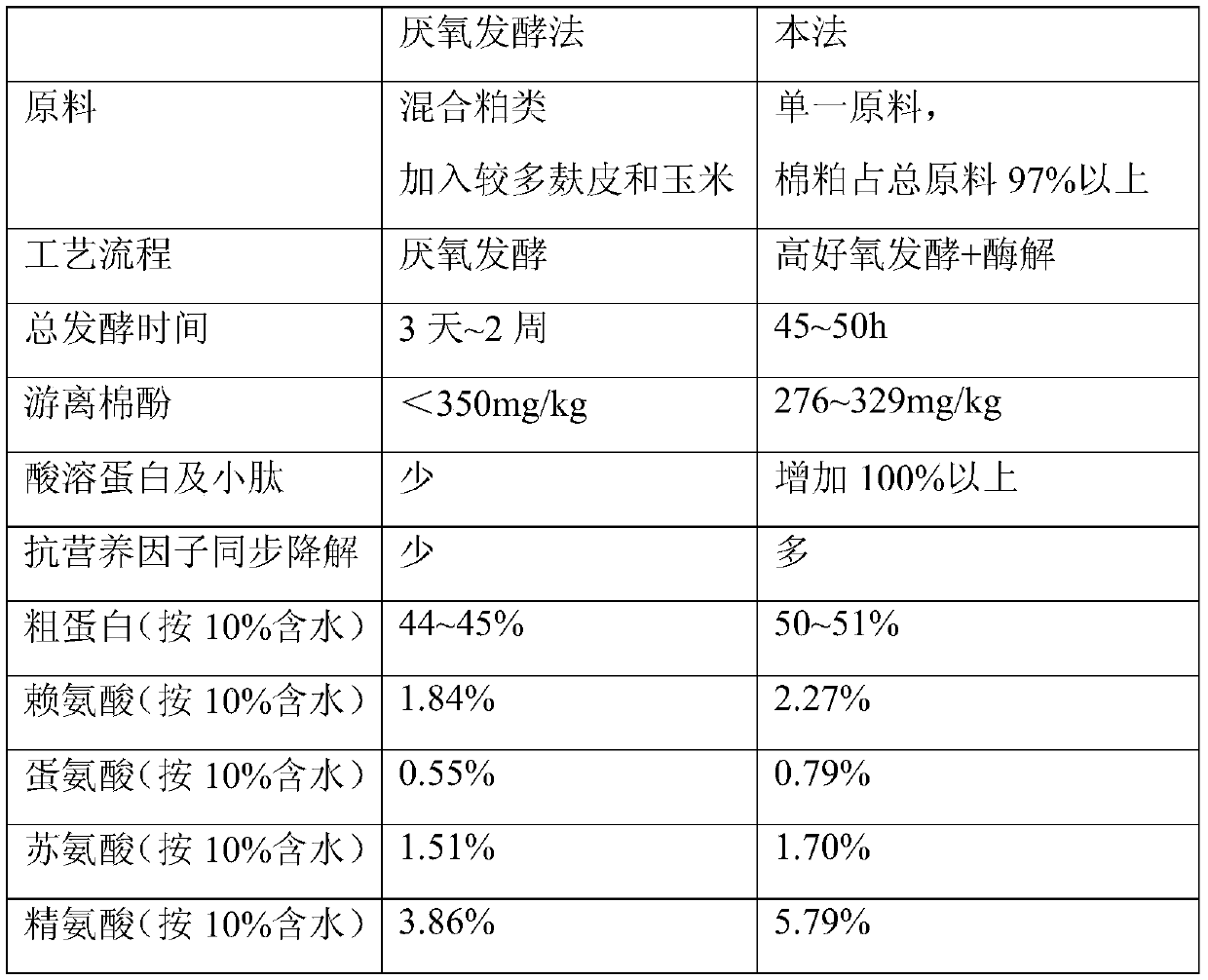

Method for preparing fermented cottonseed protein by fermenting cottonseed protein and solid-state aerobic fermentation

A cottonseed protein and preparation technology, applied in fermentation, animal husbandry, hydrolytic enzymes, etc., can solve the problems of low fermentation efficiency and unoptimized raw materials, improve the breeding environment, and be conducive to the harmlessness and resource utilization of feces. The effect of enhancing disease resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Example 1 Cotton Meal Screening Pretreatment Conditions

[0056] The cotton meal raw material is pulverized with an industrial pulverizer, and the sieve of the pulverizer is 2.0 mm. Sieve the crushed cottonseed meal with 10 mesh, 20 mesh, 30 mesh, 40 mesh, 60 mesh and 80 mesh screens respectively, and weigh the weight of the sieve and the sieve respectively. Among them, the 10-mesh sieve is all short fluff, accounting for about 2% of the total weight of raw materials; the 20-mesh sieve is short fluff and a small amount of cottonseed husk impurities, accounting for about 8% of the total raw material weight, and the under-sieve is not visible to the naked eye. The short fluff; from 30 mesh to 80 mesh sieving results, the cotton kernels in the sieve material increase with the finer sieve holes. Based on the above, 20-30 mesh sieving is selected as the pretreatment before fermentation to reduce the content of impurities such as fiber substances. Preferably 20 meshes, anal...

Embodiment 2

[0057] The preparation of embodiment 2 solid production bacterial classification

[0058] Pick 1 loop (inoculation loop) from the slant-preserved strain of Saccharomycopsis fibuligera, insert it into 100mL potato culture solution, and culture it in a shaker flask (180rpm) at 30°C for 52h to obtain Saccharomycopsis fibuligera. Hymenospora yeast culture medium.

[0059] Take 50g of yeast liquid of S. forticulata, add it into 5000g of sterilized bran corn culture medium (calculated as dry material), mix evenly, and cultivate at 30°C for 48h to obtain solid yeast of S. forticulata. strains.

[0060] Preparation of potato sucrose culture solution: Peel fresh potatoes and cut them into thumb-sized chunks, weigh 100g, add 500g of tap water, boil for 20 minutes, filter with gauze, discard the residue and take the supernatant, and dilute with tap water to 500g, then add 10g of sucrose, after melting, pack into 250ml Erlenmeyer flasks, 100g per bottle. Sterilization was maintained at...

Embodiment 3

[0064] The addition of embodiment 3 nutrient salts is on the impact of processing result

[0065] The cottonseed meal raw material is pulverized according to Example 1, and sieved with 20 mesh to obtain cottonseed meal powder. Then prepare mixed yeast solid strain according to Example 2.

[0066] Will KH 2 PO 4 , KCl, MgSO 4 , FeSO 4 , ZnSO 4Add phytase and phytase in groups according to the table, mix evenly, incubate at 30°C for 48 hours, and measure the cell number and crude protein content after fermentation.

[0067] 1 2 3 4 5 6 7 8 Cotton meal powder (g) 1000 1000 1000 1000 1000 1000 1000 1000 water (g) 700 700 700 700 700 700 700 700 Strains (g) 5 5 5 5 5 5 5 5 K H 2 PO 4 (g)

[0068] Select nutrient salt addition as the eighth group, namely: KCl 0.1%, MgSO 4 0.05%, FeSO 4 0.005%, ZnSO 4 0.0025%, phytase 0.02%. The decomposition of phytic acid in cotton meal by phytase can provide phosphorus sour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com