Touch screen cover plate and manufacturing method thereof

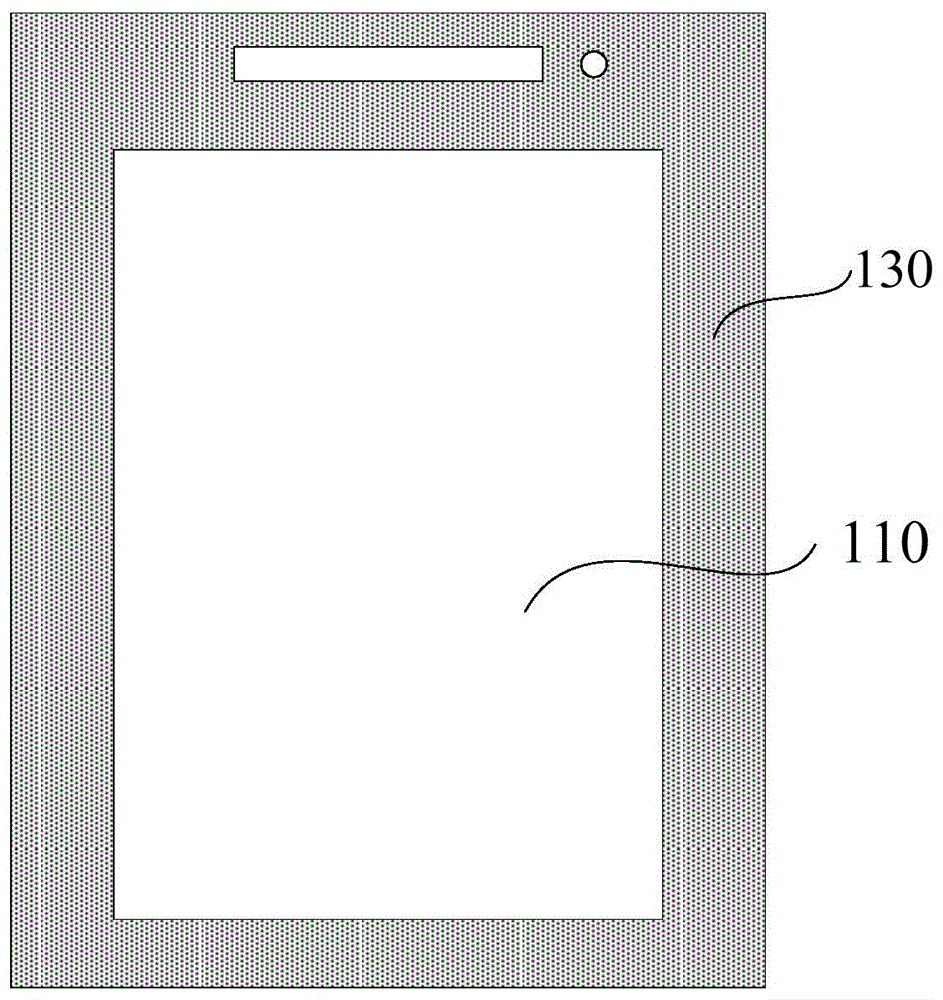

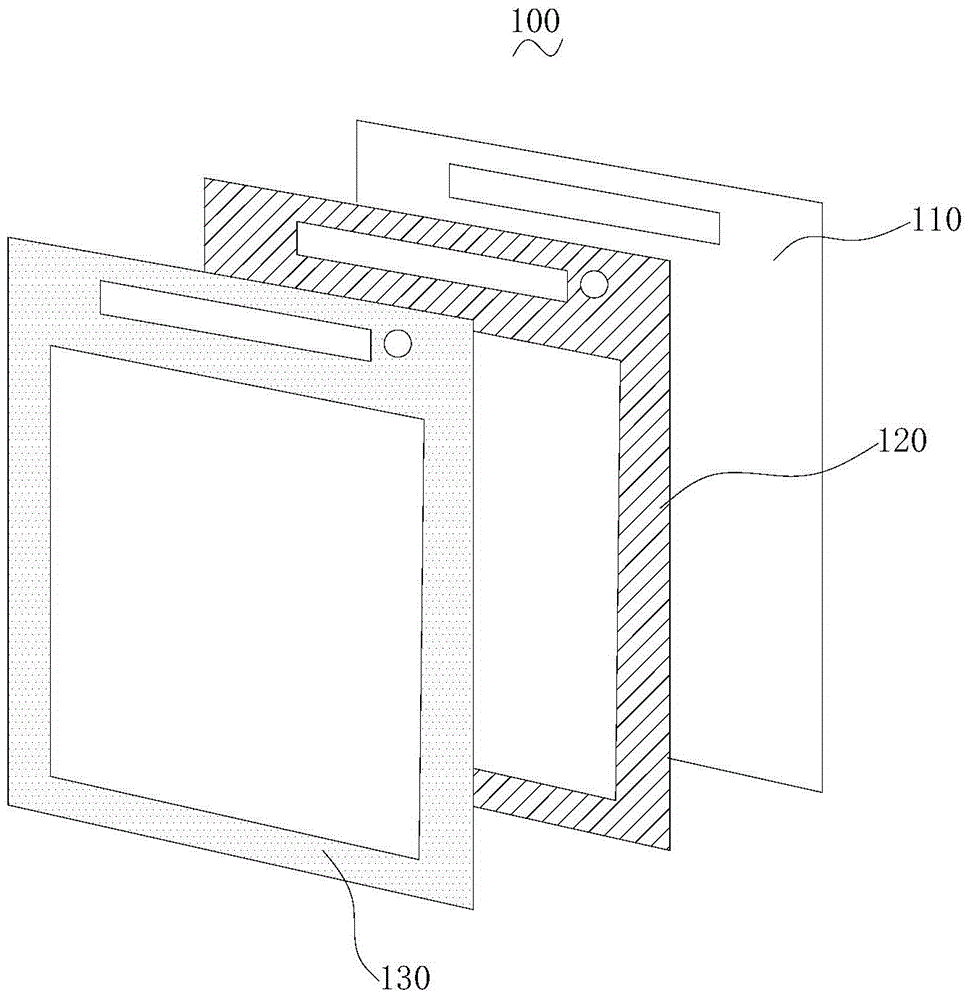

A touch screen and cover technology, which is applied in the input/output process of instruments, electrical digital data processing, data processing, etc., can solve the problems of dull touch screen cover and dull ink gloss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

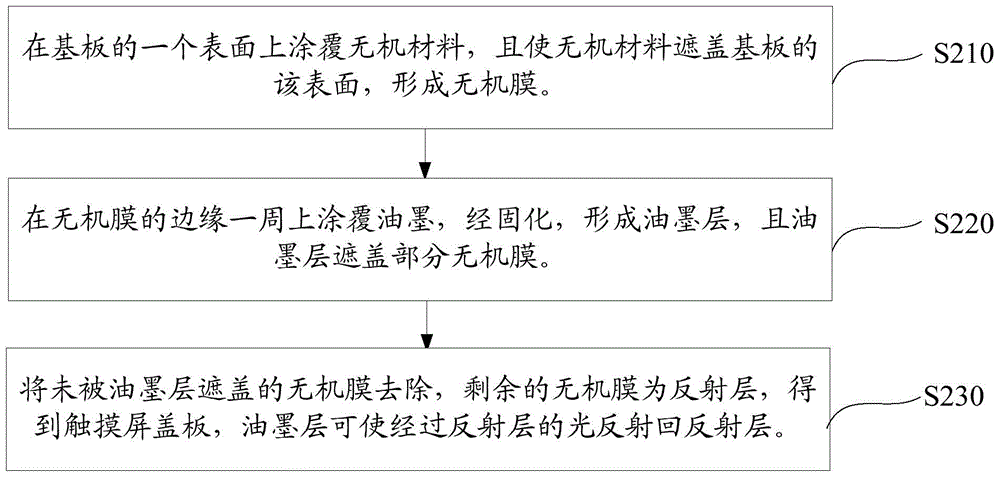

[0048] like image 3 As shown, the method for preparing a touch screen cover in one embodiment can be used to prepare the above touch screen cover. The preparation method of the touch screen cover plate of the present embodiment includes the following steps:

[0049] Step S210: coating an inorganic material on one surface of the substrate, and making the inorganic material cover the surface of the substrate to form an inorganic film.

[0050] Wherein, the substrate is a glass plate, a quartz plate, an alumina plate or a transparent organic plate. Please also refer to Figure 4 , Figure 4 is a schematic structural diagram of the substrate 300 .

[0051] The thickness of the substrate is 0.01-10 mm; preferably, the thickness of the substrate is 0.1-5 mm; more preferably, the thickness of the substrate is 0.3-2 mm.

[0052] Please also refer to Figure 5 and Figure 6 After one surface of the substrate 300 is coated with an inorganic material, an inorganic film 400 is for...

Embodiment 1

[0079] The preparation steps of the touch screen cover plate of the present embodiment are as follows:

[0080] (1) Evaporate aluminum oxide on one surface of a glass substrate with a thickness of 0.1 mm by vacuum thermal evaporation, and cover the surface of the glass substrate with the evaporated aluminum oxide to form an aluminum oxide film with a thickness of 10 microns.

