Rapid assembly clamp for right-angled plate

An assembly fixture and right-angle technology, applied in the field of plate processing, can solve problems such as affecting the bonding strength and appearance of products, unguaranteed product quality, uneven drying, etc., to avoid bonding strength and affecting appearance, improve Assembly efficiency, fast and even drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

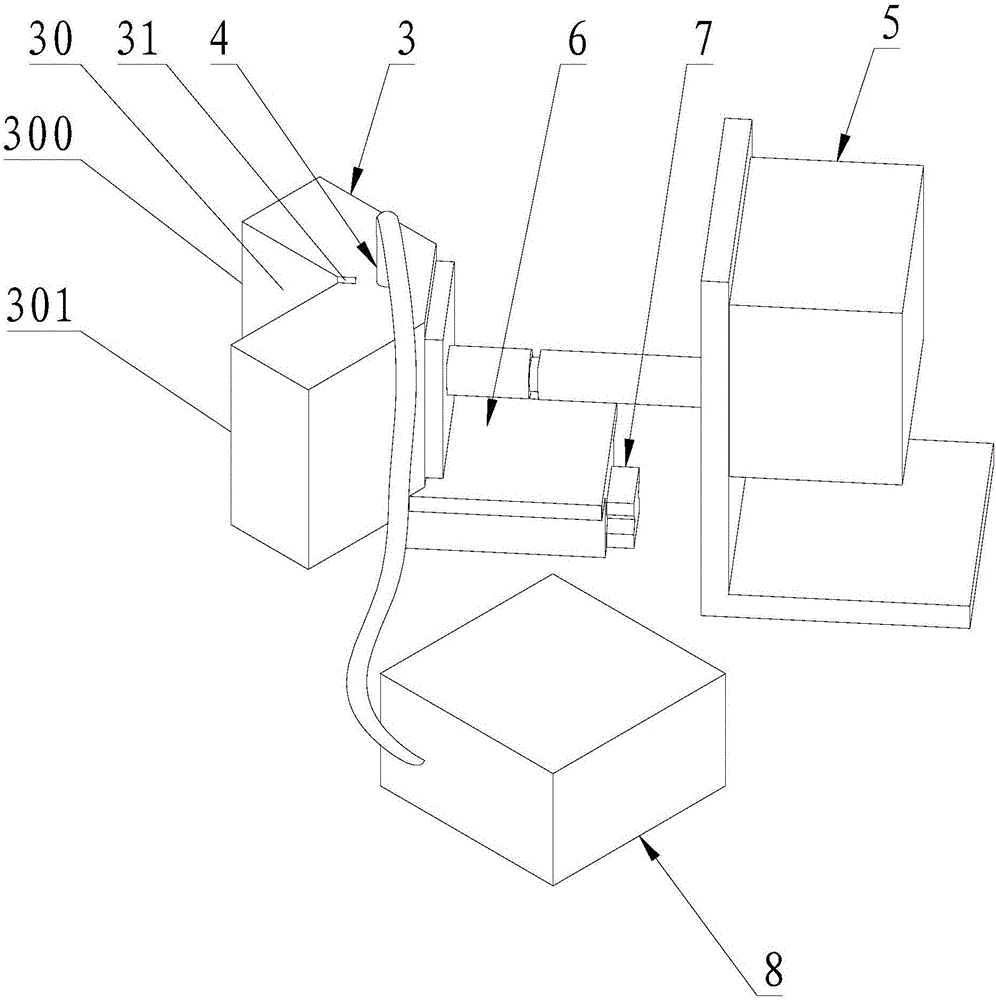

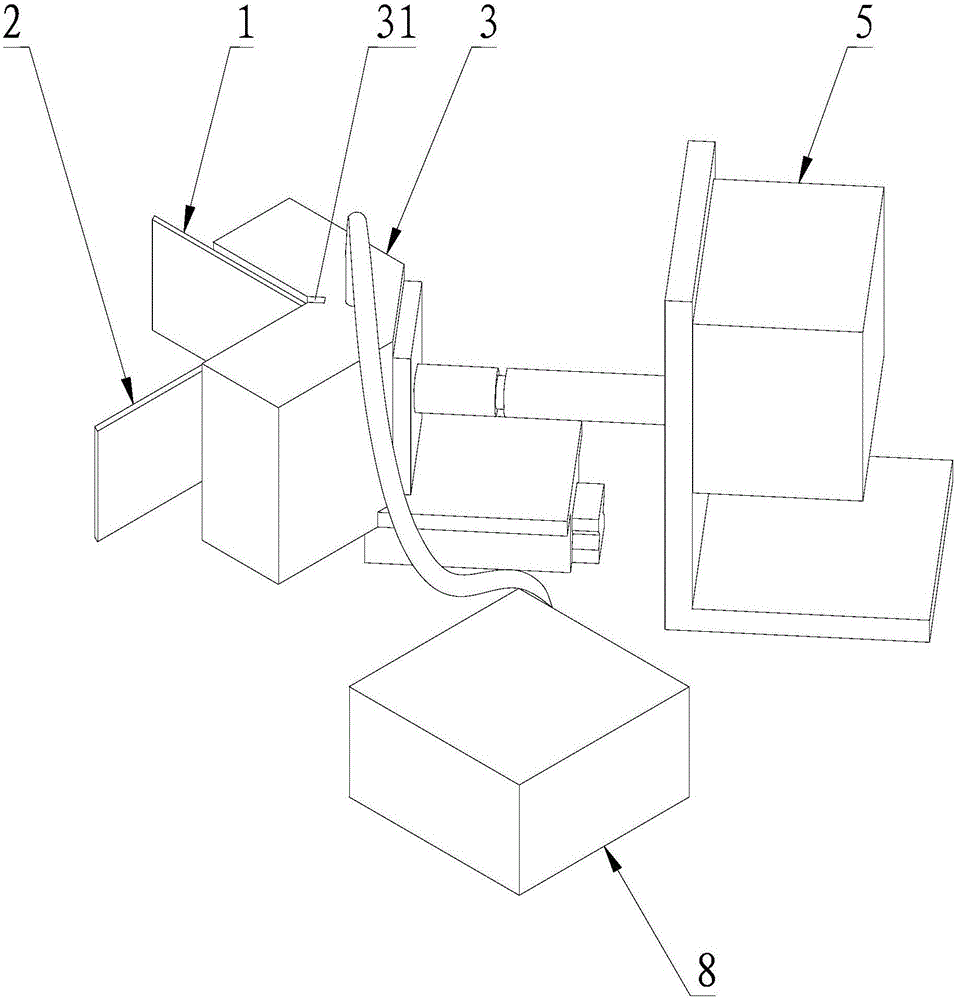

[0024] Please refer to figure 2 and image 3 Shown, embodiment one of the present invention is:

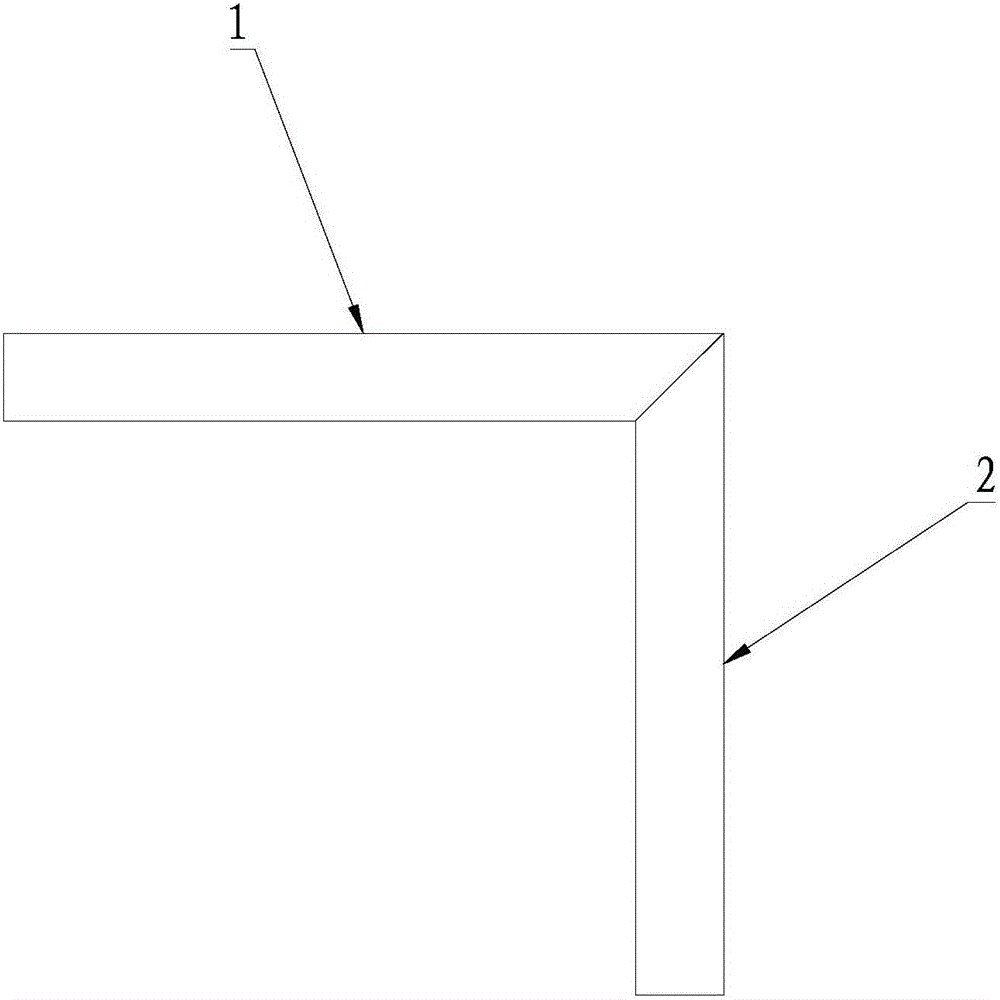

[0025] A jig for quick assembly of right-angled boards, including a jig body 3 and an electric heating rod 4, the side of the jig body 3 is provided with a right-angle groove 30, and the groove wall of the right-angle groove 30 is composed of first clamping surfaces perpendicular to each other 300 and the second clamping surface 301, the intersection of the first clamping surface 300 and the second clamping surface 301 is provided with a glue removal groove 31, and the upper and lower ends of the glue removal groove 31 are respectively connected to the top of the clamp body 3 On the surface and the bottom surface, the fixture body 3 is provided with an electric heating rod installation hole, and the electric heating rod 4 is installed in the electric heating rod installation hole to heat the fixture body 3 . The heating rod installation hole is vertically opened on the clamp bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com