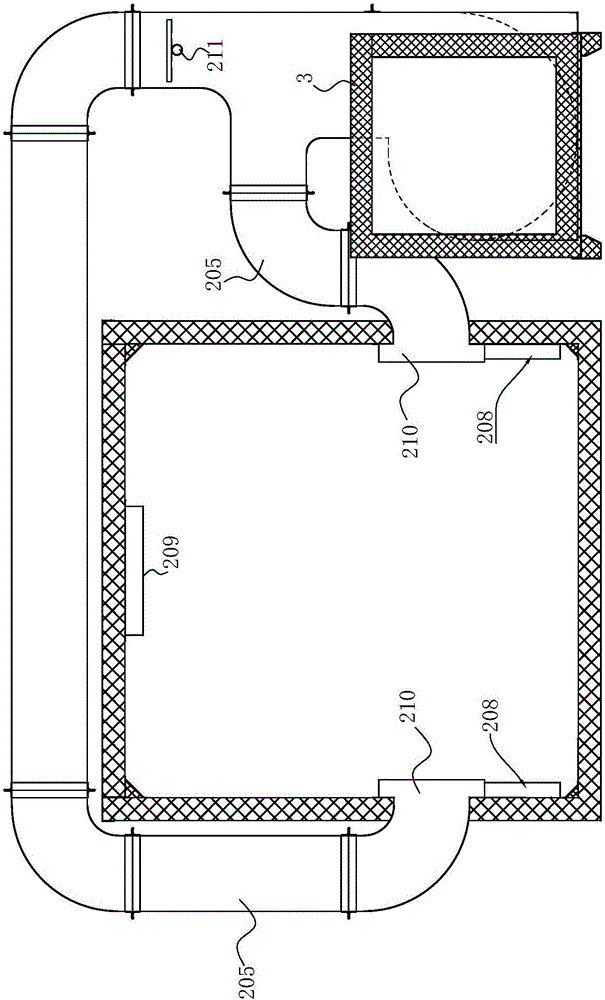

[0033] combine Image 6 As shown, the hot blast stove combustion chamber includes a housing 3, the housing 3 includes a first end 31 and a second end 32 oppositely arranged, and a side 33 is between the first end 31 and the second end 32, and the second One end 31 is provided with a flame injection port 311 for installing the burner 4 , and the second end 32 is provided with an air outlet 312 from which hot air is discharged, and the air outlet 312 is connected to the fan 5 . The side portion 33 of the casing 3 is provided with an air return port 302 through which the combustion chamber can recycle hot air, thereby reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com