[0081] (2) Screen-print heat-curing ink on the edge of the aluminum oxide film, and cure it at 100°C for 30 minutes to form an ink layer with a thickness of 1 mm along the edge of the substrate, so that the ink layer covers part of the inorganic membrane.

[0082] (3) Use the stripping agent to spray the substrate for 10 minutes to remove the inorganic film not covered by the ink layer, and the remaining inorganic film is the reflective layer. After cleaning, continue to complete the subsequent steps according to the design requirements to obtain the touch screen cover , wherein, the stripping agent inc...

Embodiment 2

[0085] The preparation steps of the touch screen cover plate of the present embodiment are as follows:

[0086] (1) Titanium dioxide is sputtered on one surface of a quartz substrate with a thickness of 5 mm by magnetron sputtering, and the surface of the substrate is covered by the sputtered titanium dioxide to form a titanium dioxide film with a thickness of 300 nanometers.

[0087] (2) Screen-print thermosetting ink along the edge of the titanium dioxide film, and cure it at 200°C for 10 minutes to form an ink layer with a thickness of 1 nanometer and along the edge of the substrate, so that the ink layer covers part of the inorganic film .

[0088] (3) Soak the substrate in a stripping tank filled with a stripping agent, soak for 0.5 to 10 minutes under ultrasonic conditions with an intensity of 60KHz, remove the inorganic film that is not covered by the ink layer, and the remaining inorganic film is the reflective layer , after cleaning, continue to complete the follow-u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com