Nuclear power plant containment cooling system

A nuclear power plant containment and cooling system technology, which is applied in the field of nuclear power plant safety, can solve problems affecting the safety and economy of nuclear power plants, and achieve the effects of enhancing hot air conduction capability, improving heat exchange efficiency, and enhancing reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following descriptions of various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be implemented.

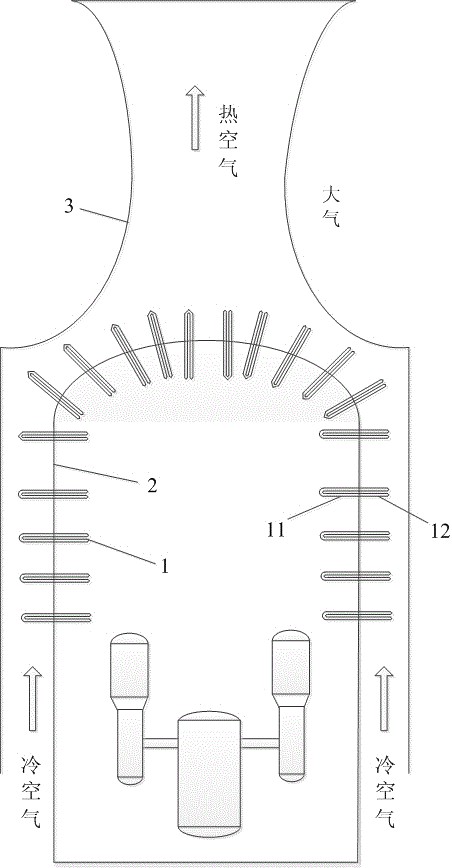

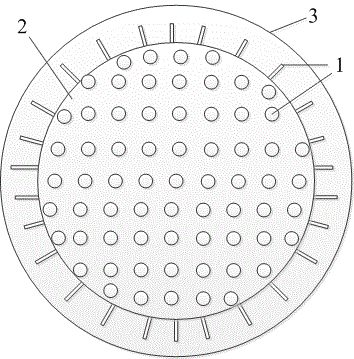

[0022] Please refer to figure 1 As shown, Embodiment 1 of the present invention provides a nuclear power plant containment cooling system, including:

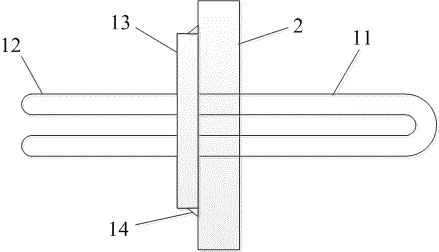

[0023] A plurality of heat exchange units 1 arranged on the surface of the containment vessel 2, the heat exchange units 1 include a hot section 11 located inside the containment vessel and a cold section 12 located outside the containment vessel, the heat exchange units are used to sequentially pass through the The hot section 11 and the cold section 12 export the heat of the steam inside the containment vessel to the outside of the containment vessel 1 .

[0024] Specifically, in this embodiment, the heat exchange unit 1 is an oscillating flow heat pipe. The oscillating flow heat pipe is made of a flexible common small-diameter metal pipe, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com