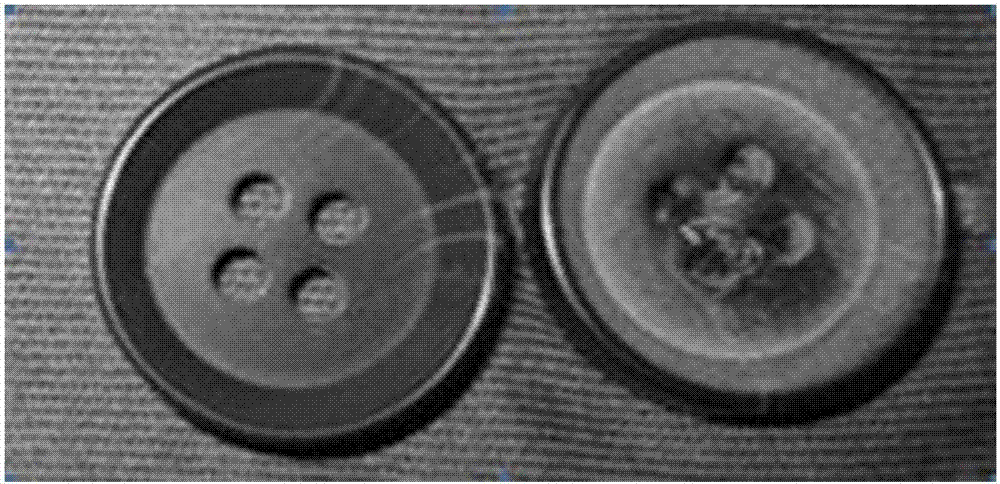

How to deal with button white circle

A processing method and button technology, applied in the direction of using liquid cleaning methods, chemical instruments and methods, cleaning methods and utensils, etc., can solve problems such as customer complaints, and achieve the effect of elimination, stable effect, and labor cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for processing button white circles, comprising the following steps:

[0033] (1) Put 400 kg of tap water or circulating water (submerged in the drum of the ultrasonic machine, and the liquid level is 1 to 3 cm higher than the drum) and 8 kg of DF1 into the drum ultrasonic cleaning machine in turn, and start the machine to fully mix DF1 with water; Shut down, add all-optical unsaturated polyester buttons (glossiness is greater than 80 degrees; the glossiness of the button of the embodiment of the present invention is detected by a glossmeter, purchased from Fuwei Optoelectronics) into the drum of the drum ultrasonic cleaning machine, The volume of the button can account for 1 / 2 of the volume of the drum;

[0034] (2) Put the drum on the corresponding station in the drum ultrasonic cleaning machine, turn on the rotating motor, adjust the speed to 10-20 rpm, turn on the ultrasonic generator, and adjust the power to 4KW; set the processing time 60 minutes;

[00...

Embodiment 2

[0040] A method for processing button white circles, comprising the following steps:

[0041] (1) Put about 400 kg of tap water or circulating water into the drum ultrasonic cleaning machine in turn (submerge the drum of the ultrasonic machine, and the liquid level is 1-3 cm higher than the drum), 6 kg of DF1 and 6 kg of DF2, and turn on the machine to make DF1 , DF2 solution and water are fully mixed; stop, add semi-matte unsaturated polyester buttons (glossiness is 30 degrees to 80 degrees) into the drum of the drum ultrasonic cleaning machine, the volume of the buttons accounts for 30% of the volume of the drum 2 / 3 is enough;

[0042] (2) Put the drum on the corresponding station of the ultrasonic machine, turn on the rotating motor, adjust the speed to 10-20 rpm, turn on the ultrasonic generator, and adjust the power to 4KW; set the processing time to 50 minutes;

[0043] (3) After the time is up, take out the drum, pour out the buttons, clean the residual liquid on the s...

Embodiment 3

[0047] A method for processing button white circles, comprising the following steps:

[0048](1) Put about 400 kg of tap water or circulating water (submerged in the drum of the ultrasonic machine, and the liquid level is 1 to 3 cm higher than the drum) and 16 kg of DF2 into the drum ultrasonic cleaning machine in turn, and start the machine to fully mix DF2 with water ;Stop the machine, add full matte unsaturated polyester buttons (gloss less than 30 degrees) into the drum of the drum ultrasonic cleaning machine, the volume of the button accounts for 4 / 5 of the volume of the drum;

[0049] (2) Put the drum on the corresponding station of the drum ultrasonic cleaning machine, turn on the rotating motor, adjust the speed to 10-20 rpm, turn on the ultrasonic generator, and adjust the power to 4KW; set the processing time to 40 minutes;

[0050] (3) After the time is up, take out the drum, pour out the buttons, clean the residual liquid on the surface of the buttons with clean w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com