A Medium Voltage Cast Transformer with Combined Insulation

A combined insulation and castable technology, applied in the field of transformers, can solve the problems of affecting the effect of vacuum degassing, the viscosity of castables, and easy cracking, etc., and achieve the effects of improving product qualification rate, good toughness, and improving electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

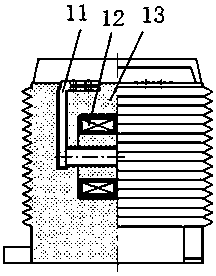

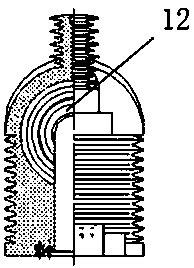

[0019] Figure 2-1 It is a structural schematic diagram of the medium voltage casting type current transformer of the present invention. Figure 2-2 and Figure 2-3 It is a structural schematic diagram of the medium voltage casting type voltage transformer of the present invention.

[0020] A medium-voltage casting transformer with combined insulation, including a primary winding 1, a secondary winding 2 and an insulating layer 3, and a semiconductor crepe paper shielding layer 5 is wrapped around the primary winding and the secondary winding, and is located between the primary winding and the secondary winding The insulation layer 3 of the main insulation part is vacuum-dried, then vacuum-injected at room temperature and degassed after vacuum stirring and degassing. It has excellent electrical properties, fluidity and toughness. After curing, it form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com