Pre-prepared alloy powder type flux-cored wire and self-protection open arc surfacing welding method of high-chromium alloy

A technology of flux-cored welding wire and alloy powder, applied in welding medium, welding equipment, welding equipment, etc., can solve the problems of affecting the service life of wear-resistant workpieces and peeling of the surfacing layer, so as to improve the deposition efficiency and improve the wear resistance. , the effect of improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

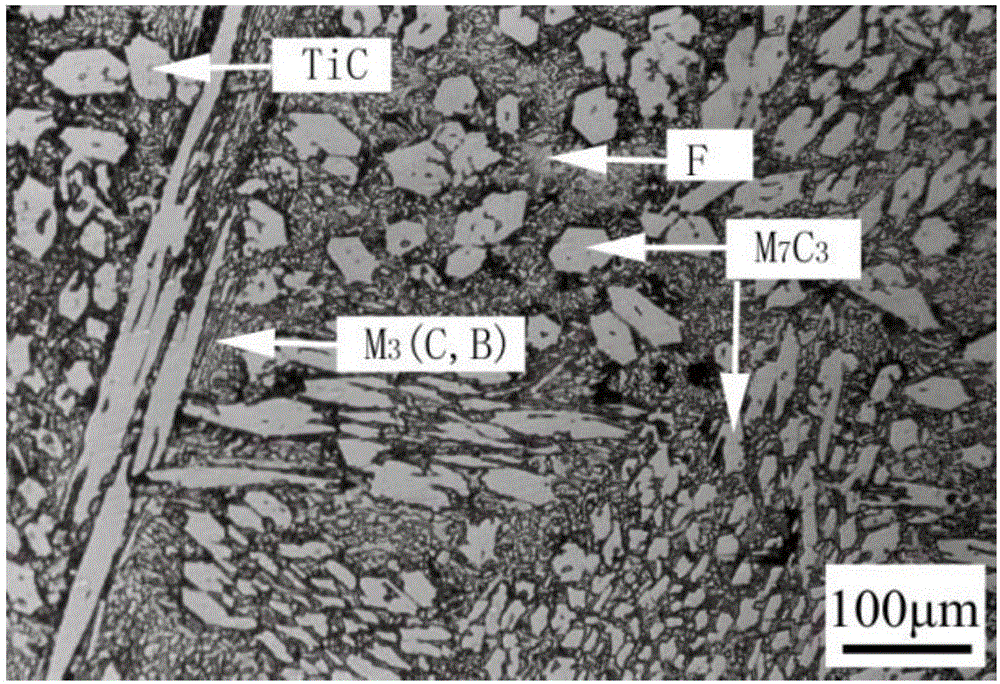

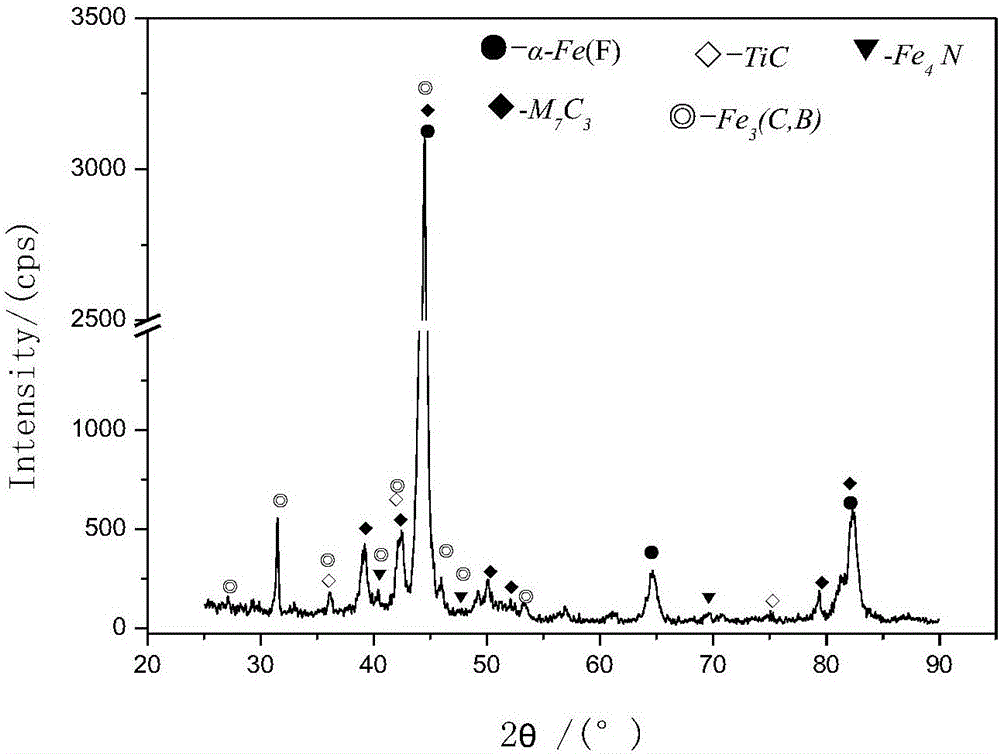

[0071] Combined with the accompanying drawings, high-carbon ferrochromium, ferrosilicon, graphite, ferrovanadium and other alloy powders are weighed according to the composition ratio requirements of the flux-cored wire powder core during production, and all powders are passed through a 60-mesh sieve. The flux-cored welding wire is prepared and formed on the YHZ-1 flux-cored welding wire forming machine manufactured by a limited company. The outer sheath of the flux-cored wire is H08A cold-rolled steel strip (width 16mm×thickness 0.36mm, the same below), and the sheath is equipped with iron alloy, graphite, carbide and metal powder to form a powder core. The mass percentage of the powder core composition is: High-carbon ferrochrome 65%, ferrosilicon 9%, flake graphite 8%, ferro-vanadium 8%, medium-carbon ferromanganese 4%, ferromolybdenum 2%, TiC 2%, reduced iron powder 2%, the filling rate of the powder core 45%. The components of the powder core are stirred evenly and then ...

Embodiment 2

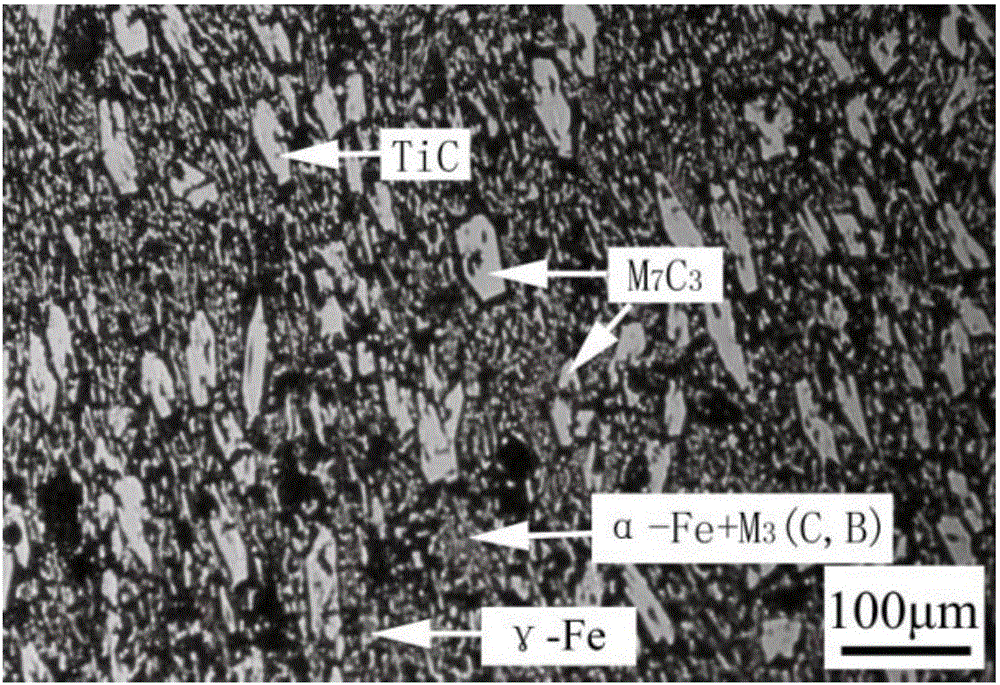

