A kind of preparation method of tactical missile motor composite casing

A technology of engines and missiles, which is applied in the field of preparation of functional parts of tactical missiles, can solve the problems of large-strain insulation layer forming, closing and compounding, etc., and achieve the effect of solving bonding technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

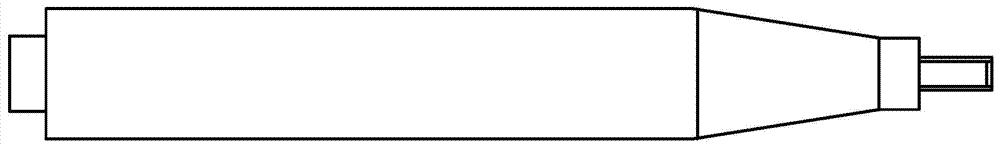

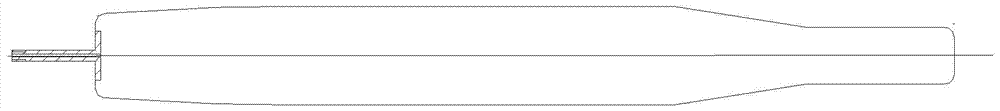

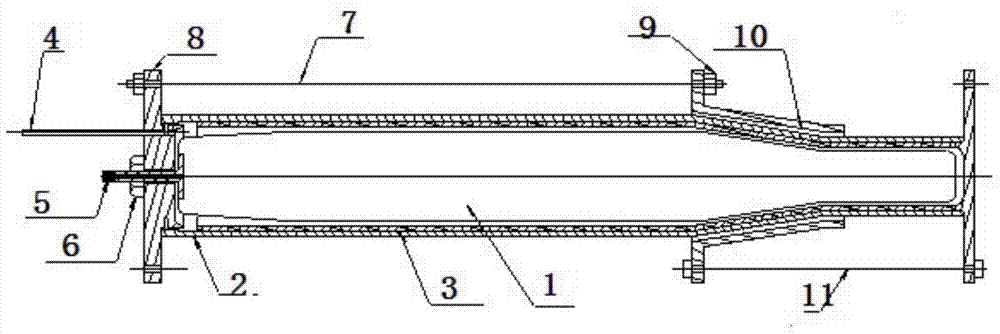

[0030] This embodiment combines figure 1 , 2 The entire production process of the engine composite shell is further explained.

[0031] The winding mandrel of the heat insulation layer is 45# steel, and the surface is coated with polytetrafluoroethylene coating; according to the wall thickness requirements of the heat insulation layer, the diameter of the mandrel matches the inner wall of the heat insulation layer, and the compression margin is about 1mm;

[0032] The airbag is made of silicone rubber, and its outer diameter matches the shape of the winding mandrel, leaving a gap of about 0.2 mm.

[0033] The heat insulating layer material is a high-silica glass cloth barium phenolic resin composite material, which adopts the oblique belt lamination winding molding process, and is assembled into a metal shell after pre-curing, and is heated and pressurized to form a composite shell. The specific steps are as follows :

[0034] Step 1: According to the size of the product, d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com