Technology for treating high-nitrogen, high-carbon and high-chroma organic sewage

An organic sewage, high carbon technology, applied in the treatment of high nitrogen, high chroma organic sewage process, high carbon field, can solve the problems of increasing operating pressure, difficult to control the proportion, high total cost of treatment, to improve the ability to resist shock load, The effect of saving investment, saving construction and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

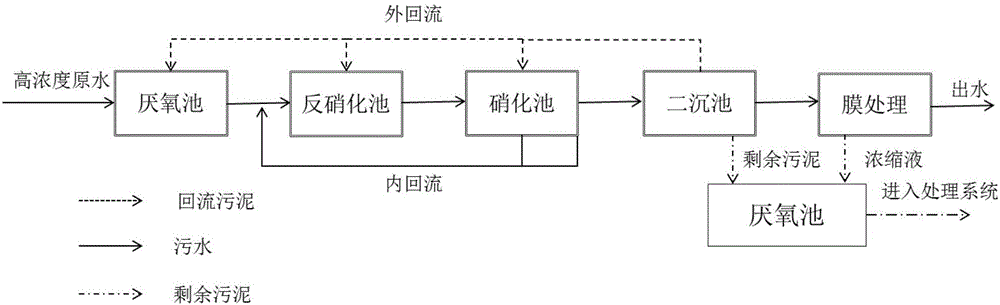

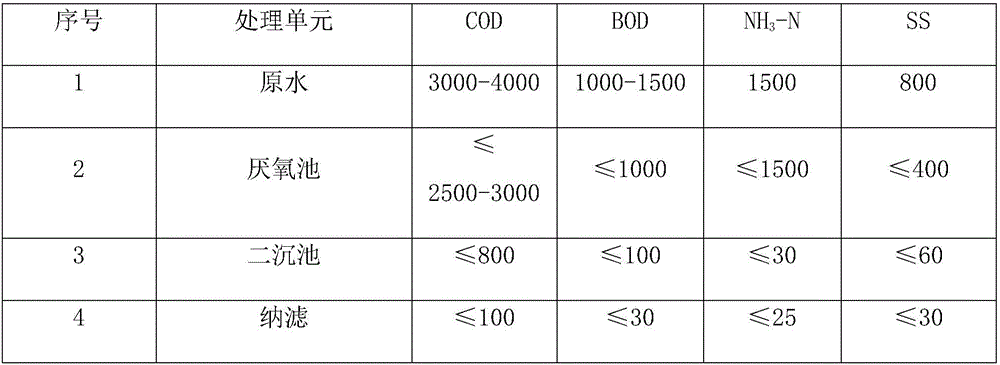

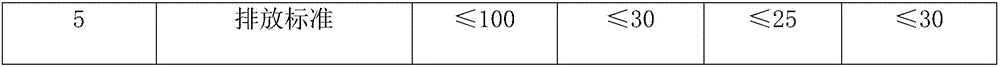

[0086] The process for treating high-nitrogen, high-carbon, and high-color organic sewage is as follows: the organic sewage is treated in an anaerobic tank, denitrification tank, nitrification tank, and secondary sedimentation tank in sequence, and finally the water is discharged after membrane treatment; after nitrification Part of the sewage treated in the tank is returned to the denitrification tank for treatment; the sludge separated from the secondary sedimentation tank is returned to the anaerobic tank, denitrification tank and nitrification tank for process adjustment, and the remaining sludge enters the anaerobic tank.

[0087] Wherein, when part of the sewage treated in the nitrification tank is returned to the denitrification tank for treatment, the reflux ratio is 5-6, and the middle and end of the nitrification tank are provided with pipelines communicating with the return pipeline that returns part of the sewage to the denitrification tank . A baffle is provided i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com