Environment-friendly inkjet printing ink composition for common printing media and raw wallpaper, as well as preparation method and application thereof

A printing medium and inkjet printing technology, applied in the field of printing, can solve the problems of unstable state, flocculation and precipitation of colorants and pigments, affecting the grinding and dispersibility of colorants and pigments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

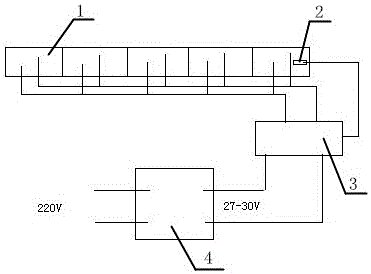

Image

Examples

Embodiment 1

[0103]The environmentally friendly inkjet printing ink composition for common printing media and wallpaper base paper includes 5 grams of pigment yellow C.I.P.Y.12, 5 grams of pigment yellow C.I.P.Y.83, 6 grams of acrylic resin, 3.2 grams of phenolic resin, 15 grams of isopropanol, 15 grams of ethylene glycol butyl ether, 10 grams of propylene glycol methyl ether, 5 grams of dipropylene glycol methyl ether, 5 grams of propylene glycol methyl ether acetate, 10 grams of ethylene glycol methyl ether acetate, 15 grams of butyrolactone, 5 grams of butyl acetate , 0.8 g of Silok-120, a silicon surfactant from Guangzhou, China.

[0104] The preparation method of the environment-friendly inkjet printing ink composition yellow ink used for common printing media and wallpaper base paper adopts the following steps:

[0105] (1) Mix 15 grams of isopropanol, 15 grams of ethylene glycol butyl ether, 10 grams of propylene glycol methyl ether, 5 grams of dipropylene glycol methyl ether, 5 gra...

Embodiment 2

[0110] The environmentally friendly inkjet printing ink composition for common printing media and wallpaper base paper includes 6 grams of pigment blue C.I.P.B.2, 6 grams of pigment blue C.I.P.B.60, 8 grams of acrylic resin, 4 grams of aldehyde and ketone resin, and 10 grams of n-butanol , 15 grams of isobutyl ether, 10 grams of propylene glycol methyl ether, 5 grams of dipropylene glycol ether, 5 grams of isobutyl ester, 10 grams of ethylene glycol methyl ether acetate, 15 grams of butyrolactone, 5 grams of propyl formate, 1 gram of China Silok-51, a silicone surfactant from Guangzhou.

[0111] The preparation method is the same as in Example 1.

Embodiment 3

[0113] The environmentally friendly inkjet printing ink composition for common printing media and wallpaper base paper includes 0.5 grams of pigment red C.I.P.R.48, 0.5 grams of pigment red C.I.P.R.122, 6 grams of maleic anhydride resin, 2.5 grams of phenolic resin, and 15 grams of glycerin Alcohol, 20 grams of ethylene glycol methyl ether, 10 grams of propylene glycol dimethyl ether, 5 grams of dipropylene glycol methyl ether, 5 grams of propylene glycol methyl ether acetate, 10 grams of ethylene glycol methyl ether acetate, 15 grams of butyrolactone, 10 grams Butyl acetate, 0.5 g of Triton X-100 from Rohm and Haas.

[0114] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com