S-SnO2/Ti3C2 two-dimensional nano lithium ion battery cathode material and preparation method thereof

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, nanotechnology, etc., can solve problems such as low strength and weak van der Waals force, and achieve the effect of improving electric capacity and relieving powder agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

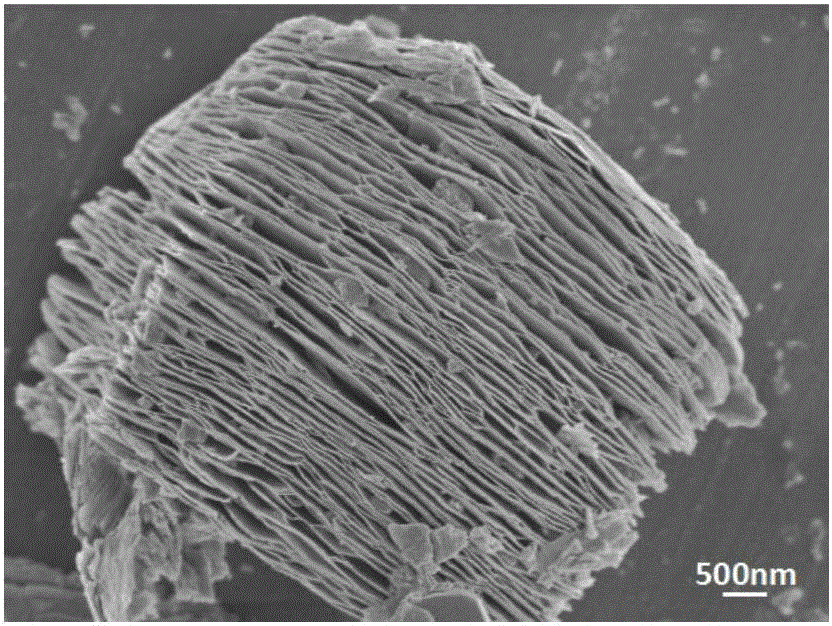

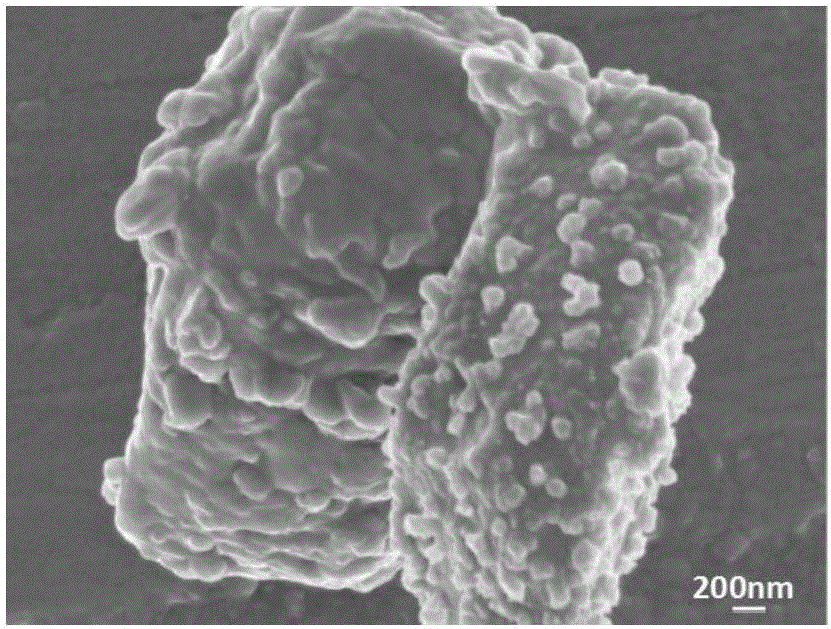

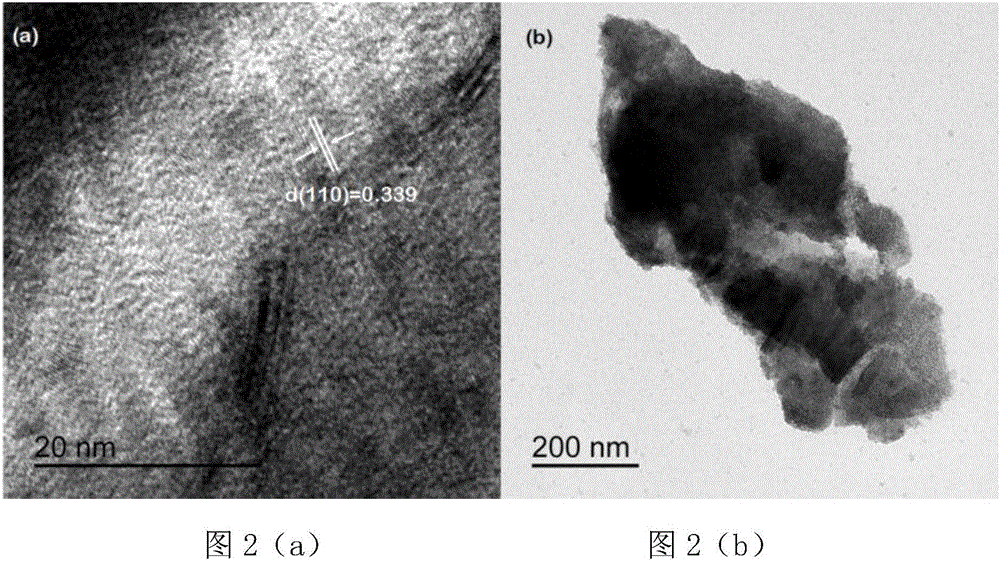

[0021] A kind of S-SnO of this embodiment 2 / Ti 3 C 2 Two-dimensional nano-lithium ion battery negative electrode materials, including two-dimensional layered material Ti 3 C 2 , the two-dimensional layered material Ti 3 C 2 The interlayer and surface are loaded with granular tin dioxide, and the surface is coated with sulfur.

[0022] This embodiment includes the following steps:

[0023] (1) The ternary layered Ti 3 AlC 2 High-energy ball milling of ceramic powder for 4 hours, rotating speed 400r / min, ball-to-material ratio 10:1, drying at 60°C after refining the powder, to obtain Ti with a particle size of 8-10μm 3 AlC 2 ceramic powder;

[0024] (2) Ti obtained in step (1) 3 AlC 2 Take 2g of the ceramic powder and immerse it in 100mL of 40wt% hydrofluoric acid solution to react for 48h; stir, and centrifuge and wash the corrosion products with deionized water until the pH of the centrifuged supernatant is 5; then wash with absolute ethanol for 3 times ; The res...

Embodiment 2

[0028] A kind of S-SnO of this embodiment 2 / Ti 3 C 2 Two-dimensional nano-lithium ion battery anode material, two-dimensional layered material Ti 3 C 2 The interlayer and surface are loaded with granular tin dioxide, and the surface is coated with sulfur.

