Preparation process for novel chitosan antibacterial fiber

An antibacterial fiber and preparation technology, which is applied in fiber treatment, plant fiber, biochemical fiber treatment, etc., can solve the problems of waste of raw materials, low grafting rate of chitosan and cellulose, etc., achieve less waste of raw materials and ensure antibacterial properties and practicability, the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

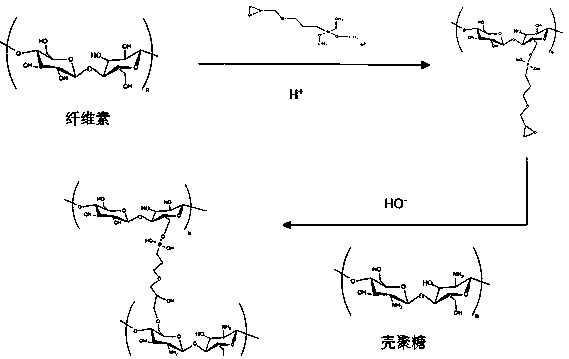

Method used

Image

Examples

Embodiment 1

[0025] A preparation process of a novel chitosan antibacterial fiber, comprising the following steps:

[0026] (1) Preparation of raw materials

[0027] A. In the reaction tank, add cellulose fibers to a sodium hydroxide solution with a concentration of 1-5% to remove surface impurities by soaking for 12-18 hours, wash with clean water to neutrality, dehydrate, and dry to obtain pretreated fibers fiber;

[0028] B. Configure a 4% silane coupling agent kh560 solution, add acetic acid, mix evenly, and adjust the pH to 3-5;

[0029] C. Chitosan solution with a concentration of 2-5%, add sodium hydroxide, mix evenly, and adjust the pH to 9-11; (2) Preparation of silane coupling agent kh560 grafted fibers

[0030] In the reaction tank, soak the cellulose fibers pretreated in step (1)A in the silane coupling agent kh560 solution in step (1)B at a liquor ratio of 1:20, stir evenly, and heat to 60-70°C , kept for 2-6h, washed with water, dehydrated, and dried to obtain silane coupl...

Embodiment 2

[0034] A preparation process of a novel chitosan antibacterial fiber, characterized in that it comprises the following steps:

[0035] (1) Preparation of raw materials

[0036] A. In the reaction tank, the cellulose fibers are added to a sodium hydroxide solution with a concentration of 1% to remove surface impurities by soaking for 12 hours, washed with clean water to neutrality, dehydrated, and dried to obtain pretreated cellulose fibers;

[0037] B. Configure a 4% silane coupling agent kh560 solution, add acetic acid, mix well, and adjust the pH to 3;

[0038] C. Chitosan solution with a concentration of 2%, add sodium hydroxide, mix evenly, and adjust the pH to 9; (2) Preparation of silane coupling agent kh560 grafted fibers

[0039] In the reaction tank, soak the cellulose fibers pretreated in step (1)A in the silane coupling agent kh560 solution in step (1)B at a liquor ratio of 1:20, stir evenly, heat to 60°C, and keep warm 2h, washed with water, dehydrated, and dried...

Embodiment 3

[0043] A preparation process of a novel chitosan antibacterial fiber, characterized in that it comprises the following steps:

[0044] (1) Preparation of raw materials

[0045] A. In the reaction tank, the cellulose fibers are added to a sodium hydroxide solution with a concentration of 5% to remove surface impurities by soaking for 18 hours, washed with clean water to neutrality, dehydrated, and dried to obtain pretreated cellulose fibers;

[0046] B. Configure a 4% silane coupling agent kh560 solution, add acetic acid, mix evenly, and adjust the pH to 5;

[0047]C. Chitosan solution with a concentration of 2-5%, add sodium hydroxide, mix evenly, and adjust the pH to 11; (2) Preparation of silane coupling agent kh560 grafted fibers

[0048] In the reaction tank, soak the cellulose fibers pretreated in step (1)A in the silane coupling agent kh560 solution in step (1)B at a liquor ratio of 1:20, stir evenly, heat to 70°C, and keep warm 6h, washed with clean water, dehydrated,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com