A method for preparing environment-friendly carboxylate calcium magnesium salt deicing agent by using flue gas desulfurization waste

A technology for desulfurization waste and calcium carboxylate, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of large changes in urban sludge composition, difficulty in ensuring product quality, and increased marginal benefits, and achieve good industrial applications. Prospects, full and effective treatment, the effect of reducing the marginal cost of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Put 100 g of flue gas desulfurization waste into the reaction kettle, and add 150 g of carboxylic acid. Under 1-1.5 atmospheric pressure, control the temperature of the reactor to 80°C for the reaction, and use 30% sodium hydroxide solution to absorb the acid gas generated during the reaction. After the reaction, the remaining solid-liquid mixture in the reactor was filtered. Collect the filtrate, decolorize it with activated carbon, then dry and concentrate the filtrate in an oven at 110°C for 3-5 days, then grind it to obtain the product. 60.5 g of product are obtained.

Embodiment 2

[0023] Put 80 g of flue gas desulfurization waste into the reaction kettle, and add 130 g of carboxylic acid. Under 1-1.5 atmospheric pressure, control the temperature of the reactor to 90°C for the reaction, and use 30% sodium hydroxide solution to absorb the acid gas in the reaction process. After the reaction, the remaining solid-liquid mixture in the reactor was filtered. Collect the filtrate, decolorize it with activated carbon, then dry and concentrate the filtrate in an oven at 105°C for 3 to 5 days, then grind it to obtain the product, and weigh 58.5g of the product.

Embodiment 3

[0024] Example 3: Put 150 g of flue gas desulfurization waste into a reaction kettle, and add 200 g of carboxylic acid. Under 1-1.5 atmospheric pressure, control the temperature of the reactor to 70°C for the reaction, and use 30% sodium hydroxide solution to absorb the acid gas in the reaction process. After the reaction, the remaining solid-liquid mixture in the reactor was filtered. Collect the filtrate, decolorize it with activated carbon, then dry and concentrate the filtrate in an oven at 100°C for 3-5 days, then grind it to obtain the product, and obtain 45.1 g of the product by weighing.

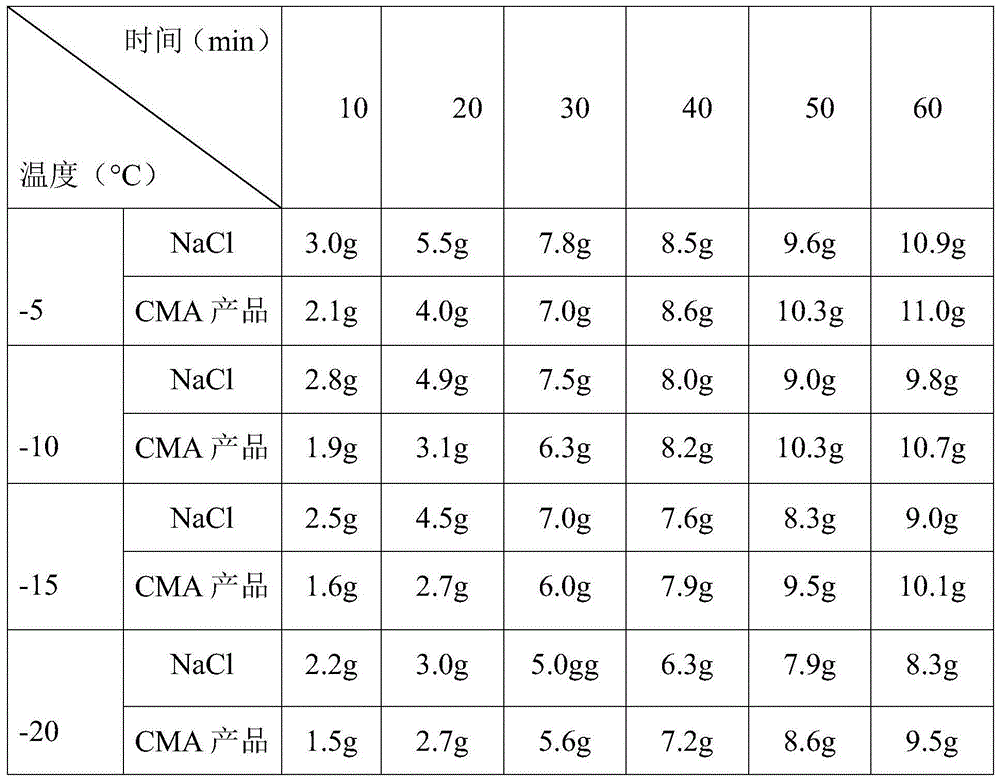

[0025] Application effect test of the present invention:

[0026] (1) Ice-melting ability

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com