MEMS (micro electro mechanical system) silica-based micro-hotplate provided with thermal insulation channels and processing method of MEMS silica-based micro-hotplate

A processing method and a technology of a micro-hot plate, which are applied in the process, micro-structure technology, micro-structure device and other directions for producing decorative surface effects, can solve the problems of poor heat insulation effect, influence of heat insulation effect, and rapid heat loss, etc. Achieve the effect of preventing cracks, avoiding damage to the micro-hot plate, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

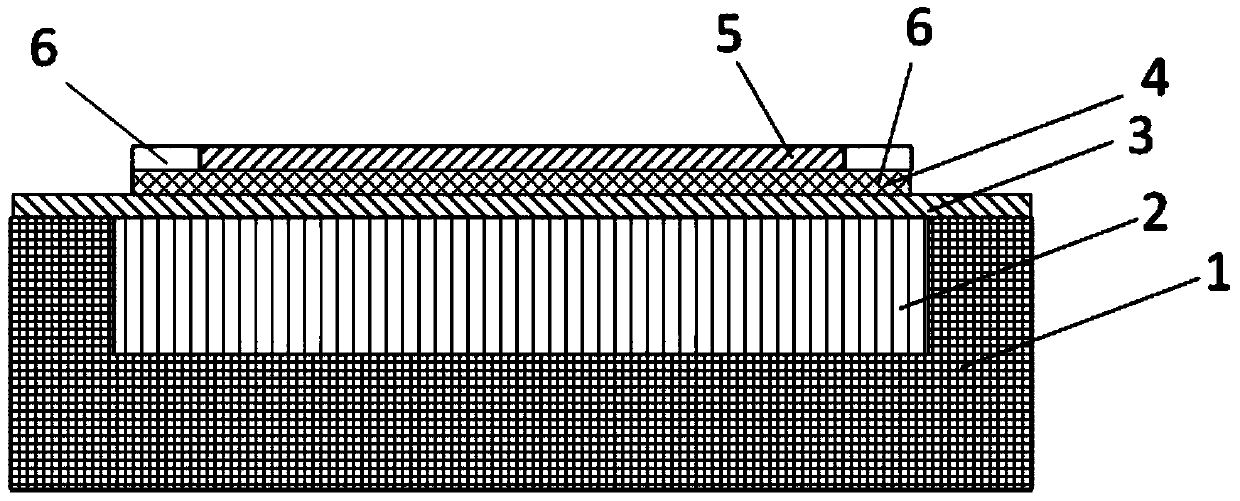

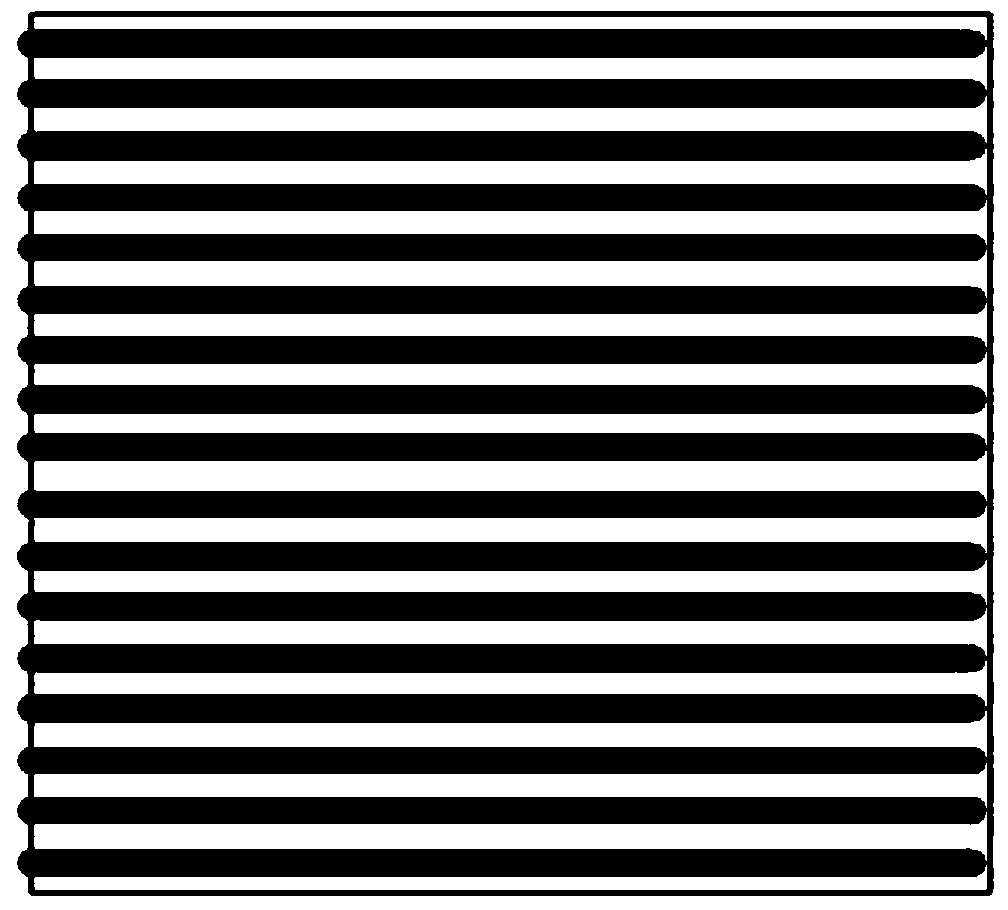

[0051] See figure 1 , figure 2 , Embodiment 1 of the present invention discloses a MEMS silicon-based micro-hot plate with thermal insulation grooves, comprising: a single crystal silicon substrate 1; a thermal insulation groove 2 formed on the upper surface of the single crystal silicon substrate 1 and With a certain depth, the thermal insulation groove 2 includes one or more groups of grooves, wherein each group of grooves includes a plurality of linear grooves arranged in parallel; the lower insulating layer 3 covers the thermal insulation groove 2 and the single crystal silicon The upper surface of the substrate 1; the heating layer 4 is arranged on the upper surface of the lower insulating layer 3, and the heating layer 4 is located in the area directly above the heat insulating trench 2; the upper insulating layer 5 covers the The upper surface of layer 4 is heated.

