Lithium anode for high-specific-energy secondary battery

A secondary battery and anode technology, applied in battery electrodes, fuel cell half-cells, primary battery half-cells, lithium batteries, etc., can solve the problem that lithium dendrites cannot achieve high cycle life and high safety at the same time, Low coulombic efficiency, short cycle life and other issues to achieve the effect of preventing polysulfide shuttle effect, overcoming easy cracking, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

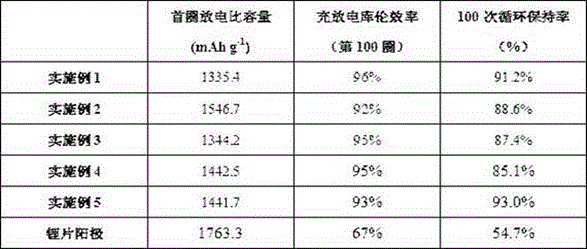

Embodiment 1

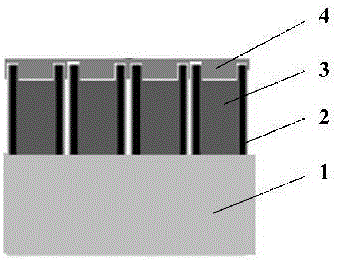

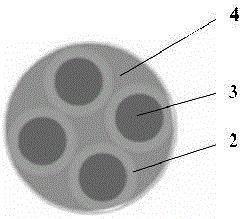

[0025] With copper as the conductive substrate, a layer of Ti is electrodeposited on the copper substrate, and then in 1%HF+0.5%NH 4 F+H 2 Formation of Cu-based TiO by anodic oxidation in O mixed solution 2 Nanotube array structure, Cu-based TiO 2 The nanopipe diameter size is about 10nm. Directional deposition of Li on Cu-based TiO by electrodeposition under inert atmosphere 2 In nanotubes, and coated with MOF metal organic framework barrier layer at the mouth of the tube, a high specific energy lithium anode (Cu / Li-TiO 2 / MOF).

Embodiment 2

[0027] CuZn alloy is a conductive substrate, and Fe grows on this conductive substrate 2 o 3 Nanotube array, the diameter of the nanotube is about 100nm, the Li is pressed into the base Fe by mechanical extrusion in the glove box 2 o 3 nanotubes, and coated with COF metal-organic framework barrier layer at the mouth of the tube, the directional growth / dissolution lithium anode (Cu / Li-Fe 2 o 3 / MOF).

Embodiment 3

[0029] Copper is used as the conductive substrate, and Al is grown on the copper substrate 2 o 3 Nanotube array, Cu-based Al 2 o 3 The nanotube diameter size is about 30nm. Directional deposition of Li on Cu-based Al by electrodeposition in a nitrogen atmosphere with an oxygen content below 5 ppm 2 o 3 nanotubes, and coated with LiClO 4 -PEO solid electrolyte material as a barrier layer to make directional growth / dissolution lithium anode (Cu / Li-TiO 2 / MOF).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com