Water-soluble thermal-reactive polyurethane hydrophilic, flame-retardant and antibacterial finishing agent and application thereof

An antibacterial finishing agent, antibacterial finishing technology, applied in flame retardant fiber, fiber treatment, biochemical fiber treatment and other directions, can solve the problems of increasing economic cost, environmental burden of waste liquid, and high concentration of hydrophilic finishing agent process prescription, and achieve The effect of improving the degree of crosslinking, enhancing reactivity and softness, and excellent flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

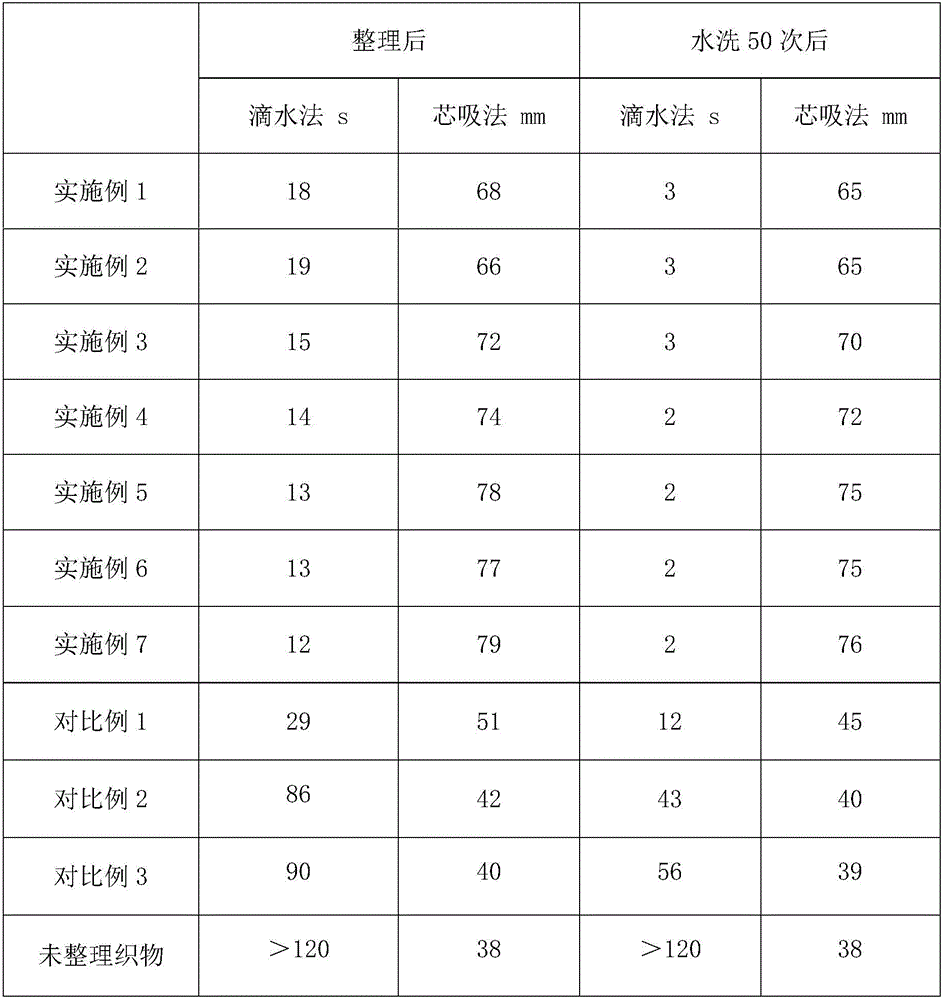

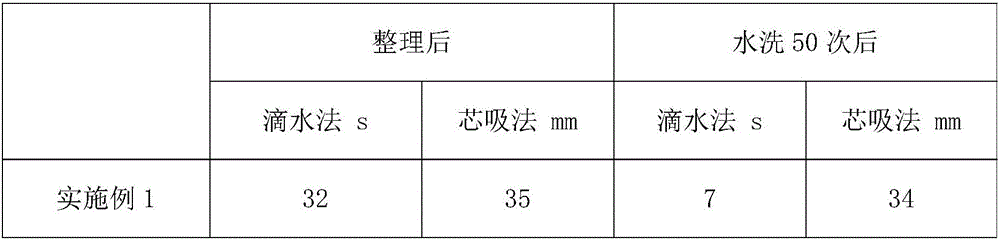

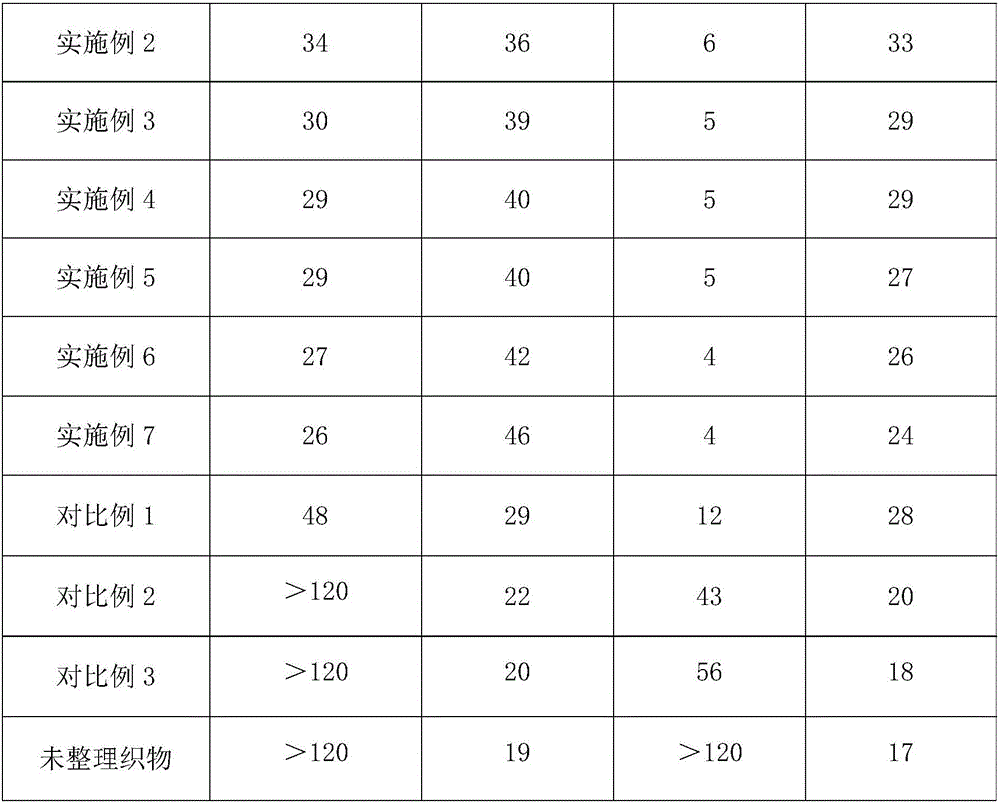

Examples

Embodiment 1

[0039] A water-soluble heat-reactive polyurethane hydrophilic, flame-retardant and antibacterial finishing agent consists of the following components in parts by weight:

[0040] Water-soluble heat-reactive polyurethane: 15 parts;

[0041] Acetylglutamine: 0.1 parts; Glycerin: 2 parts.

[0042] The water-soluble heat-reactive polyurethane is synthesized with isophorone diisocyanate, N-methyldiethanolamine and polypropylene glycol-2000 as main raw materials and methyl ethyl ketone oxime as a blocking agent.