[0052] The heating layer 4 of the present invention is located in the area directly above the heat-in...

Embodiment 2

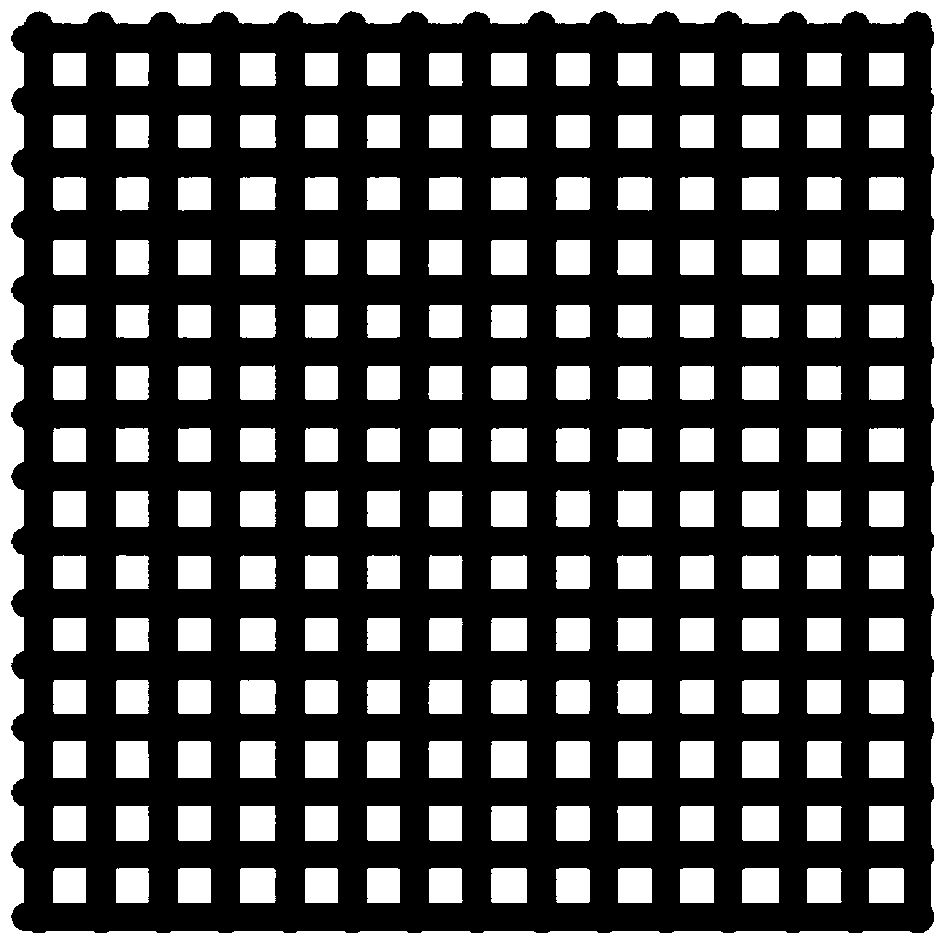

[0091] See figure 1 , image 3 , Embodiment 2 of the present invention discloses a MEMS silicon-based micro-hot plate with thermal insulation grooves, comprising: a single crystal silicon substrate 1; a thermal insulation groove 2 formed on the upper surface of the single crystal silicon substrate 1 and With a certain depth, the thermal insulation groove 2 includes one or more groups of grooves, wherein each group of grooves includes a plurality of linear grooves arranged in parallel; the lower insulating layer 3 covers the thermal insulation groove 2 and the single crystal silicon The upper surface of the substrate 1; the heating layer 4 is arranged on the upper surface of the lower insulating layer 3, and the heating layer 4 is located in the area directly above the heat insulating trench 2; the upper insulating layer 5 covers the The upper surface of layer 4 is heated.

[0092] The heating layer 4 of the present invention is located in the area directly above the heat-ins...

Embodiment 3

[0131] See figure 1 , Figure 4 , Embodiment 3 of the present invention discloses a MEMS silicon-based micro-hot plate with thermal insulation grooves, comprising: a single crystal silicon substrate 1; a thermal insulation groove 2 formed on the upper surface of the single crystal silicon substrate 1 and With a certain depth, the thermal insulation groove 2 includes one or more groups of grooves, wherein each group of grooves includes a plurality of linear grooves arranged in parallel; the lower insulating layer 3 covers the thermal insulation groove 2 and the single crystal silicon The upper surface of the substrate 1; the heating layer 4 is arranged on the upper surface of the lower insulating layer 3, and the heating layer 4 is located in the area directly above the heat insulating trench 2; the upper insulating layer 5 covers the The upper surface of layer 4 is heated.

[0132] The heating layer 4 of the present invention is located in the area directly above the heat-in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com