Hollow Water Outlet Ultrasonic Electric Spindle

An ultrasonic and electro-spindle technology, applied in metal processing equipment, metal processing machinery parts, work accessories, etc., can solve the problem of difficult chip removal, and achieve the effect of improving cutting heat, long service life and increasing tool life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

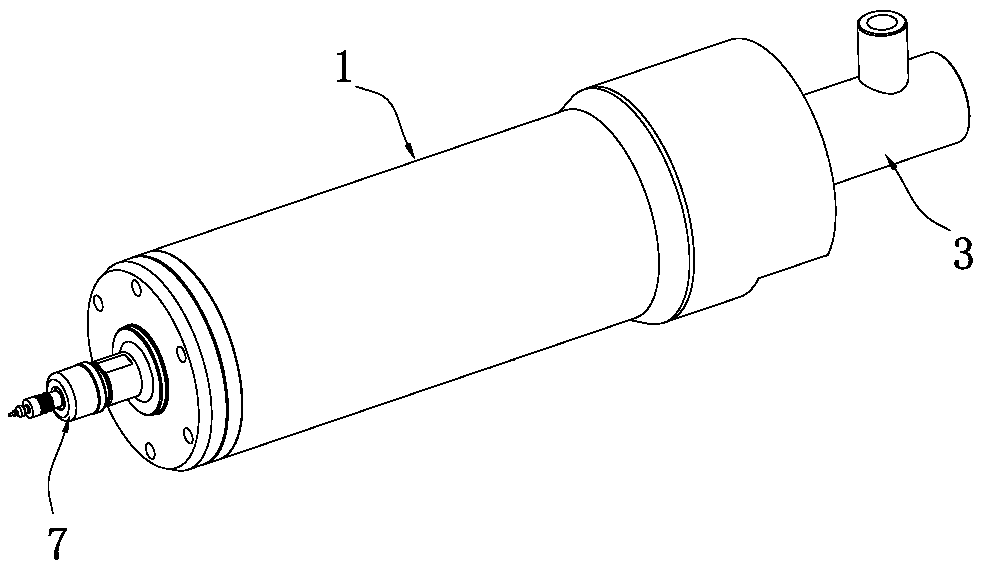

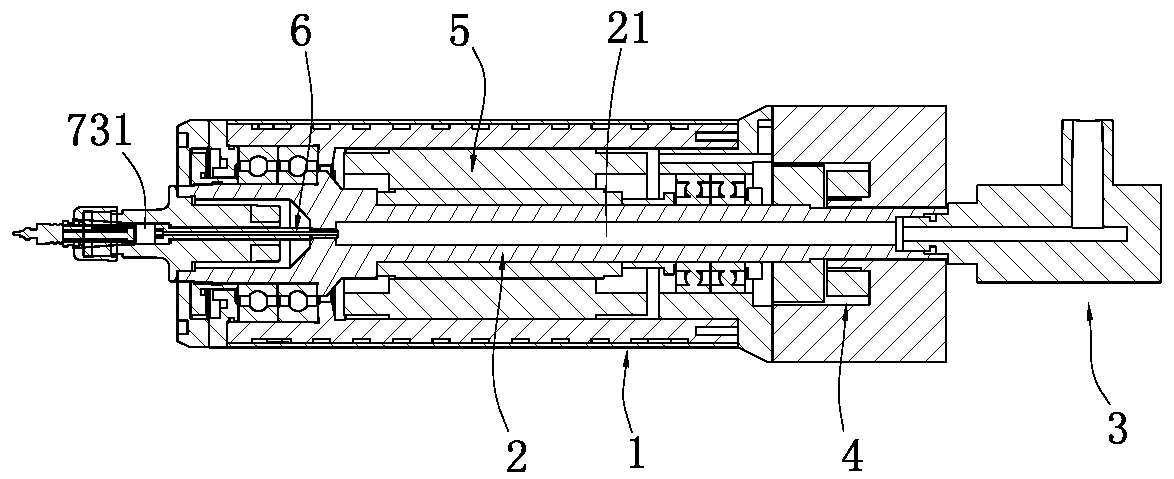

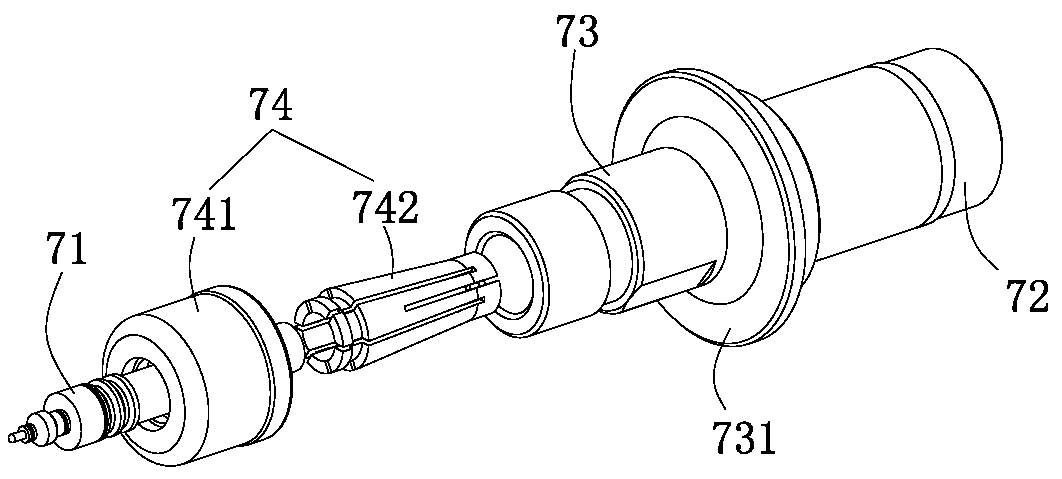

[0019] Example: see figure 1 , figure 2 with image 3 , a hollow water outlet ultrasonic electric spindle provided by the present invention includes a spindle housing 1, a spindle rotor 2, a hollow water outlet rotary joint 3, a wireless power transmission module 4, a squirrel cage motor 5, a hollow water outlet connecting pipe 6 and a hollow water outlet switch energy device 7, the squirrel-cage motor 5 is arranged in the main shaft housing 1, the main shaft rotor 2 runs through the rotating shaft of the squirrel-cage motor 5 and is arranged in the main shaft housing 1 through a bearing assembly, and the main shaft rotor 2 is provided with a The water delivery channel 21 whose axis line extends, the hollow water outlet transducer 7 is arranged on the head of the main shaft housing 1, and is connected to the head end of the water delivery channel 21 through the hollow water outlet connecting pipe 6, the hollow The water outlet rotary joint 3 is arranged at the end of the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com