[0078]Combined with the accompanying drawings, high-carbon ferrochromium, ferrosilicon, graphite, ferrovanadium and other alloy powders are weighed according to the composition ratio requirements of the flux-cored wire powder core during production, and all powders are passed through a 60-mesh sieve. The flux-cored welding wire is prepared and formed on the YHZ-1 flux-cored welding wire forming machine manufactured by a limited company. The outer sheath of the flux-cored wire is H08A cold-rolled steel strip (16mm×0.36mm), and the sheath is equipped with iron alloy, graphite, carbide and metal powder to form a powder core. The composition (mass percentage) of the powder core is: high carbon 60% ferrochrome, 10% ferrosilicon, 7% flake graphite, 6% ferrovanadium, 3% medium carbon ferromanganese, 3% ferromolybdenum, 3% TiC, 8% reduced iron powder, the filling rate of the powder core is 47% %. The components of the powder core are stirred evenly and then rolled into Φ4.4 flux-core...

Embodiment 3

[0081] Combined with the accompanying drawings, during production, weigh and weigh high-carbon ferrochrome, ferrosilicon, graphite, ferrovanadium and other alloy powders according to the composition ratio requirements of the flux-cored wire powder core, and all the powders are passed through a 60-mesh sieve. The flux-cored welding wire is prepared and formed on the YHZ-1 flux-cored welding wire forming machine manufactured by a limited company. The outer sheath of the flux-cored wire is H08A cold-rolled steel strip (16mm×0.36mm), and the sheath is equipped with iron alloy, graphite, carbide and metal powder to form a powder core. The composition (mass percentage) of the powder core is: high carbon 63% ferrochrome, 8% ferrosilicon, 9% flake graphite, 7% ferrovanadium, 5% medium carbon ferromanganese, 3% ferromolybdenum, TiC 2%, reduced iron powder 3%, the filling rate of the powder core is 46 %. The components of the powder core are stirred evenly and then rolled into Φ4.4 flu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com