Method for determining performance of high-temperature sulfur corrosion prevention coating of water-cooling wall of boiler

A measurement method and water-cooled wall technology, applied in the fields of weather resistance/light resistance/corrosion resistance, measuring devices, strength characteristics, etc., can solve problems such as lack of anti-corrosion effect, waste of engineering costs, lack of understanding of spraying technology in thermal power plants, etc. To achieve good anti-high temperature sulfur corrosion effect, durable protection, and beneficial to industry rectification and healthy development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

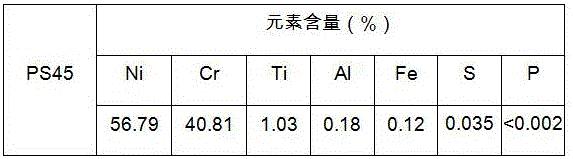

[0044] In this example, a thermal power plant has carried out high-temperature sulfur-corrosion-resistant spraying on the water wall as an example. The spraying material is PS45 (which belongs to the NiCrTi series spraying material). The spraying construction is carried out by the supersonic arc spraying method widely used at present. The invention is used to measure the performance of the anti-high temperature sulfur corrosion coating of the water wall, and the measurement standards and processes are as follows.

[0045] 1) Analysis of chemical composition of raw materials: The Cr content in the coating material wire should reach more than 40%, and the Ni content should reach more than 50%.

[0046] The main reason is: because it contains more than 40% Cr element, a stable chromium oxide dense protective film will be formed during the spraying process, which can intercept the corrosion medium from entering the coating. The Ni element containing more than 50% will have super ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com