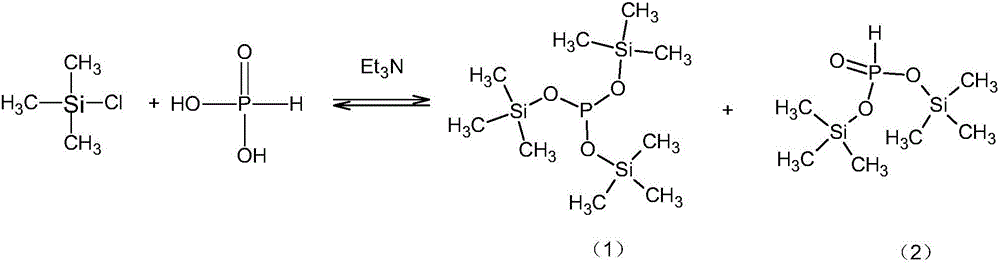

Preparation method of tris(trimethylsilyl)phosphite

A technology of trimethylsilyl and phosphite, which is applied in the field of preparation of high-purity triphosphite, can solve the problems of slow reaction speed, unsatisfactory, harsh application, etc., and achieve rapid reaction, high product quality and simple separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Select tetrahydrofuran as the solvent, add potassium trimethylsiliconate and phosphorus trichloride to the above solvent at a molar ratio of 1:1, stir vigorously during the addition, and filter to remove the chloride Potassium, the above solution is distilled under reduced pressure at 90°C / 20mmHg to obtain the target product, and the purity of the target product can reach more than 99.8%.

Embodiment 2

[0023] Example 2: Select tetrahydrofuran as the solvent, add potassium trimethylsiliconate and phosphorus tribromide to the above solvent at a molar ratio of 1:1, stir vigorously during the addition, and filter to remove the bromide Potassium, the above solution is distilled under reduced pressure at 90°C / 20mmHg to obtain the target product, and the purity of the target product can reach more than 99.7%.

Embodiment 3

[0024] Example 3: Select tetrahydrofuran as the solvent, add sodium trimethylsiliconate and phosphorus trichloride to the above solvent at a molar ratio of 1:1, stir vigorously during the addition, and filter to remove the chloride Sodium, the above solution is distilled under reduced pressure at 90°C / 20mmHg to obtain the target product, and the purity of the target product can reach more than 99.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com