[0029] This embodiment includes the following steps:

[0030] (1) The ternary layered Ti 3 AlC 2 High-energy ball milling of ceramic powder for 4 hours, rotating speed 400r / min, ball-to-material ratio 10:1, drying at 40°C after refining the powder, to obtain Ti with a particle size of 20-50μm 3 AlC 2 ceramic powder;

[0031] (2) Ti obtained in step (1) 3 AlC 2 Take 2g of ceramic powder and immerse it in 50mL of 40wt% hydrofluoric acid solution to react for 48h; stir, and centrifuge and wash the corrosion products with deionized water until the pH of the centrifuged supernatant is 5; then wash with absolute ethanol for 3 times ; The resulting solid sample is dried to obtain a two-dimensional layered nanomaterial ...

Embodiment 3

[0034] A kind of S-SnO of this embodiment 2 / Ti 3 C 2 Two-dimensional nano-lithium ion battery anode material, two-dimensional layered material Ti 3 C 2 The interlayer and surface are loaded with granular tin dioxide, and the surface is coated with sulfur.

[0035] This embodiment includes the following steps:

[0036] (1) The ternary layered Ti 3 AlC 2 High-energy ball milling of ceramic powder for 3 hours, speed of 400r / min, ball-to-material ratio of 10:1, drying at 50°C after refining the powder, to obtain Ti with a particle size of 30-60μm 3 AlC 2 ceramic powder;

[0037] (2) Ti obtained in step (1) 3 AlC 2 Take 3g of ceramic powder and immerse it in 60mL of 40wt% hydrofluoric acid solution to react for 24h; stir, and centrifuge and wash the corrosion products with deionized water until the pH of the centrifuged supernatant is 6; then wash with absolute ethanol for 3 times ; The resulting solid sample is dried to obtain a two-dimensional layered nanomaterial Ti ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com