[0043] The finishing liquid formula of the hydrophilic, flame-retardant and antibacterial finishing of the synthetic fiber fabric is:

Embodiment 2

[0045] A water-soluble heat-reactive polyurethane hydrophilic, flame-retardant and antibacterial finishing agent consists of the following components in parts by weight:

[0046] Water-soluble heat-reactive polyurethane: 20 parts;

[0047] Acetylglutamine: 10 parts; Glycerin: 12 parts.

[0048] The water-soluble heat-reactive polyurethane is synthesized with isophorone diisocyanate, N-methyldiethanolamine and polypropylene glycol-2000 as main raw materials and methyl ethyl ketone oxime as a blocking agent.

Embodiment 3

[0050] A water-soluble heat-reactive polyurethane hydrophilic, flame-retardant and antibacterial finishing agent consists of the following components in parts by weight:

[0051] Water-soluble heat-reactive polyurethane: 15 parts;

[0052] Acetylglutamine: 0.5 parts; Glycerin: 4.0 parts.

[0053] The water-soluble heat-reactive polyurethane is synthesized by reacting polyether and isocyanate to obtain a polyurethane prepolymer, and then using sodium bisulfite as a blocking agent to react with the prepolymer.

[0054] The finishing liquid formula of the hydrophilic, flame-retardant and antibacterial finishing of the synthetic fiber fabric is:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com