Method for producing liquid fertilizer containing secondary trace elements by water washing treatment of blast furnace slag

A technology of trace element and water washing treatment, applied in the field of liquid fertilizer, can solve the problems of drug residues, infection of the bottom mud of aquaculture ponds, human injury, etc., to increase the concentration and alkaline concentration, save the cost of solidification and landfill, and improve the effect of buffering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

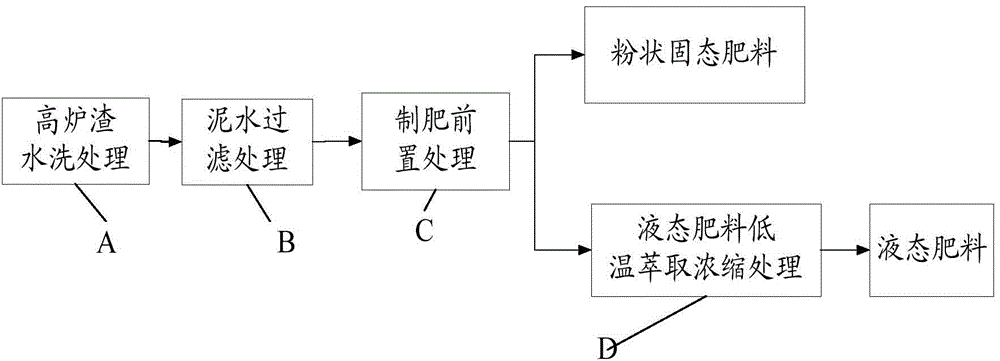

[0047] First, see figure 1 , figure 1 It is a flow chart of the method for producing liquid fertilizer containing secondary trace elements by washing the blast furnace slag in this embodiment.

[0048] This embodiment provides a method of washing blast furnace slag with water to produce liquid fertilizer containing secondary trace elements, and its implementation steps include:

[0049] A. Washing treatment of blast furnace slag: wash the blast furnace slag produced after steelmaking in a consistent operation steelmaking plant, and the blast furnace slag contains at least one of desulfurization slag or blast furnace slag. The desulfurization slag and blast furnace slag contain Strongly basic base and containing calcium oxide, silicon oxide, magnesium oxide, potassium oxide, boron, iron, manganese, molybdenum, phosphoric anhydride, copper, zinc and nitrogen and many other trace elements, the blast furnace slag contained in it after washing The sediment will be mixed in the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com