A kind of ion exchanger based on modified resin and preparation method thereof

A technology of ion exchanger and modified resin, applied in ion exchange water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of low reusability, inconvenient operation and low efficiency It can solve the problem of environmental pollution and production safety, simple operation and large adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation of ion exchanger 1 based on modified resin comprises the following steps:

[0028] (1) Dissolve 2 g of Amberlite XAD-4 resin in 10 mL of octanol, then add 30 mL of dichloromethane, add 5 g of anhydrous zinc chloride in batches under stirring, and react at 40 °C for 10 h; After washing with acetone, hydrochloric acid, and distilled water, dry at 60 °C for 8 h to obtain the chloromethylated product;

[0029] (2) Soak 2 g of the chloromethylated product obtained in step (1) in 30 mL of dichloroethane (DCE) for 2 h, then add 2 g of 5-sulfosalicylic acid, and react at 70 °C for 24 h, washed with acetone, hydrochloric acid, and distilled water in sequence, and dried at 60 °C for 8 h to obtain ion exchanger 1; elemental analysis, theoretical value: C, 57.49; H, 4.19; S, 9.58%; experimental value: C, 73.14; H, 5.77; S, 5.27%.

Embodiment 2

[0031] The preparation of ion exchanger 2 based on modified resin comprises the following steps:

[0032] (1) Dissolve 5 g of Amberlite XAD-4 resin in 20 mL of octanol, then add 30 mL of chloromethyl methyl ether, add 10 g of anhydrous aluminum chloride in batches under stirring, and react at 90 °C for 10 h After washing with acetone, hydrochloric acid, and distilled water in sequence, dry at 60 °C for 8 h to obtain the chloromethylated product;

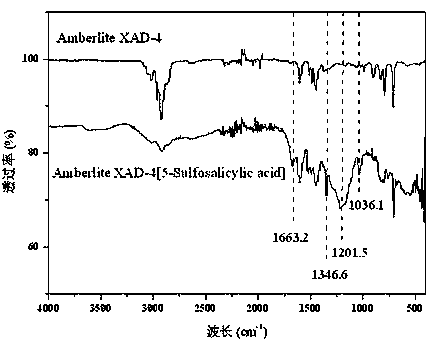

[0033] (2) Soak 1 g of the chloromethylated product obtained in step (1) in 30 mL of nitrobenzene for 2 h, then add 3 g of 5-sulfosalicylic acid, and react at 100 °C for 72 h. After washing with acetone, hydrochloric acid, and distilled water in sequence, they were dried at 60°C for 8 h to obtain ion exchanger 2 (Amberlite XAD-4[5-sulfosalicylicacid]) based on modified resin; elemental analysis, theoretical value: C, 57.49; H, 4.19; S, 9.58%; found: C, 61.13; H, 4.56; S, 8.58%.

[0034] Adopt Fourier transform infrared spectrometer...

Embodiment 3

[0036] The preparation of ion exchanger 3 based on modified resin comprises the following steps:

[0037] (1) Dissolve 4 g of Amberlite XAD-4 resin in 10 mL of octanol, then add 30 mL of dichloromethane, add 5 g of anhydrous aluminum trichloride in batches under stirring, and react at 40 °C for 10 h, After washing with acetone, hydrochloric acid, and distilled water in sequence, dry at 60 °C for 8 h to obtain the chloromethylated product;

[0038](2) Soak 3 g of the chloromethylated product obtained in step (1) in 30 mL of N-N-dimethylformamide (DMF) for 2 h, then add 5 g of 5-sulfosalicylic acid, at 100 Reaction at ℃ for 72 h, followed by washing with acetone, hydrochloric acid and distilled water, and drying at 60 ℃ for 8 h to obtain ion exchanger 3 based on modified resin; elemental analysis, theoretical value: C, 57.49; H, 4.19 ; S, 9.58%; Experimental value: C, 65.99; H, 5.05; S, 7.24%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com