Preparation method for test sample for alloy powder performance analysis and special compound crucible

A technology of alloy powder and test sample, which is applied in the field of metal powder detection and analysis, can solve the problems that the alloy powder cannot be directly tested, and the alloy powder is difficult to be heated by induction, so as to achieve the effect of ensuring uniformity, easy grasp, and no cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

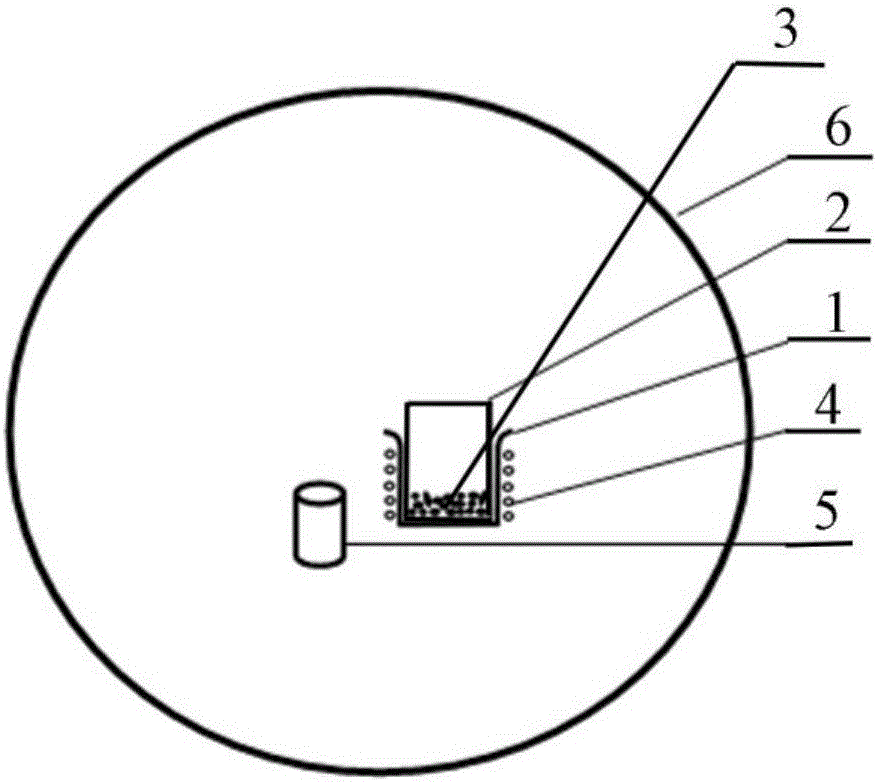

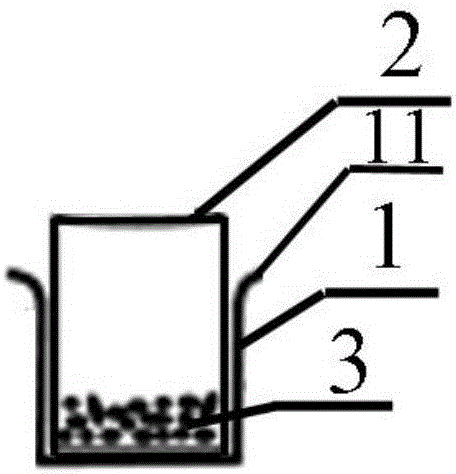

Image

Examples

Embodiment 1

[0047] (1) Powder sample preparation: take alloy powder that has not been treated by induction heating ceramic crucible in a high-frequency furnace (choose 316L stainless steel alloy powder, alloy powder composition: C: 0.025, Si: 0.32, Mn: 0.15, P: 0.01, S: 0.0051, Cr: 16.28, Ni: 12.10, Mo: 2.55) 90 grams;

[0048] (2) Crucible preheating: put the ceramic crucible into the muffle furnace to preheat to 200°C and keep it warm for 2 hours;

[0049] (3) Load the powder sample: put 90 grams of the alloy powder prepared in step (1) into the preheated ceramic crucible, and shake it gently by hand (the purpose is to make the contact between the powder particles closer) to make the alloy powder Vibrate, and then put the ceramic crucible into the graphite sleeve on the induction coil of the high-frequency induction furnace;

[0050] (4) Vacuumizing and smelting: close the furnace cover of the high-frequency induction heating furnace, and vacuumize to 10 -4 Pa, and then filled with hi...

Embodiment 2

[0057] (1) Powder sample preparation: take the alloy powder that has not been processed by induction heating ceramic crucible in a high-frequency furnace (choose 17-4PH alloy powder, alloy powder composition: C: 0.034, Si: 0.35, Mn: 0.17, P: 0.014, S : 0.007, Cr: 16.32, Ni: 4.13, Cu: 4.01, Nb: 0.32) 90 grams;

[0058] (2) Crucible preheating: put the ceramic crucible into the muffle furnace to preheat to 200°C and keep it warm for 2 hours;

[0059] (3) Load the powder sample: put 90 grams of the alloy powder prepared in step (1) into the preheated ceramic crucible, vibrate the alloy powder gently by hand, and then put the ceramic crucible into the high-frequency induction furnace for induction In the graphite sleeve on the coil;

[0060] (4) Vacuumizing and smelting: close the furnace cover of the high-frequency induction heating furnace, and vacuumize to 10 -4 Pa, then filled with high-purity argon protection, under the protection of argon, the alloy powder is melted, the m...

Embodiment 3

[0067] (1) Powder sample preparation: take the alloy powder that has not been treated by induction heating the ceramic crucible in a high-frequency furnace (select XY05 alloy powder, alloy composition: Si: 1.11, Cr: 7.64, Ni: 4.03, Mo: 11.52, Co: 10.82) 90 grams;

[0068] (2) Crucible preheating: put the ceramic crucible into a muffle furnace to preheat to 200°C and keep it warm for 2 hours;

[0069] (3) Load the powder sample: put 90 grams of the alloy powder prepared in step (1) into the preheated ceramic crucible, vibrate the alloy powder gently by hand, then put the ceramic crucible into the graphite sleeve, and then Place the ceramic crucible with the graphite sleeve on the outside in the induction coil of the high-frequency induction furnace;

[0070] (4) Vacuumizing and smelting: close the furnace cover of the high-frequency induction heating furnace, and vacuumize to 10 -4 Pa, then filled with high-purity argon protection, under the protection of argon, the alloy pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com