Environment-friendly solvent type dye resin ink-jet printing ink composition applied in common printing medium and preparation method thereof

A printing medium and environmentally friendly solvent technology, applied in the field of environmentally friendly solvent-based dye resin inkjet printing ink composition and its preparation, can solve the problems of ink storage temperature requirements, high price, high equipment operation and maintenance costs, etc., to improve color performance force, improve the bonding adaptability, the effect of low permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

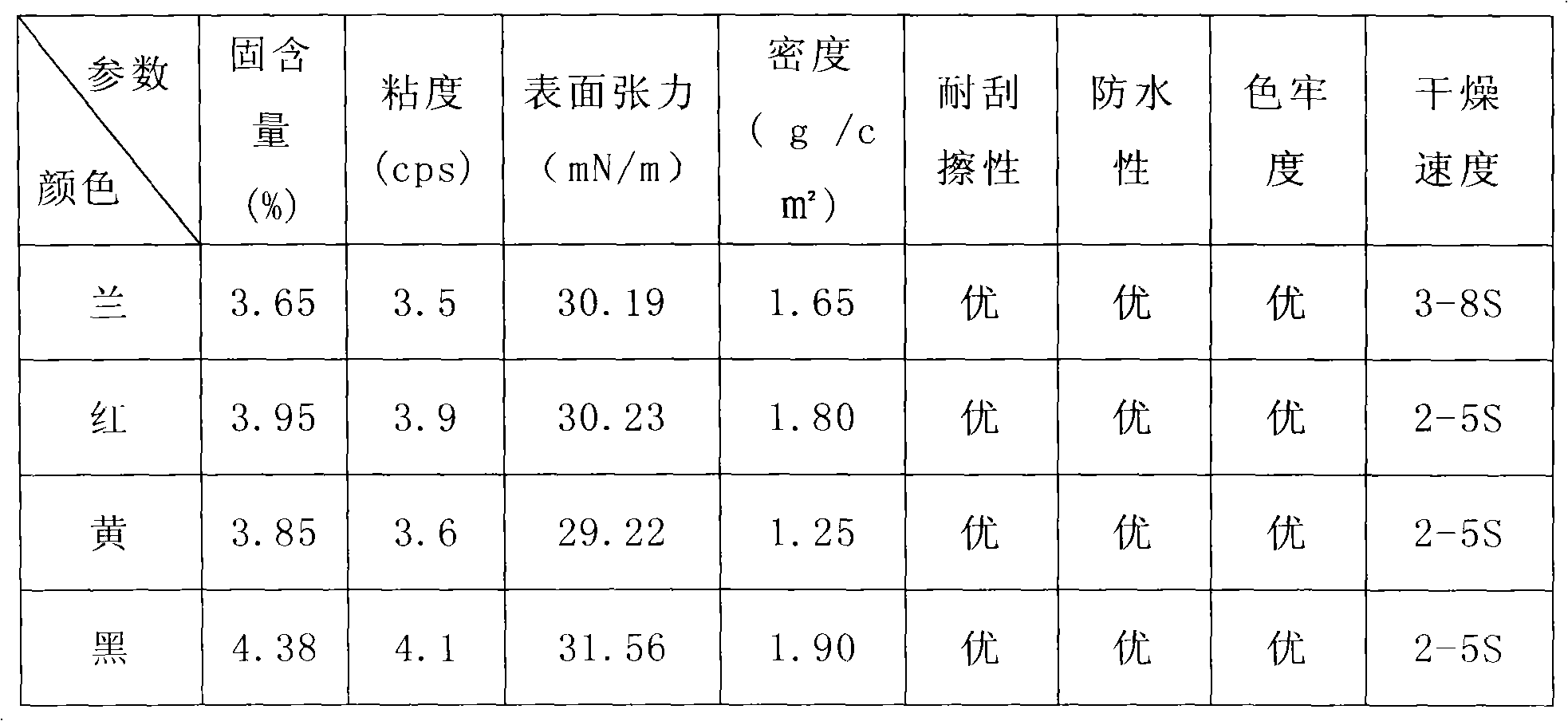

Examples

Embodiment 1

[0056] The environmentally friendly solvent-based dye resin inkjet printing ink composition for ordinary printing media includes 5 grams of Swiss BASF metal complex dye yellow CIPY146, 2 grams of Swiss CLARIANT metal complex dye yellow CIPY79, and 2 grams of acrylic resin , 2 grams of natural synthetic rosin resin, 3.2 grams of phenolic resin, 10 grams of isopropanol, 20 grams of methanol, 10 grams of ethylene glycol butyl ether, 10 grams of diethylene glycol butyl ether, 10 grams of propylene glycol methyl ether, 5 grams of dipropylene glycol Methyl ether, 5 grams of propylene glycol methyl ether acetate, 10 grams of ethylene glycol methyl ether acetate, 5 grams of butyl acetate, 0.8 grams of China Guangzhou Silok silicon surfactant Silok-51.

[0057] The preparation method of the environmentally friendly solvent-based dye resin inkjet printing ink composition applied to ordinary printing media adopts the following steps:

[0058] (1) Combine 10 grams of isopropanol, 20 grams of m...

Embodiment 2

[0063] The environmentally friendly solvent-based dye resin inkjet printing ink composition for ordinary printing media includes 0.6 g of Swiss CLARIANT dye red CIPM127, 0.4 g of Swiss BASF dye red CIPM125, 4 g of aldehyde and ketone resin, and 2.5 g of Malay Anhydride resin, 2 grams of polyester resin, 10 grams of n-propanol, 20 grams of methanol, 10 grams of ethylene glycol methyl ether, 10 grams of diethylene glycol ethyl ether, 10 grams of propylene glycol butyl ether, 5 grams of dipropylene glycol methyl ether, 5 grams Methyl lactate, 10 grams of ethylene glycol methyl ether acetate, 10 grams of butyl acetate, 0.5 grams of Rohm and Haas Triton X-100.

[0064] The preparation method is the same as in Example 1.

Embodiment 3

[0066] The environmentally friendly solvent-based dye resin inkjet printing ink composition for ordinary printing media includes 1.5 g of Taiwan holmium fente DIFENTE's dye blue CIPC41, 4.5 g of Taiwan holmium fente DIFENTE's dye blue CIPC46, and 5.5 g of alkyd Resin, 5.5 grams of acrylic resin, 7 grams of aldehyde and ketone resin, 5 grams of glycerol, 10 grams of isobutanol, 10 grams of ethylene glycol methyl ether, 10 grams of ethylene glycol dibutyl ether, 10 grams of propylene glycol methyl ether, 5 grams Propylene glycol dibutyl ether, 5 grams of propylene glycol methyl ether acetate, 10 grams of ethylene glycol methyl ether acetate, 10 grams of ethyl acetate, 1 gram of China Guangzhou Silok silicon surfactant Silok-120.

[0067] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com